Easy-cutting nylon EVOH high-barrier film and production method thereof

A nylon, high-resistance technology, applied in the field of nylon EVOH high-resistance barrier film, can solve the problems of weak film heat sealing strength, easy to cause adhesion, high production cost, etc., to achieve enhanced heat sealing effect, good sealing effect, and strong anti-pollution ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

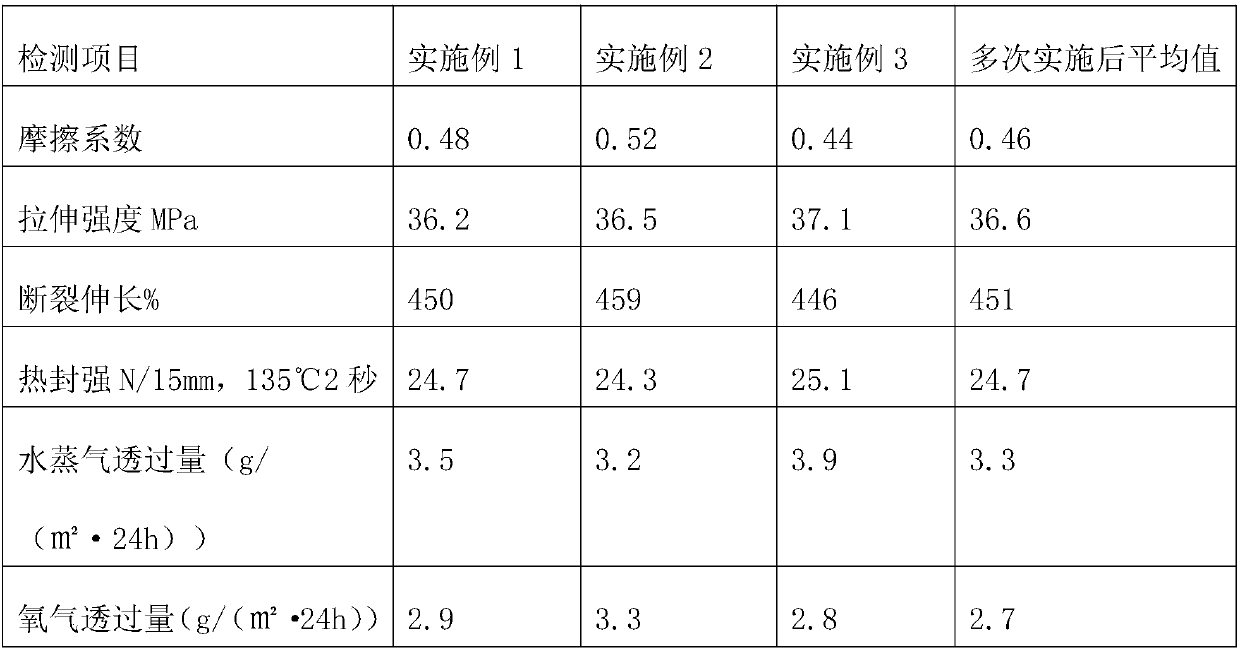

Embodiment 1

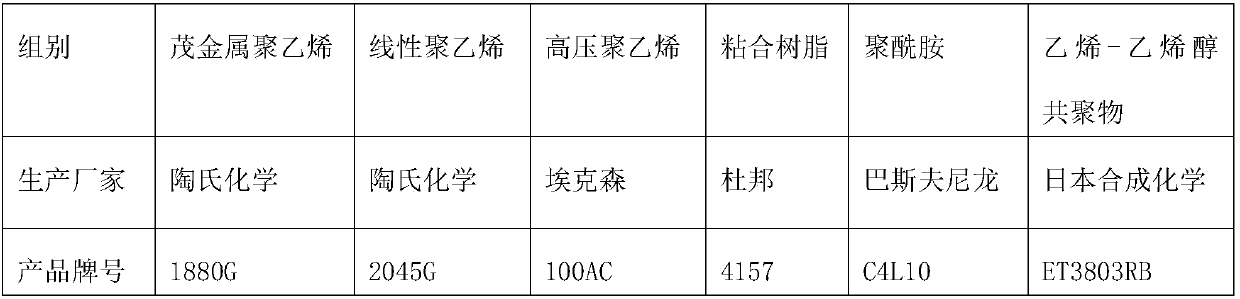

[0026] Add the materials of the first PE film layer, the first adhesive film layer, the first PA film layer, the middle EVOH film layer, the second PA film layer, the second adhesive film layer and the second PE film layer to the seven-layer Melting in the barrel of a co-extrusion blown film machine, blowing the film after co-extrusion, cooling and shaping to obtain the nylon EVOH high barrier film;

[0027] Wherein the mass ratio of metallocene polyethylene, linear polyethylene and high-pressure polyethylene in the first PE film layer and the second PE film layer is 45:30:30;

[0028] The melt temperature of the first PE film layer and the second PE film layer material is 200°C, the melt temperature of the first adhesive film layer and the second adhesive film layer material is 225°C, and the first The melt temperature of the material of the PA film layer and the second PA film layer is 255°C, and the melt temperature of the material of the intermediate EVOH film layer is 225...

Embodiment 2

[0031] Add the materials of the first PE film layer, the first adhesive film layer, the first PA film layer, the middle EVOH film layer, the second PA film layer, the second adhesive film layer and the second PE film layer to the seven-layer Melting in the barrel of a co-extrusion blown film machine, blowing the film after co-extrusion, cooling and shaping to obtain the nylon EVOH high barrier film;

[0032] Wherein the mass ratio of metallocene polyethylene, linear polyethylene and high-pressure polyethylene in the first PE film layer and the second PE film layer is 55:20:25;

[0033] The melt temperature of the first PE film layer and the second PE film layer material is 200°C, the melt temperature of the first adhesive film layer and the second adhesive film layer material is 225°C, and the first The melt temperature of the material of the PA film layer and the second PA film layer is 255°C, and the melt temperature of the material of the middle EVOH film layer is 225°C. T...

Embodiment 3

[0036] Add the materials of the first PE film layer, the first adhesive film layer, the first PA film layer, the middle EVOH film layer, the second PA film layer, the second adhesive film layer and the second PE film layer to the seven-layer Melting in the barrel of a co-extrusion blown film machine, blowing the film after co-extrusion, cooling and shaping to obtain the nylon EVOH high barrier film;

[0037] Wherein the mass ratio of metallocene polyethylene, linear polyethylene and high-pressure polyethylene in the first PE film layer and the second PE film layer is 50:25:20;

[0038] The melt temperature of the first PE film layer and the second PE film layer material is 200°C, the melt temperature of the first adhesive film layer and the second adhesive film layer material is 225°C, and the first The melt temperature of the material of the PA film layer and the second PA film layer is 255°C, and the melt temperature of the material of the intermediate EVOH film layer is 225...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com