Coated carbon fiber reinforced ABS/PP electromagnetic shielding composite material and preparation method thereof

A technology of electromagnetic shielding and composite materials, applied in the field of electromagnetic shielding materials, can solve the problems of poor compatibility between fibers and resins, high resistivity of composite materials, and loose bonding, etc., to achieve uniform material mixing, excellent corrosion resistance, and improved bonding ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

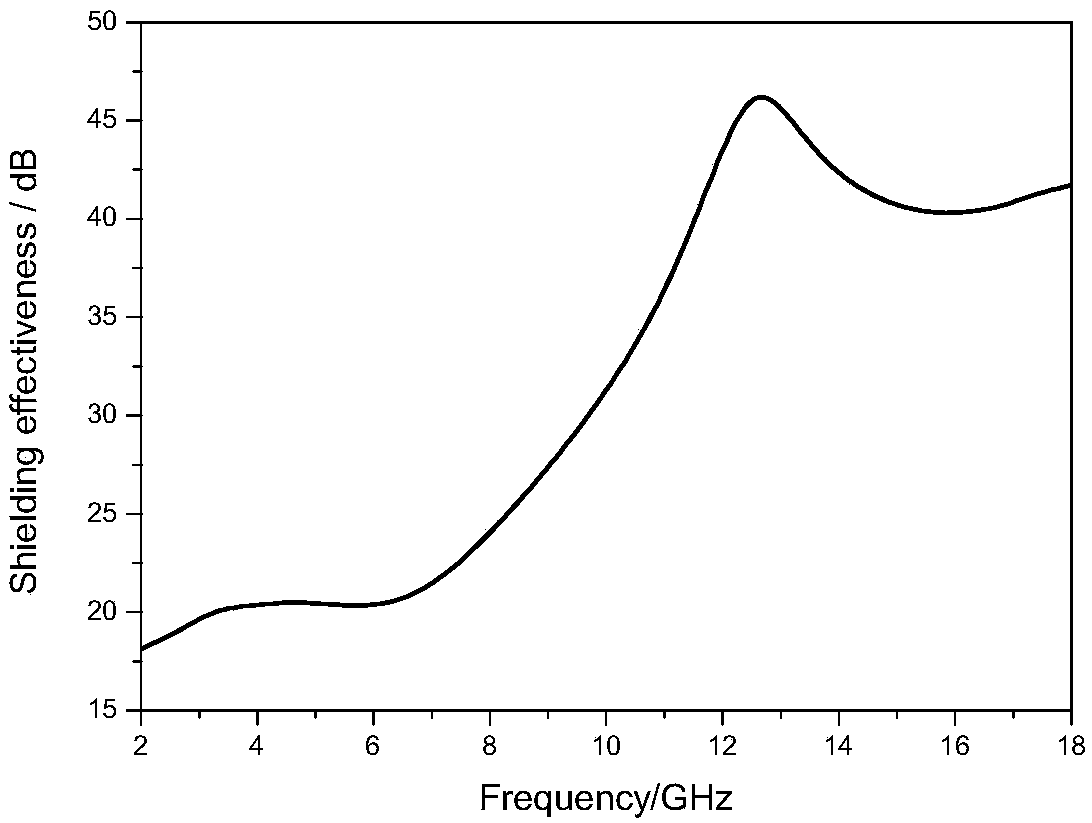

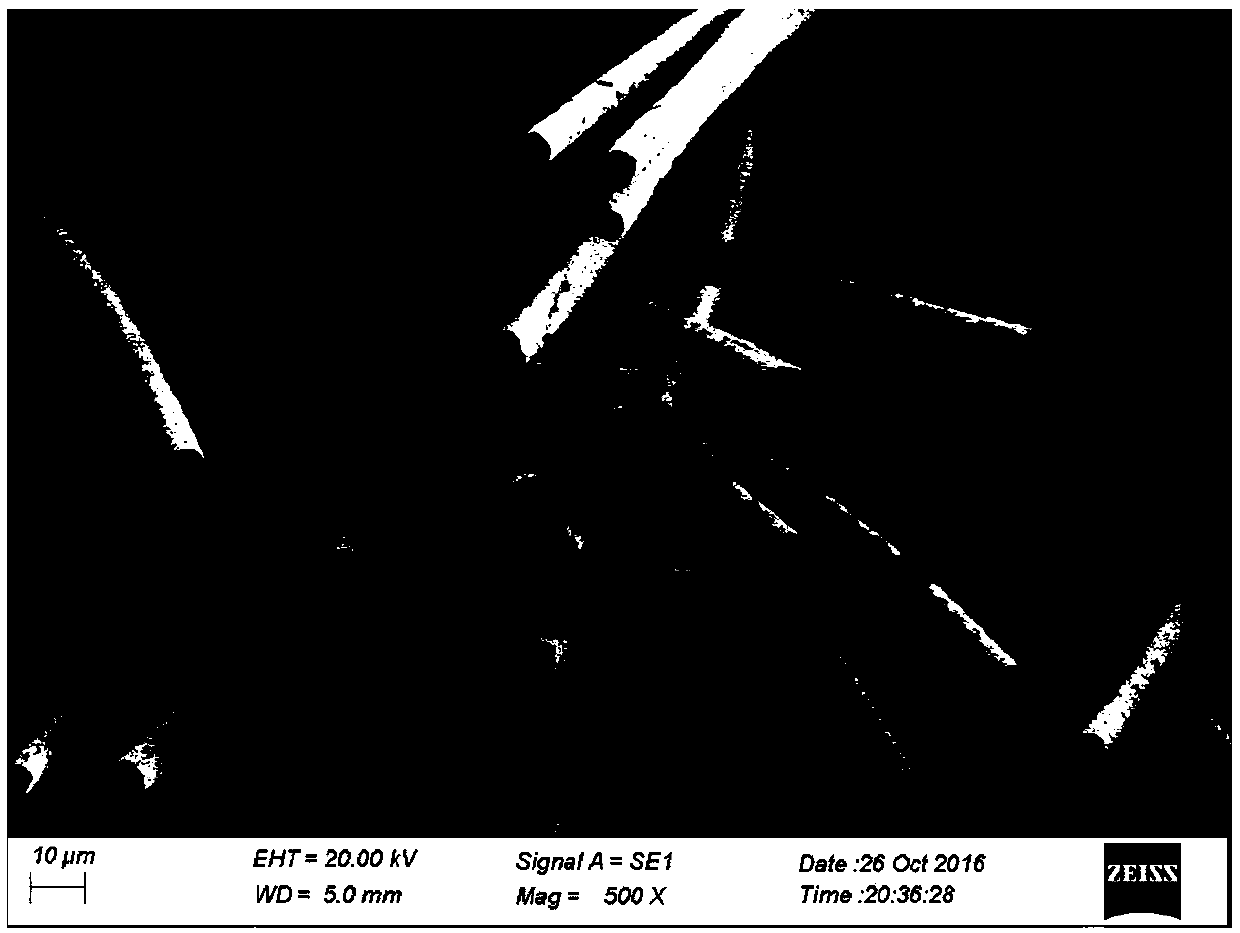

[0038] A preparation method of a coated carbon fiber reinforced ABS / PP electromagnetic shielding composite material according to this embodiment is implemented according to the following steps: 1. Put the carbon fiber in a tube furnace at a temperature of 720°C for 10 minutes; Put the carbon fiber in acetone and ultrasonically clean it for 15 minutes; 3. Prepare the nickel-aluminum coating on the surface of the carbon fiber treated in step 2 by radio frequency magnetron sputtering; 4. Shorten the coated carbon fiber treated in step 3 into a length of 2mm , to obtain chopped coated carbon fibers; 5. ABS resin, PP resin, crosslinking agent and coupling agent are placed in a high mixer in a ratio of 20:57:0.2:3, and mixed at a speed of 900r / min for 10 Minutes, make the premix; 6, place the carbon fiber after the step 4 treatment and the premix after the step 5 treatment in the ratio of 20:80 respectively in the side feeding port and the main feeding port of the twin-screw extruder...

Embodiment 2

[0042] A preparation method of a coated carbon fiber reinforced ABS / PP electromagnetic shielding composite material according to this embodiment is implemented according to the following steps: 1. Put the carbon fiber in a tube furnace at a temperature of 720°C for 10 minutes; Put the carbon fiber in acetone and ultrasonically clean it for 15 minutes; 3. Prepare the nickel-iron coating on the surface of the carbon fiber treated in step 2 by DC magnetron sputtering; 4. Shorten the coated carbon fiber treated in step 3 into a length of 5 mm , to obtain chopped coated carbon fibers; 5. ABS resin, PP resin, crosslinking agent and coupling agent are placed in a high mixer in a ratio of 30:33:0.1:2, and mixed at a speed of 900r / min for 10 Minutes, make the premix; 6, place the carbon fiber after the step 4 treatment and the premix after the step 5 treatment in the ratio of 35:65 respectively in the side feeding port and the main feeding port of the twin-screw extruder, melt Extrusio...

Embodiment 3

[0046] A preparation method of a coated carbon fiber reinforced ABS / PP electromagnetic shielding composite material according to this embodiment is implemented according to the following steps: 1. Put the carbon fiber in a tube furnace at a temperature of 720°C for 10 minutes; Put the carbon fiber in acetone and ultrasonically clean it for 15 minutes; 3. Prepare a nickel-copper coating on the surface of the carbon fiber treated in step 2 by DC magnetron sputtering; 4. Shorten the coated carbon fiber treated in step 3 into a length of 8 mm , to obtain chopped coated carbon fibers; 5. ABS resin, PP resin, crosslinking agent and coupling agent are placed in a high mixer in a ratio of 30:57:0.2:3, and mixed at a speed of 900r / min for 10 Minutes to make a premix; 6. Place the carbon fiber processed in step 4 and the premix processed in step 5 in the ratio of 10:90 respectively in the side feed port and the main feed port of the twin-screw extruder, and melt Extrusion, that is to co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com