Nitrogen/sulfur-doped three-dimensional carbon nano-network supporting molybdenum disulfide nano-material and preparation of the nano-material

A molybdenum disulfide, network loading technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of unfavorable catalytic performance, poor conductivity of MoS2, etc., and achieve the effects of excellent morphology, good performance and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

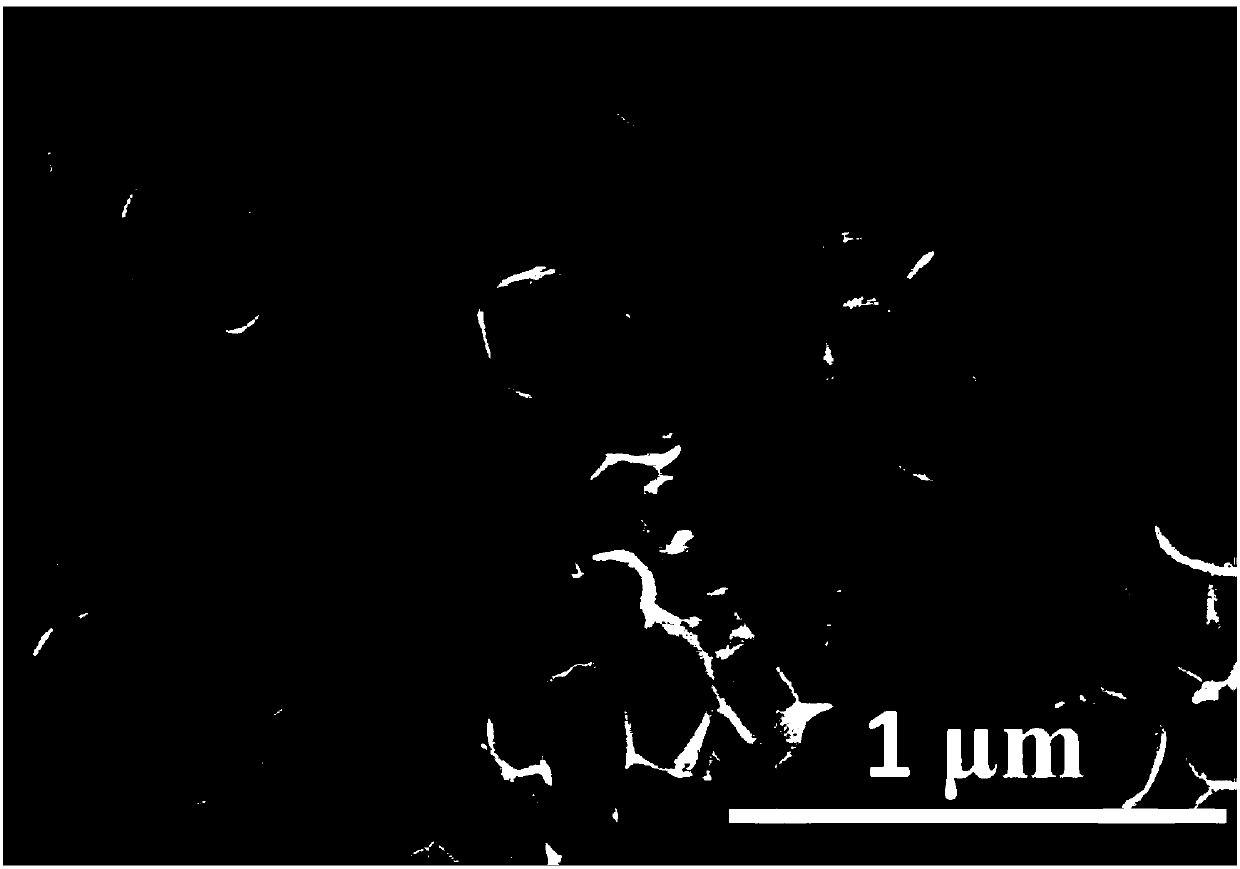

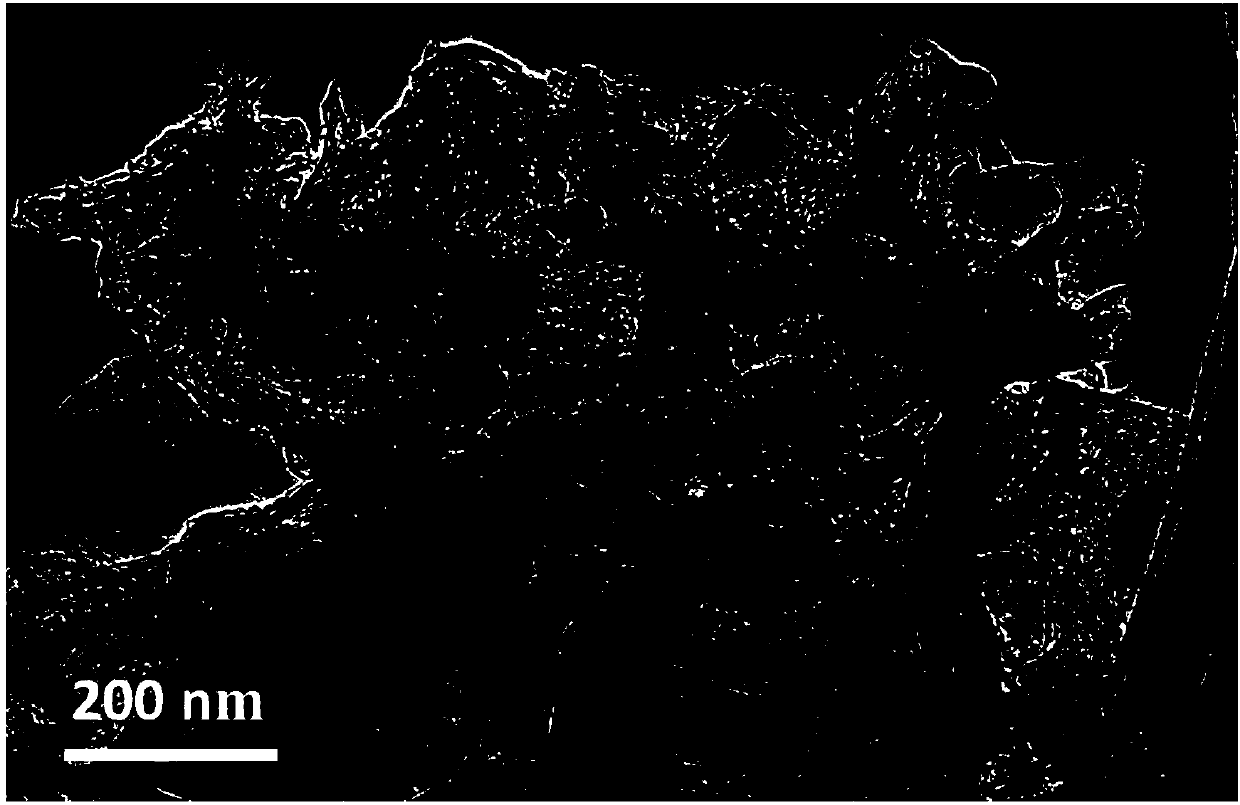

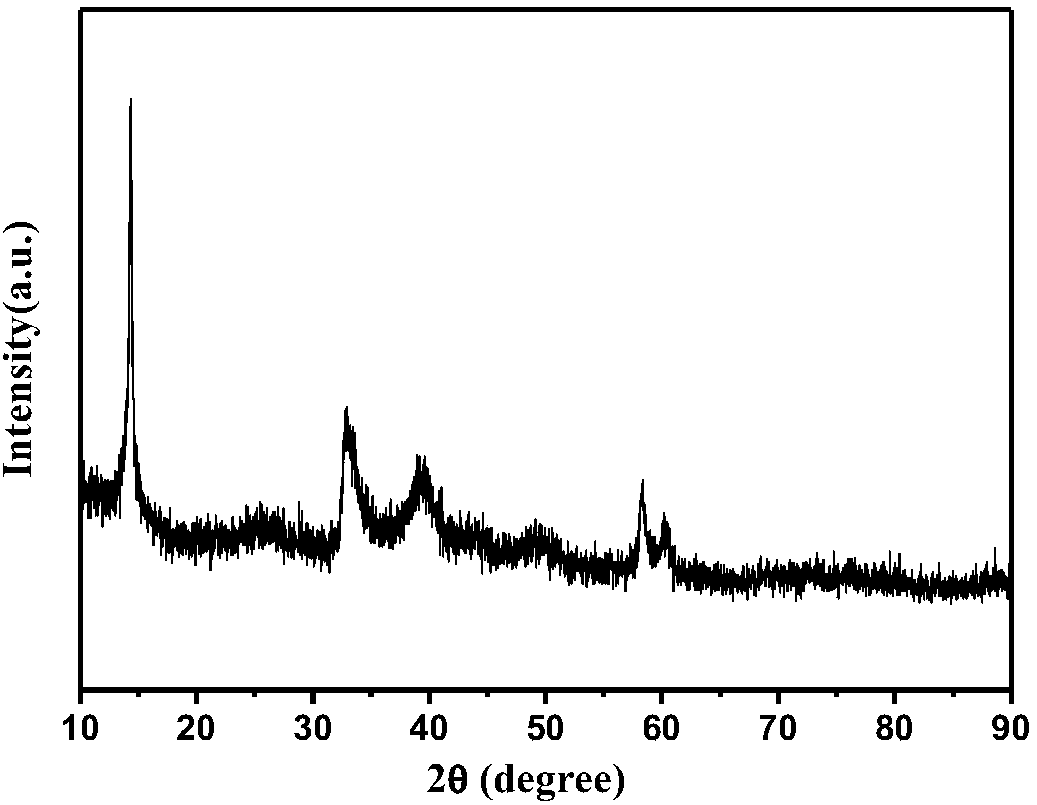

[0018] Weigh 3.8g citric acid, 0.24g melamine, 0.25g ammonium paramolybdate tetrahydrate and 2.8g Na 2 SO 4 , dissolve the mixture in 50ml of deionized water, stir and dissolve with a magnetic stirrer at a stirring speed of 300r / min to form a solution, then use an ultrasonic device with a power of 400W for 15min, mix evenly and place in a freezer to freeze until the solution is completely After freezing, it was placed in a freeze dryer at -50°C for vacuum drying to obtain a mixture. Grind the mixture, take 10g of the mixed powder and place it in the ark, put the ark into the tube furnace, pass in 200ml / min Ar inert gas for 30min to remove the air, then use 200ml / min Ar as the carrier gas, and set the temperature at 10°C The temperature was raised to 750°C at a heating rate of 1 / min, and the carbonization reaction was carried out at a heat preservation time of 2 hours. After the reaction was completed, it was cooled to room temperature under the protection of an Ar atmosphere ...

Embodiment 2

[0021] Weigh 3.8g citric acid, 0.24g melamine, 0.25g ammonium paramolybdate tetrahydrate and 2.8g Na 2 SO 4 , dissolve the mixture in 50ml of deionized water, stir and dissolve with a magnetic stirrer at a stirring speed of 300r / min to form a solution, then use an ultrasonic device with a power of 400W for 15min, mix evenly and place in a freezer to freeze until the solution is completely After freezing, it was placed in a freeze dryer at -50°C for vacuum drying to obtain a mixture. Grind the mixture, take 10g of the mixed powder and place it in the ark, put the ark into the tube furnace, pass in 200ml / min Ar inert gas for 30min to remove the air, then use 200ml / min Ar as the carrier gas, and set the temperature at 10°C The temperature was raised to 700°C at a heating rate of / min, and the carbonization reaction was carried out at a heat preservation time of 2 hours. After the reaction was completed, it was cooled to room temperature under the protection of an Ar atmosphere t...

Embodiment 3

[0023] Weigh 3.8g citric acid, 0.24g melamine, 0.5g ammonium paramolybdate tetrahydrate and 2.8g Na 2 SO 4 , dissolve the mixture in 50ml of deionized water, stir and dissolve with a magnetic stirrer at a stirring speed of 300r / min to form a solution, then use an ultrasonic device with a power of 400W for 15min, mix evenly and place in a freezer to freeze until the solution is completely After freezing, it was placed in a freeze dryer at -50°C for vacuum drying to obtain a mixture. Grind the mixture, take 10g of the mixed powder and place it in the ark, put the ark into the tube furnace, pass in 200ml / min Ar inert gas for 30min to remove the air, then use 200ml / min Ar as the carrier gas, and set the temperature at 10°C The temperature was raised to 750°C at a heating rate of 1 / min, and the carbonization reaction was carried out at a heat preservation time of 2 hours. After the reaction was completed, it was cooled to room temperature under the protection of an Ar atmosphere t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com