Slump resisting and water reducing type polycarboxylic acid slump resisting agent and preparation method thereof

A technology of polycarboxylic acid and water-reducing type, which is applied in the field of slump-retaining water-reducing polycarboxylate slump-retaining agent and its preparation, which can solve the problems of production temperature exceeding 100°C and large energy consumption, and achieve low production temperature and high process efficiency. The effect of low requirements and convenient mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

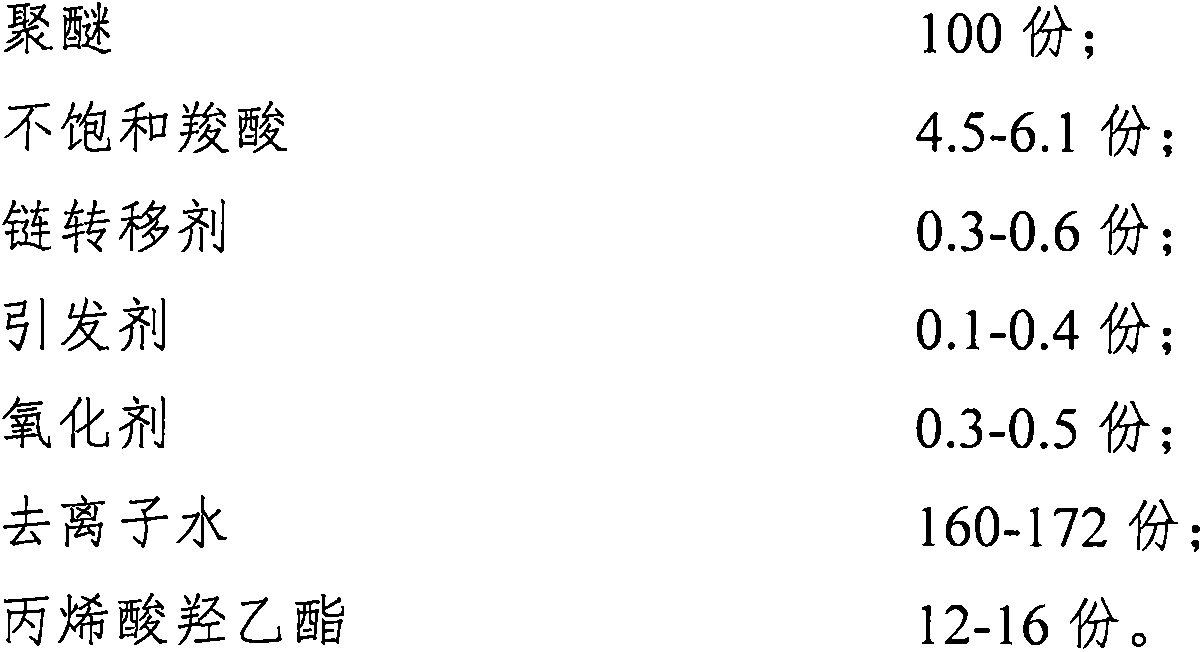

[0011] The slump-retaining and water-reducing polycarboxylic acid slump-preserving agent of this embodiment includes the following raw materials by weight:

[0012]

[0013] Preferably, the initiator is one or a mixture of antiseptic acid, citric acid, and oxalic acid.

[0014] Preferably, the molecular formula of the polyether is CH 2 =C(CH 3 )CH 2 CH 2 O(CH 2 CH 2 O)nCH 3 , Where n is a positive integer.

[0015] Preferably, the chain transfer agent is one or a mixture of thioglycolic acid, aliphatic mercaptan, and dodecyl mercaptan.

[0016] Preferably, the oxidant is one or a mixture of one or more of peracetic acid, performic acid, and hydrogen peroxide.

[0017] The preparation method of the slump-retaining and water-reducing polycarboxylic acid slump-retaining agent of this embodiment includes:

[0018] Step 1: Mix 4.5 parts of unsaturated carboxylic acid and 12 parts of hydroxyethyl acrylate plus 32 parts of deionized water for 15 minutes to prepare solution A;

[0019] Step 2: Ad...

Embodiment 2

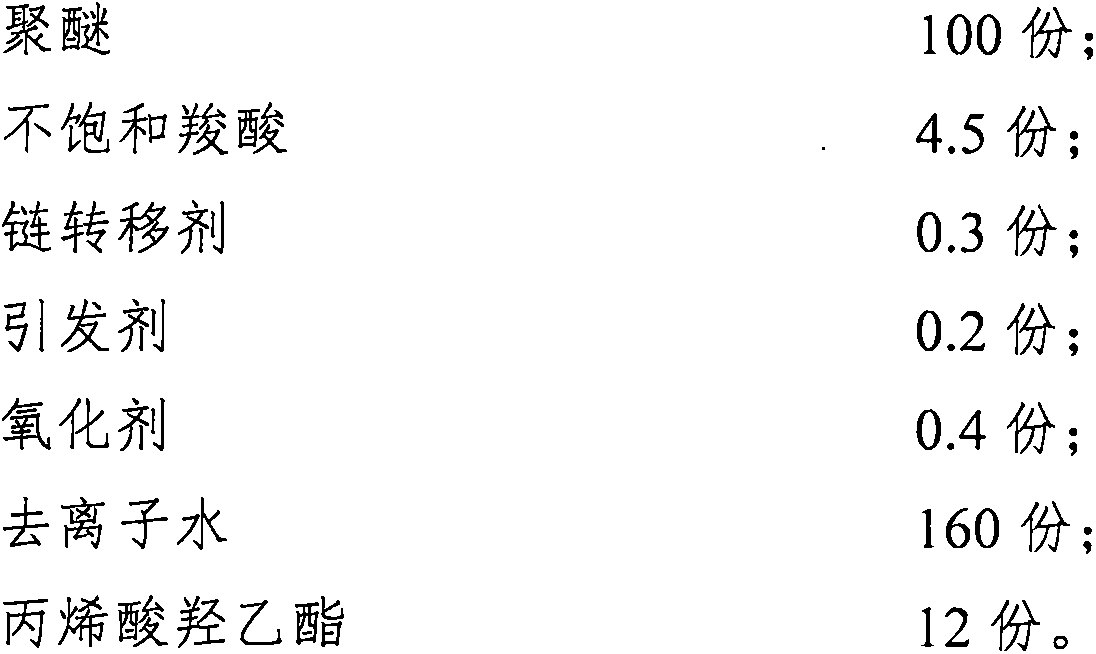

[0024] The slump-retaining and water-reducing polycarboxylic acid slump-preserving agent of this embodiment includes the following raw materials by weight:

[0025]

[0026] The preparation method of the slump-retaining and water-reducing polycarboxylic acid slump-retaining agent of this embodiment includes:

[0027] Step one, stir 5.0 parts of unsaturated carboxylic acid and 13 parts of hydroxyethyl acrylate plus 32 parts of deionized water for 15 minutes to prepare solution A;

[0028] Step 2: Add 0.4 parts of initiator to 32 parts of deionized water and 0.5 parts of chain transfer agent configuration solution B;

[0029] Step 3: Keep 96 parts of deionized water at (40±2)℃, add 100 parts of polyether, stir to dissolve, add 0.3 part of oxidant after 20 minutes, add solution A and solution B dropwise after 5 minutes, control the dropping time It is about 210 minutes and 180 minutes respectively;

[0030] Step 4. After dripping, keep it warm for 90 minutes;

[0031] Step 5: After the hea...

Embodiment 3

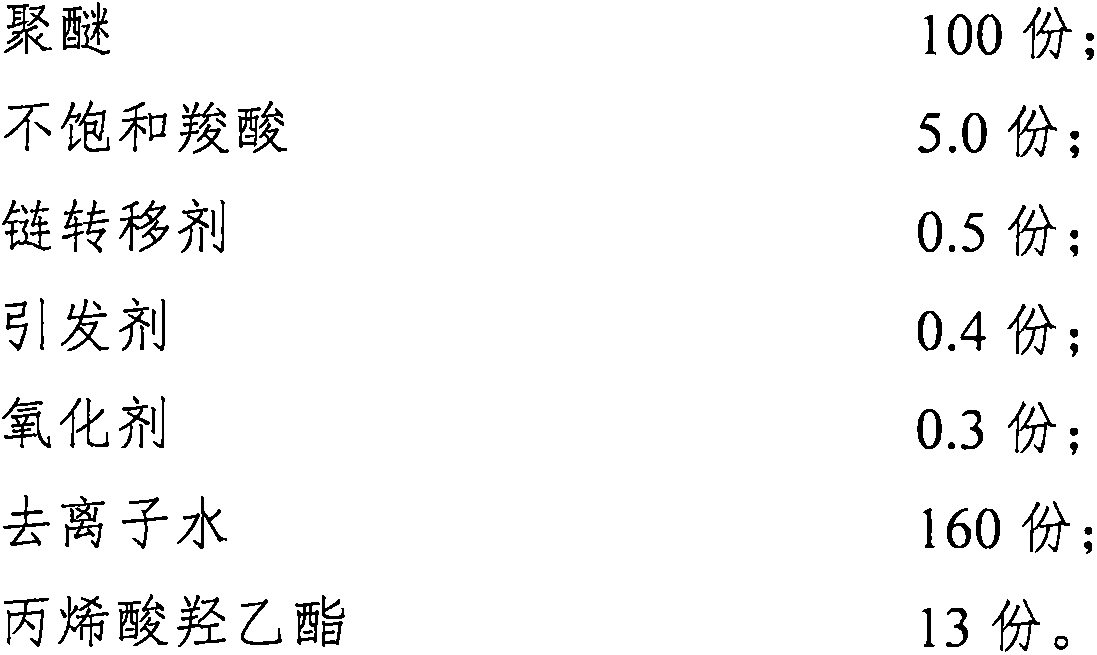

[0033] The slump-retaining and water-reducing polycarboxylic acid slump-preserving agent of this embodiment includes the following raw materials by weight:

[0034]

[0035] The preparation method of the slump-retaining and water-reducing polycarboxylic acid slump-retaining agent of this embodiment includes:

[0036] Step one, stir 5.5 parts of unsaturated carboxylic acid and 14 parts of hydroxyethyl acrylate plus 33 parts of deionized water for 15 minutes to prepare solution A;

[0037] Step 2: Add 0.3 parts of initiator to 33 parts of deionized water and 0.4 parts of chain transfer agent configuration solution B;

[0038] Step 3: Keep 99 parts of deionized water at (40±2)℃, add 100 parts of polyether, stir to dissolve, add 0.5 part of oxidant after 20 minutes, add solution A and solution B dropwise after 5 minutes, control the dropping time It is about 210 minutes and 180 minutes respectively;

[0039] Step 4. After dripping, keep it warm for 90 minutes;

[0040] Step 5: After the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com