Preparation method of anti-static bacteriostatic polyester staple fiber

A polyester staple fiber, antistatic technology, applied in conductive/antistatic filament manufacturing, fiber chemical characteristics, rayon manufacturing and other directions, can solve the problems of poor antibacterial and antistatic properties of polyester fibers, and reduce static electricity effects. , The effect of increasing the specific surface area and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

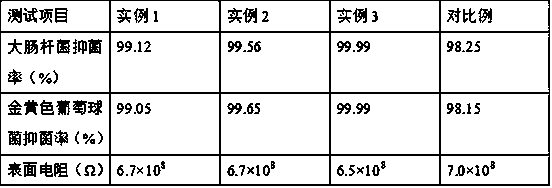

Examples

example 1

[0028] Take 100g of mulberry bark and soak it in 400mL of sulfuric acid solution with a mass fraction of 30%. , heat up to 90°C, add 100mL sodium hydroxide solution with a mass fraction of 40%, 50mL sodium polyphosphate solution with a mass fraction of 4%, and 30mL sodium silicate solution with a mass fraction of 6% into the water bath. After cooking for 2 hours, filter and remove the filtrate to obtain alkali-boiled mulberry bark; soak the above-mentioned alkali-boiled mulberry bark with 150 mL of hydrochloric acid with a mass fraction of 10% for 8 min, take out the soaked mulberry bark, beat it with a wooden hammer and rinse with water, and place in In an oven, heat up to 100°C and dry for 10 hours to obtain mulberry fibers; put bamboo chips in a muffle furnace, remove the air in the muffle furnace, heat up to 1000°C, and burn for 3 hours to obtain bamboo charcoal. Pulverize with a jet mill to obtain an activated carbon powder with a particle size of 400nm, mix the masterbat...

example 2

[0030] Take 110g of mulberry bark and soak it in 420mL sulfuric acid solution with a mass fraction of 30%. In the pot, heat up to 95°C, add 110mL of sodium hydroxide solution with a mass fraction of 40%, 55mL of a sodium polyphosphate solution with a mass fraction of 4%, and 35mL of a sodium silicate solution with a mass fraction of 6% , after cooking for 2.5h, filter, remove the filtrate to obtain the alkali-boiled mulberry bark; soak the above-mentioned alkali-boiled mulberry bark with 170mL of 10% hydrochloric acid for 9min, take out the soaked mulberry bark and beat it with a wooden hammer and rinse it with water. Place in an oven, heat up to 105°C, and dry for 11 hours to obtain mulberry fibers; place bamboo chips in a muffle furnace, pump out the air in the muffle furnace, heat up to 1050°C, and burn for 3.5 hours to obtain bamboo charcoal , bamboo charcoal is pulverized with an airflow mill to obtain activated carbon powder with a particle size of 450nm, and the masterb...

example 3

[0032] Take 120g of mulberry bark and soak it in 450mL sulfuric acid solution with a mass fraction of 30%. , heat up to 100°C, add 120mL sodium hydroxide solution with a mass fraction of 40%, 60mL sodium polyphosphate solution with a mass fraction of 4%, and 40mL sodium silicate solution with a mass fraction of 6% into the water bath. After cooking for 3 hours, filter and remove the filtrate to obtain alkali-boiled mulberry bark; soak the above-mentioned alkali-boiled mulberry bark with 180 mL of hydrochloric acid with a mass fraction of 10% for 10 min, take out the soaked mulberry bark, beat it with a wooden hammer and rinse it with water, and place it in In an oven, heat up to 110°C and dry for 12 hours to obtain mulberry fibers; put bamboo chips in a muffle furnace, remove the air in the muffle furnace, heat up to 1100°C, and burn for 4 hours to obtain bamboo charcoal. Pulverize with a jet mill to obtain an activated carbon powder with a particle size of 500nm, mix the mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com