Multi-nano carbon filament composite carbon fiber and preparation method thereof

A technology of composite carbon fiber and nano-carbon, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of good synthesis process and lack of reproducibility, and achieve the effect of simple and easy preparation process and large pitch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

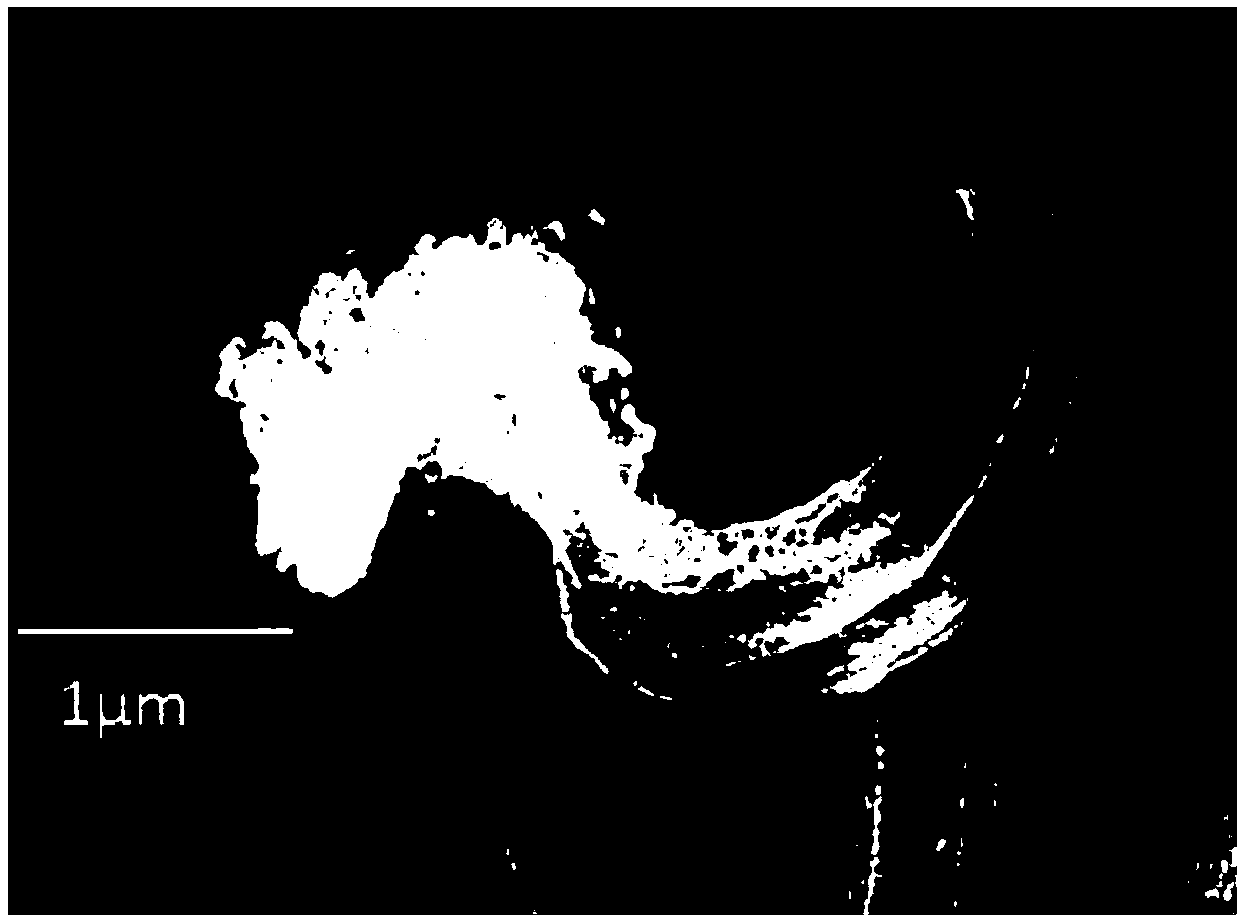

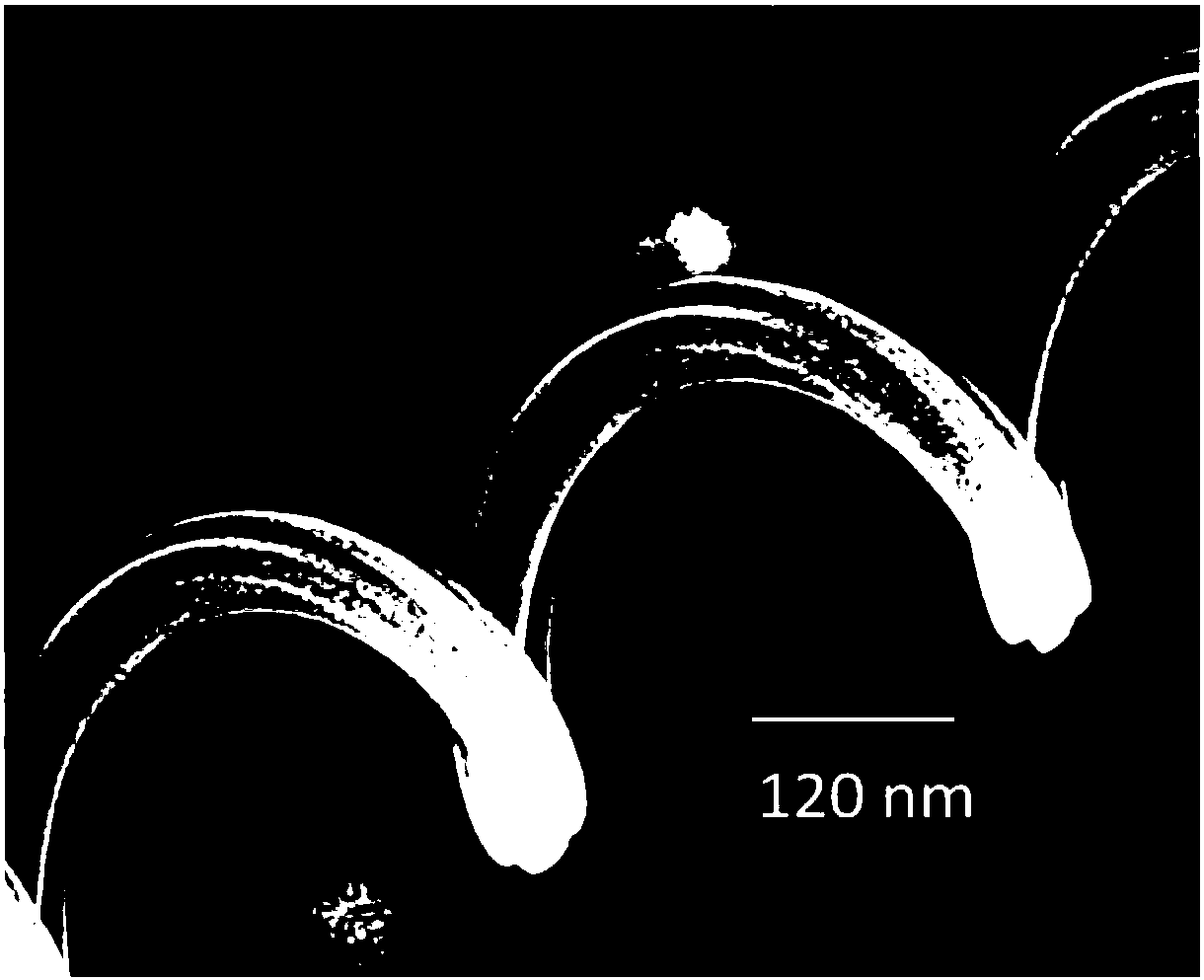

[0049] Synthesis Example 1: The supported catalyst is pressed at 30 mg / cm 2 The amount of acetylene is tiled on the surface of the substrate placed in the reactor. The reactor is kept at a constant temperature of 700-750°C under a nitrogen atmosphere. The flow rate of acetylene introduced is 1 sccm per square centimeter of the substrate area. 1.5:1, the ratio of the amount of nitrogen and hydrogen introduced is 0.5:1, and at the same time, hydrogen is used to carry the sulfur-containing substance thiophene into the reaction system, and the sulfur content in the gas is controlled to account for 0.5%, so that hydrocarbons are catalytically cracked under hydrogen atmosphere The carbon-forming particles are deposited on the crystal surface of the composite catalyst, and react for two hours to obtain a spiral-shaped carbon fiber composed of multiple nano-carbon filaments. Its microscopic shape is as follows: figure 1 with figure 2 As shown, the measured rigidity rate is 10.7Gpa. ...

Embodiment 2

[0050] Synthetic embodiment two: the supported catalyst is pressed 50mg / cm 2 The amount of acetylene is tiled on the surface of the substrate placed in the reactor. The reactor is kept at a constant temperature of 760-790°C under a nitrogen atmosphere. The flow rate of acetylene introduced is 5 sccm per square centimeter of substrate area. 2:1, the ratio of the amount of nitrogen and hydrogen introduced is 3:1, and at the same time, the hydrogen gas is used to carry the sulfur-containing substance thiophene into the reaction system, and the sulfur content in the gas is controlled to account for 0.9%, so that the hydrocarbons are in the hydrogen atmosphere. Catalytic cracking into carbon particles deposited on the crystal surface of the composite catalyst, reacting for two hours to obtain a spiral carbon fiber composited by multiple nano-carbon filaments, the diameter of the spiral is 4.2 μm, the pitch is 1.2 μm, and the measured rigidity rate is 10.3 Gpa.

Embodiment 3

[0051] Synthetic Example three: the supported catalyst is pressed at 10mg / cm 2 The amount of acetylene is tiled on the surface of the substrate placed in the reactor. The reactor is kept at a constant temperature of 800-850°C under a nitrogen atmosphere, and gaseous hydrocarbons and hydrogen are introduced. The ratio of the amount of hydrocarbons introduced is 0.5:1, the ratio of the amount of nitrogen and hydrogen introduced is 0.5:1, and the hydrogen is used to carry the sulfur-containing substance thiophene into the reaction system, and the sulfur content in the control gas accounts for 0.1%. , the hydrocarbons are catalytically cracked into carbon particles in a hydrogen atmosphere and deposited on the crystal surface of the composite catalyst, and react for two hours to obtain a spiral-shaped carbon fiber composited by multiple nano-carbon filaments, with a spiral diameter of 1.9 μm and a pitch of 0.5 μm , the measured rigidity rate is 11.7Gpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com