Dual-wavelength phase-shift interference aspheric surface measurement method and device based on partial compensation method

A technology of phase-shift interference and measurement method, which is applied in the field of high-precision measurement of optical aspheric surface error, can solve the problems of increasing the difficulty and cycle of instrument design, shorten the cycle of instrument design, reduce the difficulty and cost of system design, and achieve high The effect of precision reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

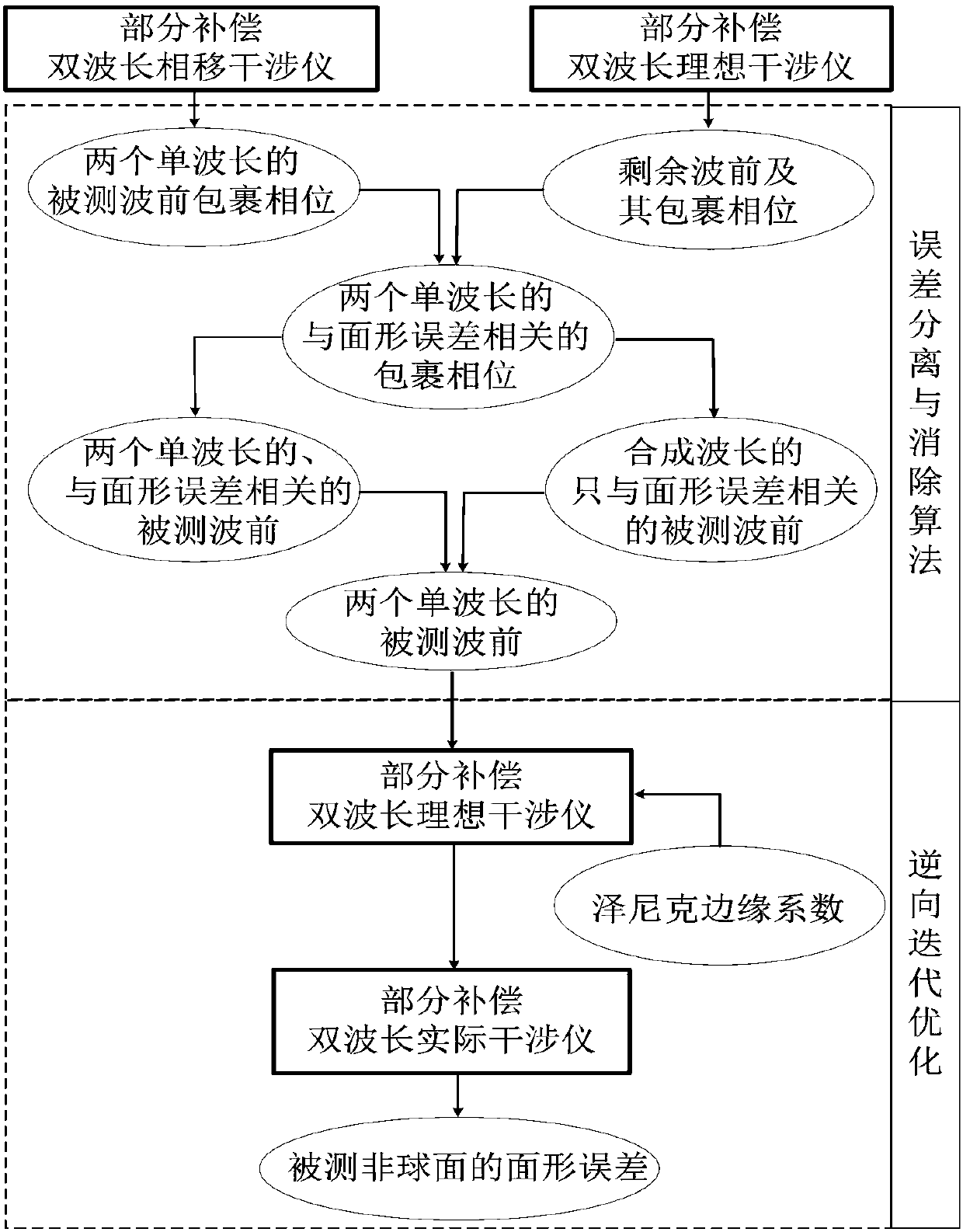

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: Large asphericity ellipsoid measurement.

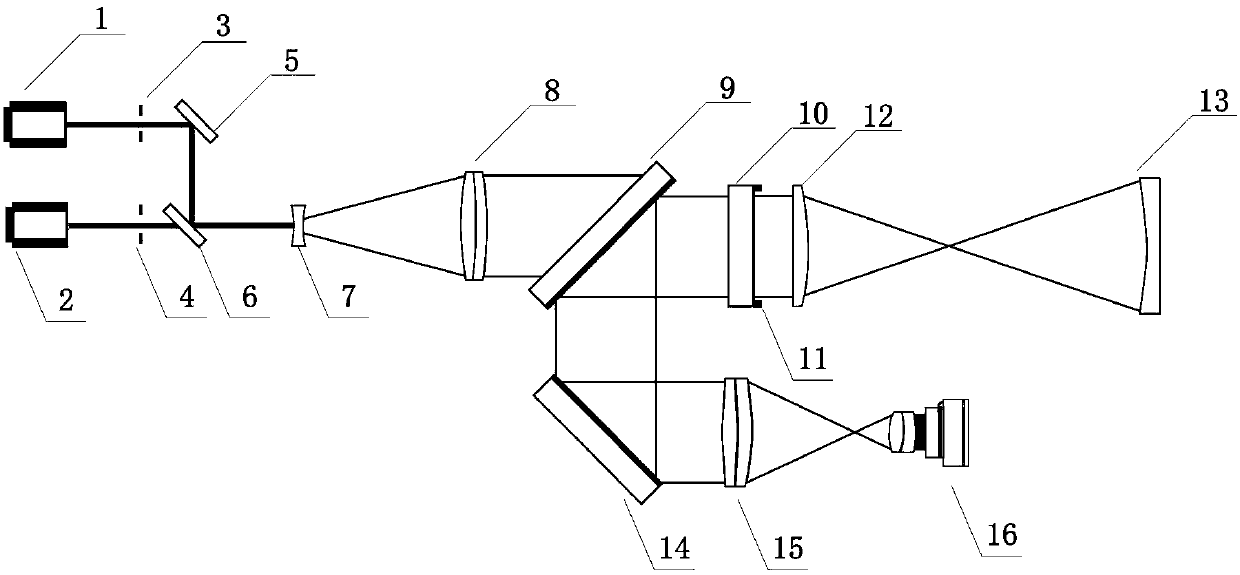

[0065] The implementation device of this embodiment is as figure 2 As shown, the working wavelength λ output by the first laser (1) and the second laser (2) 1 and lambda 2 532nm and 556nm respectively, resulting in an equivalent synthetic wavelength λ eq is 12.325μm, and the maximum measurable difference between adjacent optical path differences is 6.162μm.

[0066] In the present embodiment, the light aperture D of the measured ellipsoid (13) is 580 mm, and the radius of curvature R of the aspheric surface vertex 0 It is -1179.447mm, and the relative diameter of the aspheric surface is D / R 0 is 1 / 2, the maximum asphericity of the measured ellipsoid relative to the vertex sphere and the best reference sphere is 281.85 μm and 67.80 μm respectively, which is an aspheric surface with a relatively large asphericity. The addition of small facet errors to the ellipsoid creates a steep wavefront.

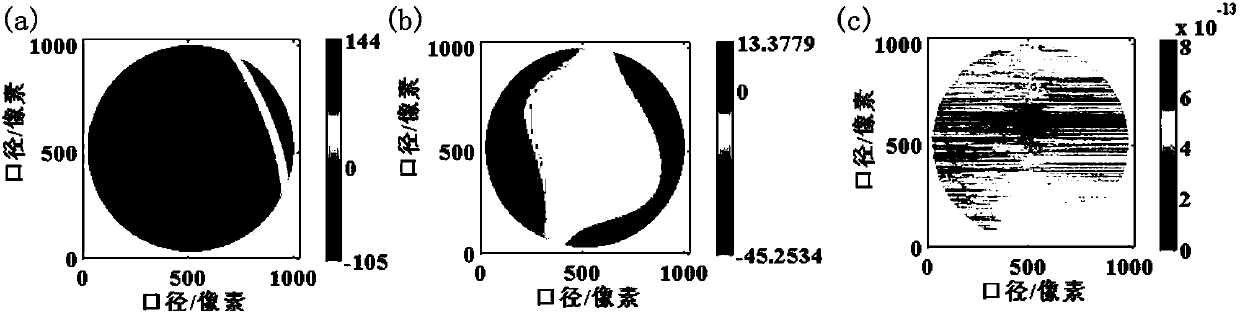

[0067] The glas...

Embodiment 2

[0079] Embodiment 2: Large surface error paraboloid measurement.

[0080] In this embodiment, the measured aspheric surface (13) is a paraboloid with a large surface shape error, its light aperture D is 108mm, and its apex curvature radius R 0 It is -1727.2mm, and the relative diameter of the paraboloid is D / R 0 It is 1 / 16, and the maximum asphericity of the measured paraboloid relative to the vertex sphere and the best reference sphere is 0.206μm and 0.052μm respectively, which is a shallow aspheric surface.

[0081] The glass material of the designed partial compensating mirror (12) for compensating the paraboloid is K9, and the radius of curvature r of the front and rear surfaces 1 and r 2 They are 760mm and -4965mm respectively, and are also a simple biconvex lens. The thickness of the partial compensation mirror (12) is 20mm, and the distance between the partial compensation mirror (12) and the measured aspheric surface (13) is 2985mm.

[0082] Using the method propose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Clear aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Clear aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com