Adsorption extraction separation and purification method

An extraction and extraction agent technology, applied in the field of chemical separation, purification and purification, can solve the problems of low yield of oxygenated compounds, low regeneration efficiency, low adsorption efficiency, etc., and achieve the effect of solving the extremely difficult choice of desorption process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

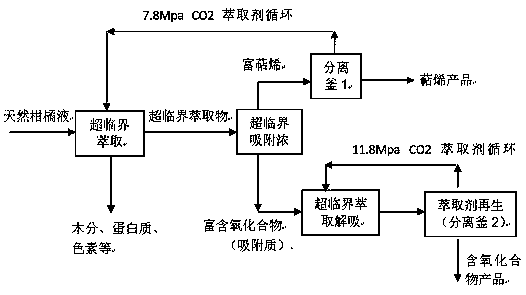

[0054] Such as figure 1 As shown, a method of adsorption, extraction, separation and purification is applied to the preparation of ultra-pure ammonia (99.99999% pure) by deep dehydration, impurity removal and purification using liquid ammonia as a raw material, including the following steps:

[0055] (1) Liquid phase adsorption process, liquid ammonia with a purity of 99.999% (v / v, 5N grade, the same below) is used as the raw material liquid, at a temperature of -10~10°C, 1.0~2.0MPa, enters a The adsorption tower performs liquid phase adsorption at an adsorption temperature of -10~10°C and an adsorption pressure of 1.0~2.0MPa. A small amount of water is used as an adsorbate, which is adsorbed by a type A or 13X molecular sieve adsorbent packed in the adsorption tower. After the adsorption is saturated, enter the next step, the extraction and desorption process; the ammonia and a small amount of low-boiling impurity components are not adsorbed, but flow out from the bottom of t...

Embodiment 2

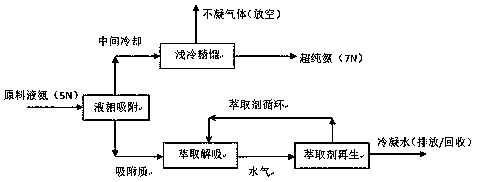

[0061] Such as figure 2 As shown, a method of adsorption, extraction, separation and purification is applied to the simultaneous recovery of H2 and C2+ in refinery dry gas, in which C2+ (carbon 2 and above components) is the adsorbate, and H2 (hydrogen) is the non-adsorbing phase group Divide, present embodiment is made of following operation:

[0062] (1) C2+ adsorption concentration process, temperature is 50~60℃, pressure is 3.0~4.0MPa, H2 content is 35% (V / V, the same below), C2+ content is 16%, methane is 38%, other inert components The 11% refinery dry gas directly enters the C2+ adsorption and concentration system through the intake pipe without cooling or pressurization, and adopts a 2-tower parallel process at an operating temperature of 50~60°C and an operating pressure of 3.0~4.0MPa. Adsorption, one adsorption tower performs medium-temperature and medium-pressure adsorption, the other adsorption tower performs isothermal and isobaric C2+ extraction and desorption,...

Embodiment 3

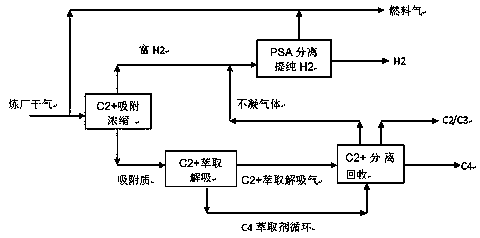

[0068] Such as image 3 As shown, a method of adsorption, extraction, separation and purification is applied to the recovery of olefins from polyolefin tail gas, in which, C2+ (carbon two and above components) olefins are the adsorbate, and N2 (nitrogen) is the non-adsorption phase component. This implementation For example, it consists of the following steps:

[0069] (1) Olefins enrichment process, the composition of polyolefin mixed tail gas as feed gas is as follows, among which, C2+ olefins components include ethylene content of 25.5% (volume ratio, the same below), propylene content of 17.5%, and N2 content of 48.2 %, H2 content 8.7%, and a small amount of carbon four / carbon five (C4+) components, the feed gas temperature is 20~40°C, the pressure is 3.0~4.0MPa, and it directly enters one of the adsorption towers composed of two parallel The adsorption tower carries out the adsorption and concentration of olefins, and the adsorption temperature and adsorption pressure ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com