Heat preserving material of solar water heater water tank and preparation method thereof

A technology for solar water heaters and thermal insulation materials, applied in the field of polyurethane thermal insulation materials, can solve the problems of reducing the thermal insulation effect of the water tank, cracking of the foam of the vacuum nozzle, falling off of the foam and the shell, etc., and achieves safe and reliable processing, improved thermal insulation effect, and less addition amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

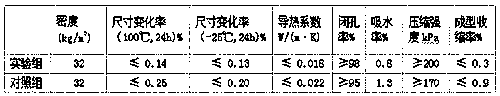

Examples

Embodiment 1

[0023] A thermal insulation material for a water tank of a solar water heater and a preparation method thereof. The material is prepared by mixing and foaming DMI and a polyether polyol composition at a ratio of 1.2:1. The polyether polyol composition includes the following raw materials in parts by weight: 80 parts of glycerol glucoside polyether polyol, 15 parts of water, 6 parts of chitosan, 8 parts of dimethyl phosphate, HFC-356 1 part, N, N-dimethylcyclohexylamine 2 parts and foam stabilizer 1 part.

[0024] The foam stabilizer is silicone with Si-C chain.

[0025] The preparation method of described glycerol glucoside polyether polyol comprises the following steps:

[0026] (1) Add dry starch and propylene glycol into the reactor, add concentrated hydrochloric acid dropwise and mix well;

[0027] (2) Heat the mixture to 130°C and keep it warm for 12 minutes, then the mixture will become a pasty viscous liquid; then continue to react at 130°C for 1 hour, then cool down ...

Embodiment 2

[0036] An insulating material for a water tank of a solar water heater and a preparation method thereof. The material is prepared by mixing and foaming DMI and a polyether polyol composition at a ratio of 1:1. The polyether polyol composition includes the following raw materials in parts by weight: 70 parts of glycerol glucoside polyether polyol, 10 parts of water, 4 parts of chitosan, 6 parts of dimethyl methyl phosphate, HFC-356 0.5 parts, 1 part of N, N-dimethylcyclohexylamine and 0.5 parts of foam stabilizer.

[0037] The foam stabilizer is silicone with Si-C chain.

[0038] The preparation method of described glycerol glucoside polyether polyol comprises the following steps:

[0039] (1) Add dry starch and propylene glycol into the reactor, add concentrated hydrochloric acid dropwise and mix well;

[0040] (2) Heat the mixture to 130°C and keep it warm for 12 minutes, then the mixture will become a pasty viscous liquid; then continue to react at 130°C for 1 hour, then c...

Embodiment 3

[0049] An insulating material for a water tank of a solar water heater and a preparation method thereof. The material is prepared by mixing and foaming DMI and a polyether polyol composition at a ratio of 1.5:1. The polyether polyol composition comprises the following raw materials in parts by weight: 90 parts of glycerol glucoside polyether polyol, 8 parts of water, chitosan, 10 parts of dimethyl phosphate, 2 parts of HFC-356 , 4 parts of N, N-dimethylcyclohexylamine and 2 parts of foam stabilizer.

[0050] The foam stabilizer is silicone with Si-C chain.

[0051] The preparation method of described glycerol glucoside polyether polyol comprises the following steps:

[0052] (1) Add dry starch and propylene glycol into the reactor, add concentrated hydrochloric acid dropwise and mix well;

[0053] (2) Heat the mixture to 130°C and keep it warm for 12 minutes, then the mixture will become a pasty viscous liquid; then continue to react at 130°C for 1 hour, then cool down to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com