Supercapacitor electrode material and preparation method thereof

A technology of supercapacitors and electrode materials, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

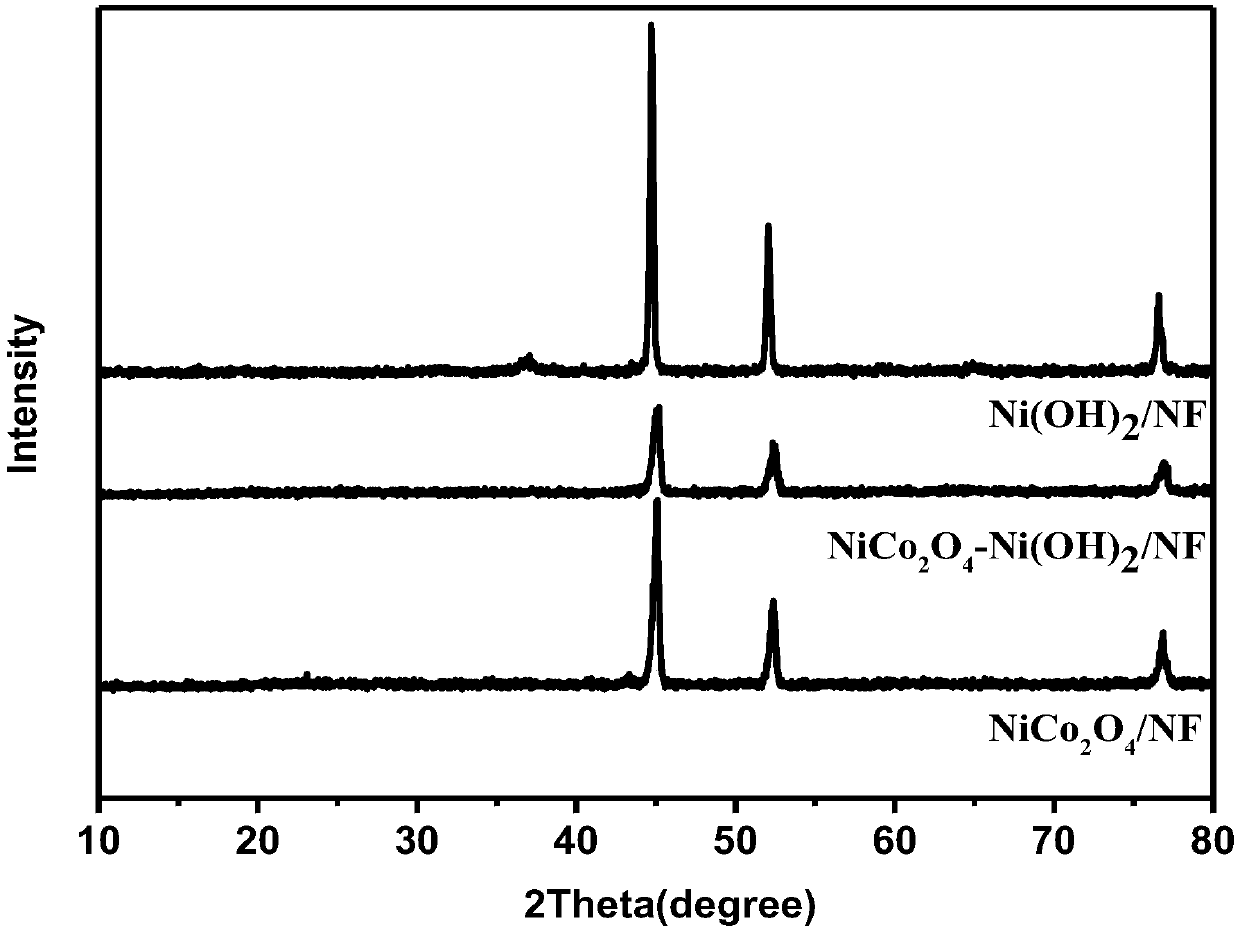

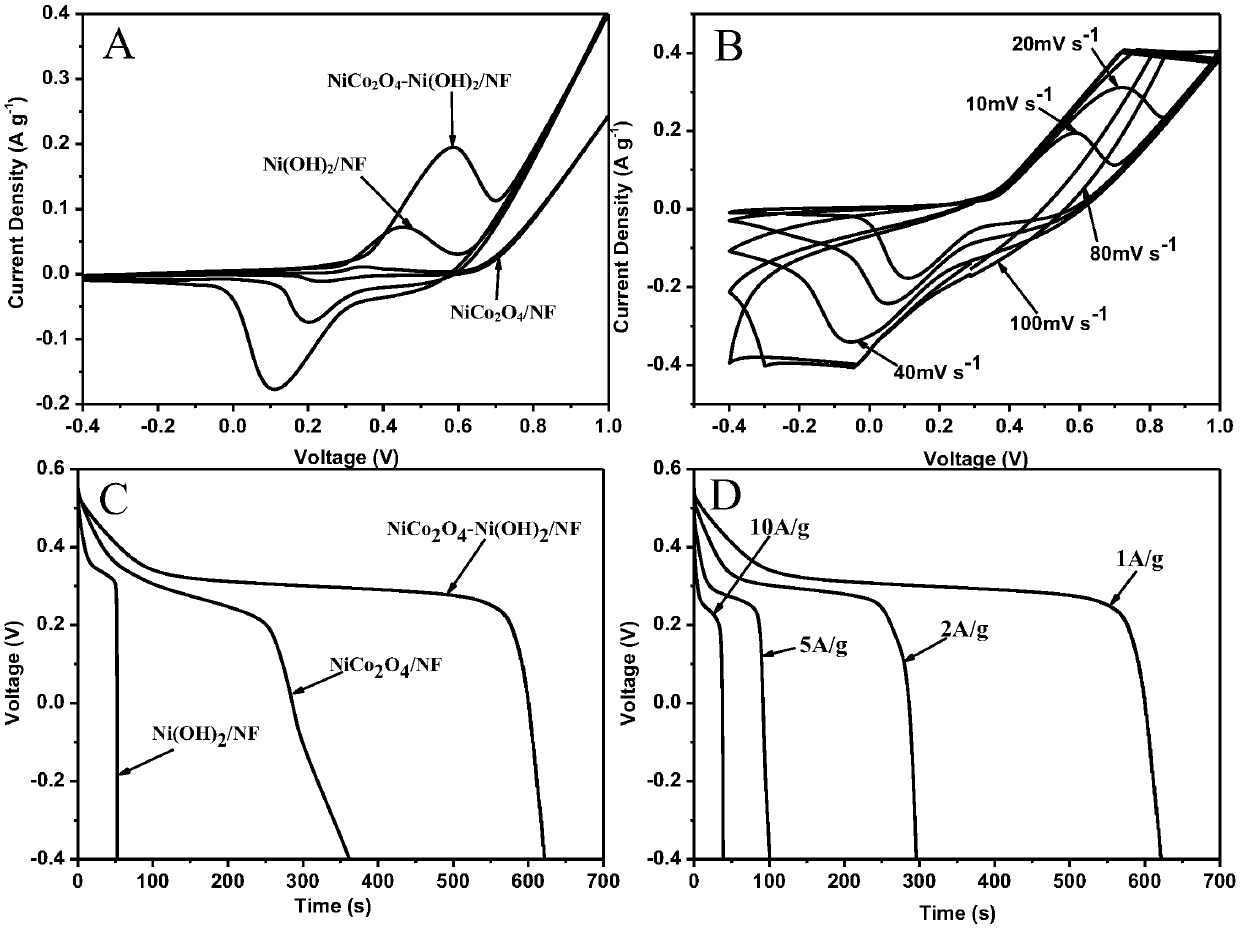

[0028] (1)NiCo 2 o 4 Preparation of / NF samples:

[0029] Weigh 1mmol of Ni(NO 3 ) 2 ·6H 2 O, 2mmol of Co(NO 3 ) 2 ·6H 2 0 and 5 mmol of urea in a beaker, add deionized water to it, magnetically stir until completely dissolved, then add the resulting transparent pink solution to a polytetrafluoroethylene reactor, add pretreated foamed nickel to carry out hydrothermal reaction , 130°C, 5h; after naturally cooling to room temperature, take out the nickel foam, wash it with water and alcohol several times, and dry it to get NiCo 2 o 4 / NF precursor samples. Waiting for NiCo 2 o 4 After the / NF precursor sample was dried, the sample was transferred to a temperature-programmed tube furnace for calcination at 350 °C for 2 h. After cooling down to room temperature naturally, take it out and set aside. Calcined NiCo 2 o 4 The heating rate of the / NF precursor sample was 4 °C / min, and the calcination time was 2 h.

[0030] (2)NiCo 2 o 4 -Ni(OH) 2 / NF composite prepar...

Embodiment 2

[0033] (1)NiCo 2 o 4 Preparation of / NF samples:

[0034] Weigh 2mmol of Ni(NO 3 ) 2 ·6H 2 O, 4mmol of Co(NO 3 ) 2 ·6H 2 O and 10mmol of urea in a beaker, add deionized water to it, magnetically stir until completely dissolved, then add the resulting transparent pink solution to a polytetrafluoroethylene reactor, add pretreated nickel foam for hydrothermal reaction , 130°C, 5h; after naturally cooling to room temperature, take out the nickel foam, wash it with water and alcohol several times, and dry it to get NiCo 2 o 4 / NF precursor samples. Waiting for NiCo 2 o 4 After the / NF precursor sample was dried, the sample was transferred to a temperature-programmed tube furnace for calcination. After cooling down to room temperature naturally, take it out and set aside. Calcined NiCo 2 o 4 The heating rate of the / NF precursor sample was 4 °C / min, the calcination temperature was 350 °C, and the time was 2 h.

[0035] (2)NiCo 2 o 4 -Ni(OH) 2 Preparation of / NF co...

Embodiment 3

[0038] (1)NiCo 2 o 4 Preparation of / NF samples:

[0039] Weigh 4mmol of Ni(NO 3 ) 2 ·6H 2 O, 8mmol of Co(NO 3 ) 2 ·6H 2 0 and 20 mmol of urea in a beaker, add deionized water therein, and magnetically stir until completely dissolved, then add the gained transparent pink solution into a polytetrafluoroethylene reactor, add the prepared nickel foam and carry out hydrothermal reaction for 130 ℃, 5h; after naturally cooling to room temperature, take out the nickel foam, wash it with water and alcohol several times, and dry it to get NiCo 2 o 4 / NF precursor samples. Waiting for NiCo 2 o 4 After the / NF precursor sample was dried, the sample was transferred to a temperature-programmed tube furnace for calcination. After cooling down to room temperature naturally, take it out and set aside. Calcined NiCo 2 o 4 The heating rate of the / NF precursor sample was 4 °C / min, the calcination temperature was 350 °C, and the time was 2 h.

[0040] (2)NiCo 2 o 4 -Ni(OH) 2 P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com