Carbon composite negative electrode material and preparation method thereof

A negative electrode material and composite material technology, applied in the field of lithium-ion battery materials, can solve the problems of low initial efficiency, small tap density, and restrictions on the promotion and use of materials, and achieve high initial efficiency, high tap density, and excellent fast charging performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

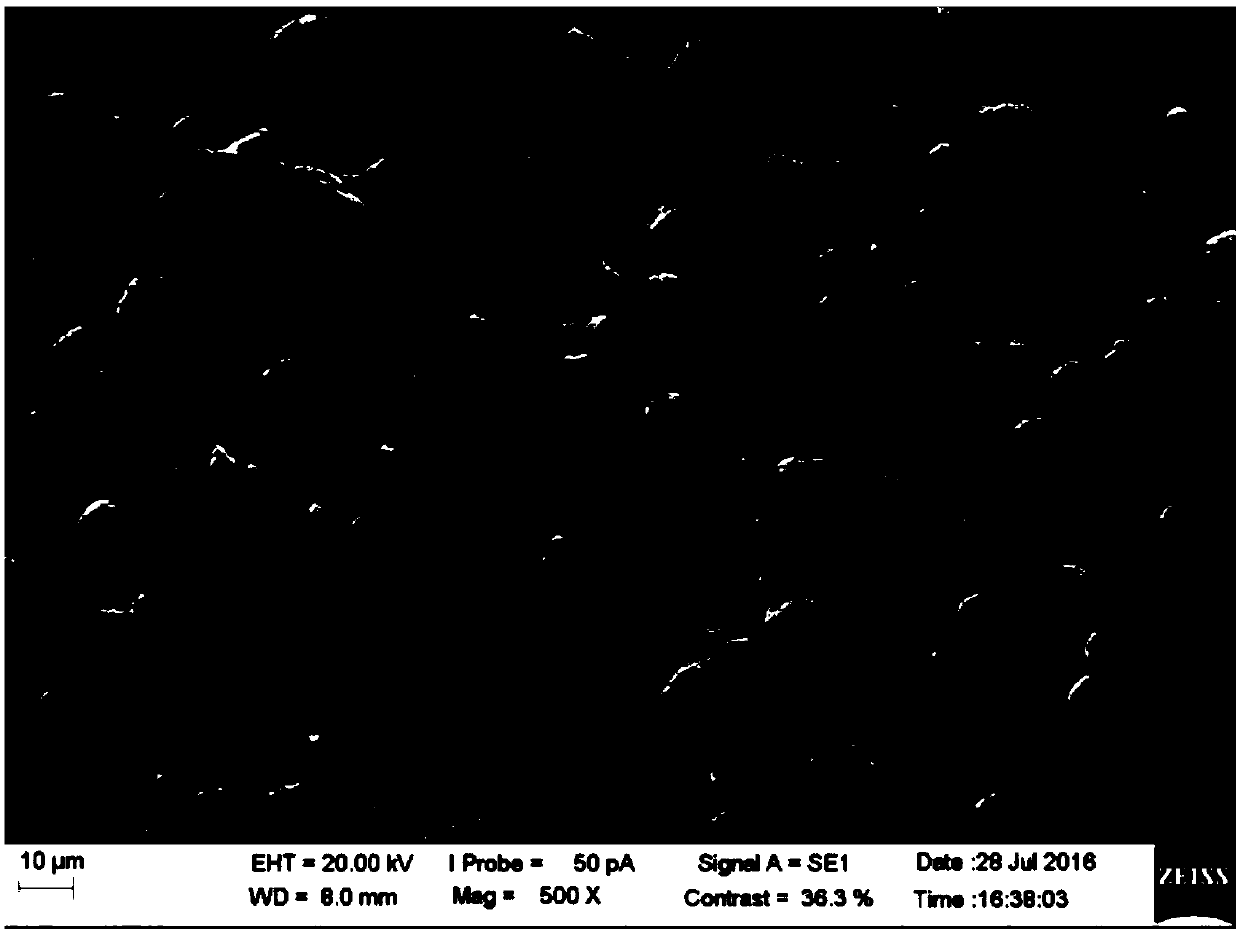

Image

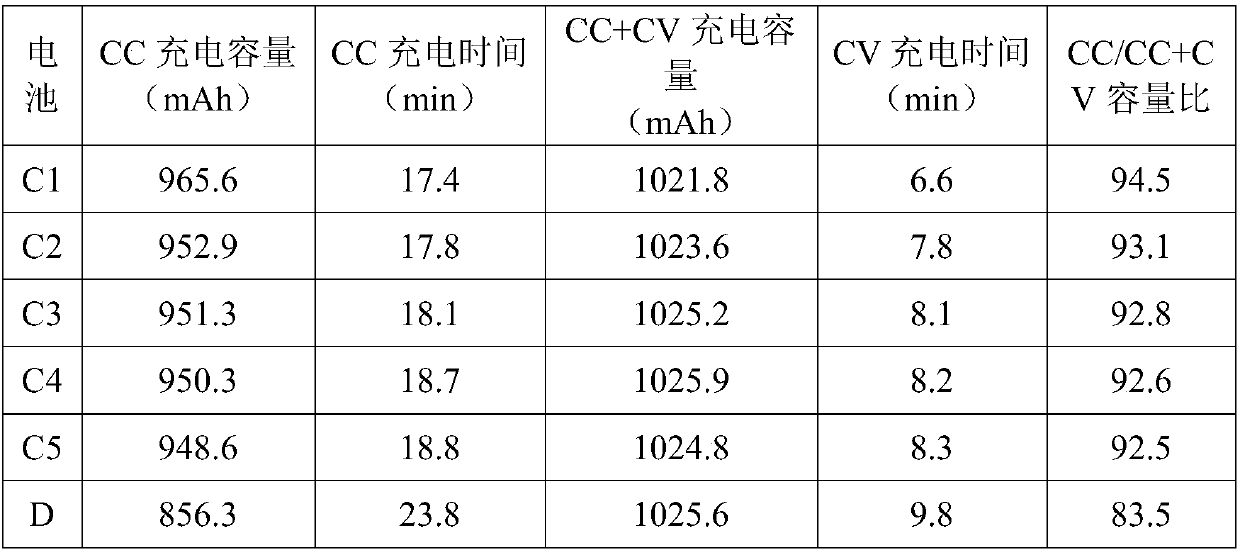

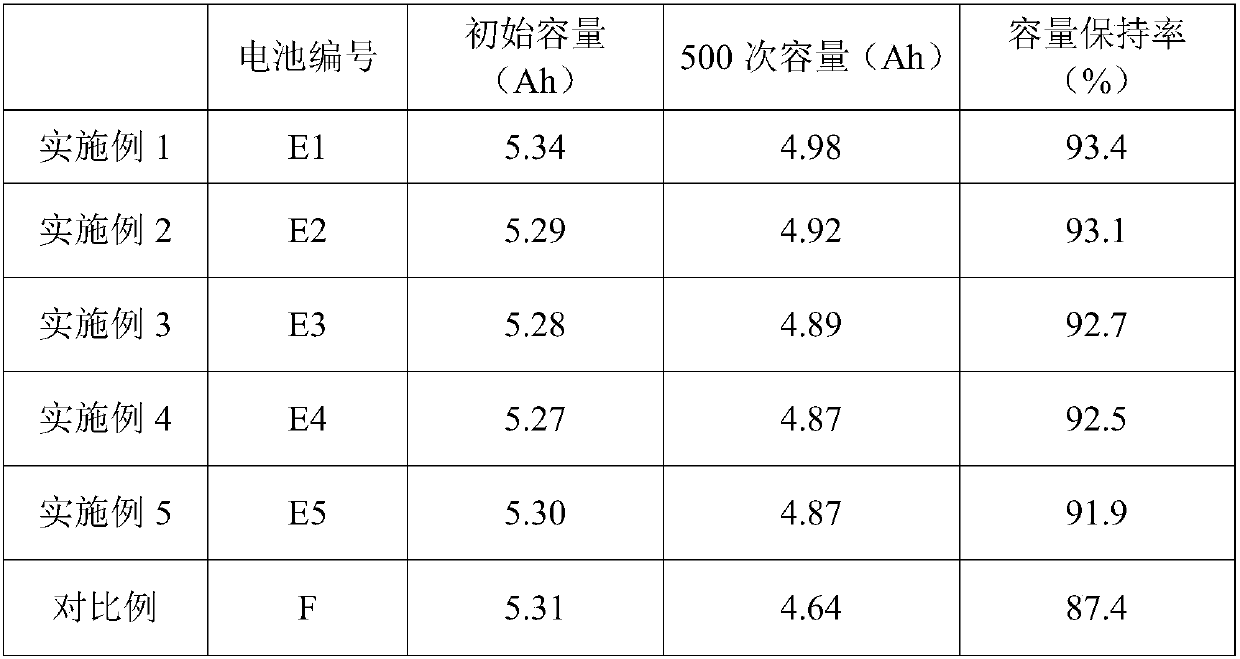

Examples

Embodiment 1

[0032] The preparation method of the carbon composite negative electrode material of the present embodiment comprises the following steps:

[0033] 1) Add 5 mL of isopropanol solution of phenolic resin with a concentration of 0.5 mol / L to 1000 mL of an aqueous solution of graphene oxide with a concentration of 5 mg / mL, mix and disperse evenly, and pass gas oxidant chlorine gas into the mixed liquid for 30 min , the gas flow rate is 10mL / min, while stirring to make it evenly mixed to obtain the pretreatment mixture;

[0034] 2) Add the above-mentioned pretreatment mixture into a high-pressure reactor, the pressure in the reactor is 2MPa, and the temperature is controlled at 180°C for 6 hours, then filtered, the solid is vacuum-dried at 50°C for 48 hours, and crushed to obtain a high-density composite powder body, carbonized at 800°C for 4h to obtain a hard carbon / graphene composite;

[0035] 3) Add 100mL of a conductive dispersion of carbon nanotubes with a mass fraction of 4%...

Embodiment 2

[0038] The preparation method of the carbon composite negative electrode material of the present embodiment comprises the following steps:

[0039] 1) Add 1mL of tetrahydrofuran solution of epoxy resin with a concentration of 1mol / L to 1000mL of graphene oxide aqueous solution with a concentration of 1mg / mL. The flow rate of feeding is 1mL / min, while stirring to make it evenly mixed to obtain the pretreatment mixture;

[0040] 2) Add the above-mentioned pretreatment mixture into a high-pressure reactor, the pressure in the reactor is 1.0 MPa, and the temperature is controlled at 150°C for 12 hours, then filtered, and the solid is vacuum-dried at 50°C for 24 hours, crushed to obtain a high-density composite Powder, carbonized at 800°C for 4 hours to obtain a hard carbon / graphene composite material;

[0041] 3) Add 100mL of a conductive dispersion of carbon nanotubes with a mass fraction of 1% in water to 1000mL of an aqueous solution of sucrose with a mass fraction of 1%, and ...

Embodiment 3

[0044] The preparation method of the carbon composite negative electrode material of the present embodiment comprises the following steps:

[0045] 1) Add 10mL of pyridine solution of furfural resin with a concentration of 0.1mol / L to 1000mL of an aqueous solution of graphene oxide with a concentration of 10mg / mL. After mixing and dispersing evenly, pass gas oxidant ozone into the mixed solution for 60min, and the gas The flow rate of feeding is 50mL / min, while stirring to make it mix evenly to obtain the pretreatment mixture;

[0046] 2) Add the above-mentioned pretreatment mixture into a high-pressure reactor, the pressure in the reactor is 5MPa, and the temperature is controlled at 200°C for 2 hours, then filtered, the solid is vacuum-dried at 50°C for 96 hours, and crushed to obtain a high-density composite powder body, carbonized at 800°C for 4h to obtain a hard carbon / graphene composite;

[0047] 3) Add 100mL of a conductive dispersion of carbon nanotubes with a mass fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com