Method for preparing nano-selenium from nano-aggregates of camellia plants and nano-selenium prepared by the method

A technology of nano selenium and aggregates, applied in the field of nano selenium, can solve the problems of instability and limited application scope, and achieve the effect of synergistic effect of anti-cancer activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A kind of method that utilizes camellia plant nano-aggregate to prepare nano-selenium.

[0036] (1) Accurately weigh 4.5g of green tea into a 250mL Erlenmeyer flask, add 225mL of boiling water, bathe in boiling water for 30min, shake once every 10min, suction filter while hot, cool to constant volume.

[0037] (2) Pipette 4mL of tea soup into the inner tube of a 100KDa ultrafiltration tube, centrifuge at 4000g for 20min at 4°C; collect the inner / outer tube solutions to obtain different particle size ranges (D H >10nm and D H ≤10nm) nano-aggregate solution, freeze-dried to obtain freeze-dried powder, ready to use.

[0038] (3) Prepare 10 mM sodium selenite solution and 100 mM vitamin C solution respectively.

[0039] (4) Take green tea nano-aggregate freeze-dried powder (D H >10nm) 40mg (400mg / L) in a 5mL centrifuge tube, transferred to a beaker with 10mL ultrapure water, added 72mL ultrapure water, stirred evenly, and passed through a 0.8μm filter membr...

Embodiment 2

[0042] Embodiment 2: A kind of method that utilizes camellia plant nano-aggregate to prepare nano-selenium.

[0043] Compared with embodiment 1, the difference is only in:

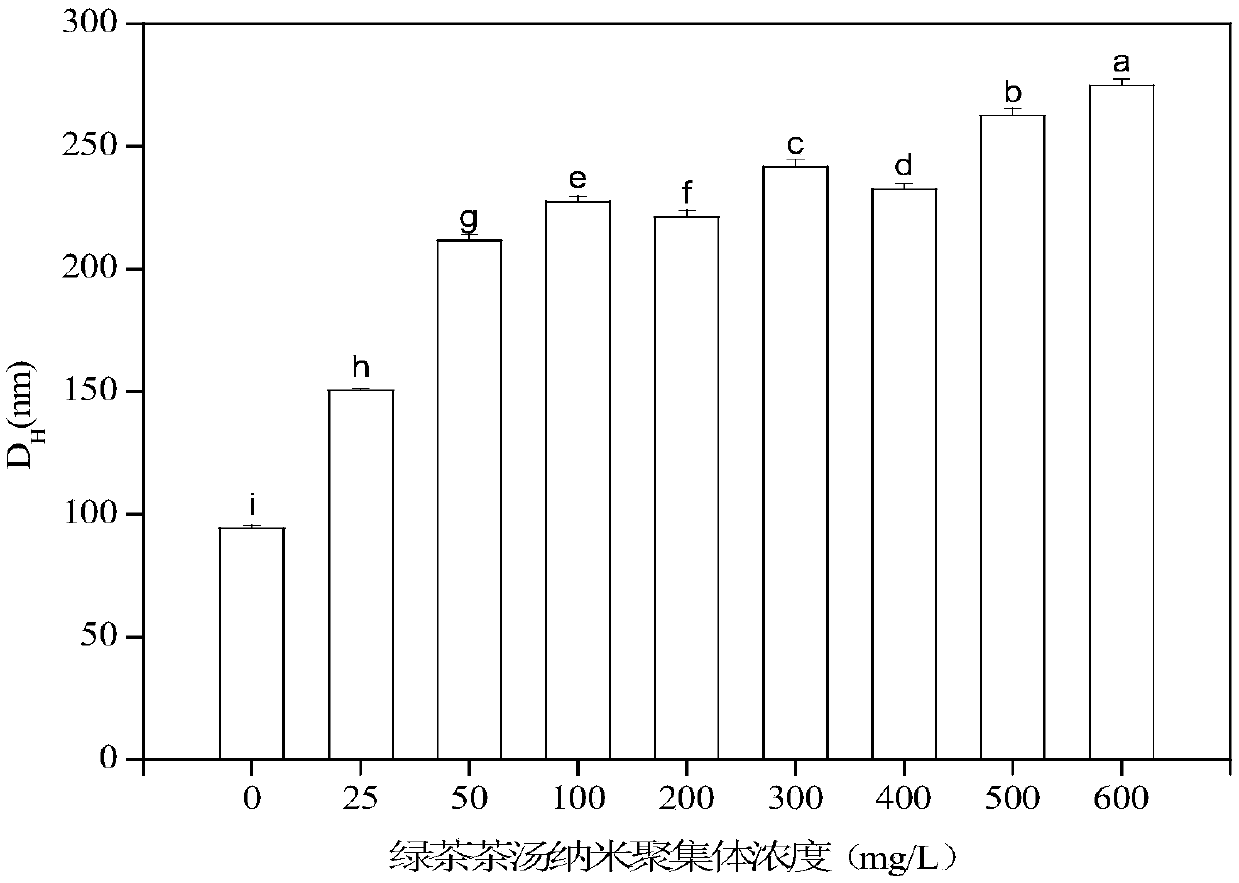

[0044] Weigh the freeze-dried powder of green tea nano-aggregate (D H >10nm) 2.5, 5, 10, 20, 30, 40, 50, 50mg (25, 50, 100, 200, 300, 400, 500, 600mg / L) in a 5mL centrifuge tube, transfer to Add 72mL of ultrapure water to the beaker, stir well, and pass through a 0.8μm membrane filter. The concentration of sodium selenite in the fixed system is 1mM. According to the ratio of reactants, add a certain amount of 10mM sodium selenite solution to Vc:sodium selenite 8:1 (mmol:mmol), mix well and let stand for 15min, then add A certain amount of 100mM vitamin C solution was mixed evenly, and the reaction was allowed to stand for 24 hours to obtain a nano-selenium colloidal solution. The chemical properties of the colloid were measured, and the results were as follows: figure 2 As shown, comprehensively consid...

Embodiment 3

[0045] Embodiment 3: A kind of method that utilizes camellia plant nano-aggregate to prepare nano-selenium.

[0046] Compared with embodiment 1, the difference is only in:

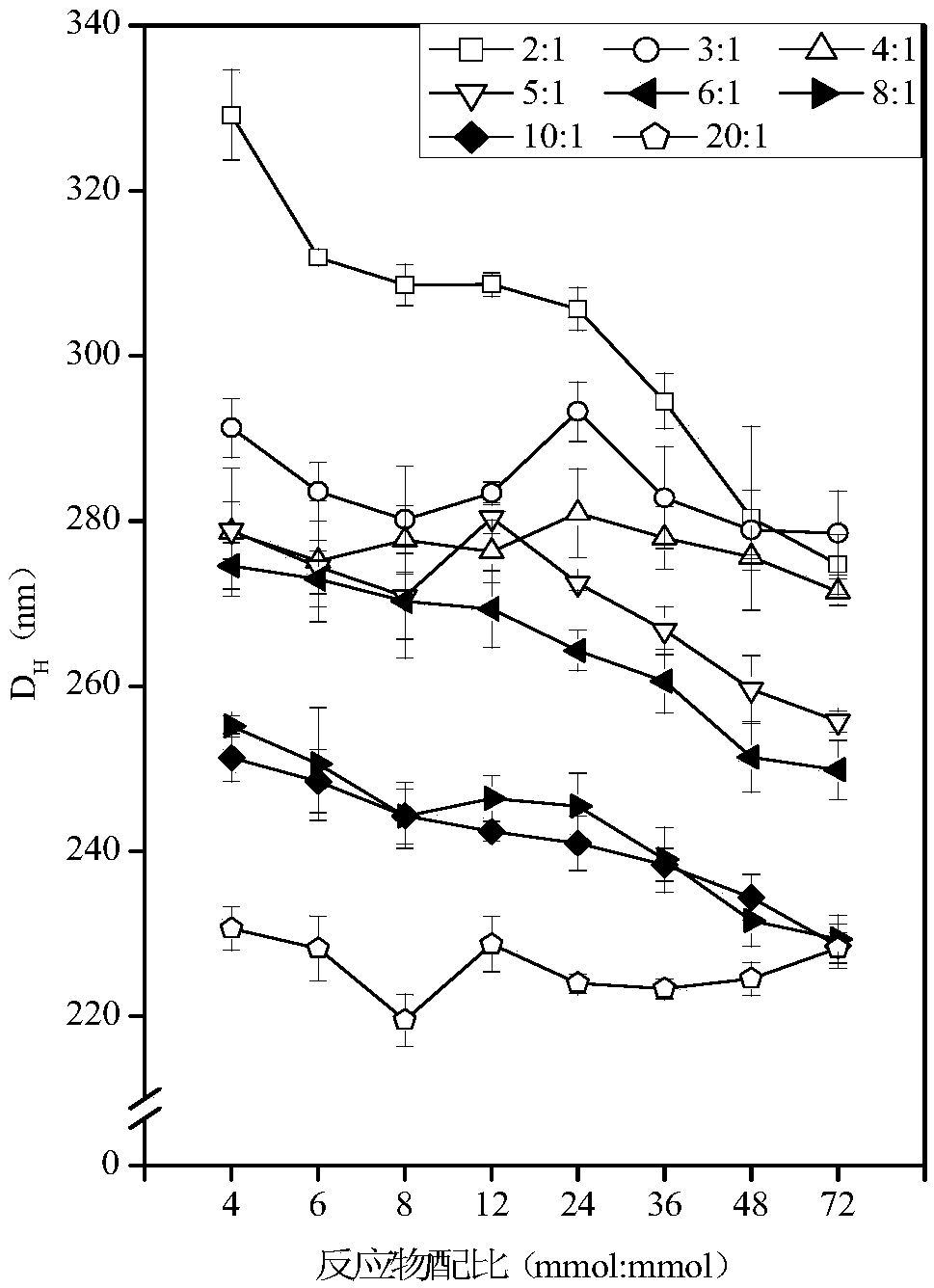

[0047] Weigh the freeze-dried powder of green tea nano-aggregate (D H >10nm) 40mg (400mg / L) in a 5mL centrifuge tube, transferred to a beaker with 10mL ultrapure water, added 72mL ultrapure water, stirred evenly, and passed through a 0.8μm filter membrane. The concentration of sodium selenite in the fixed system is 1mM. According to the ratio of reactants, add a certain amount of 10mM sodium selenite solution to Vc:sodium selenite 8:1 (mmol:mmol), mix well and let stand for 15min, then add A certain amount of 100mM vitamin C solution was mixed, and the reaction was allowed to stand for 4, 6, 8, 12, 24, 36, 48, and 72 hours to obtain a nano-selenium colloidal solution, and its colloidal chemical properties were measured. The results are as follows: figure 1 As shown, when the reaction time is 24h, the ave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com