Fluorescent material

A fluorescent material, fluorescent yellow technology, applied in the field of fluorescent materials, can solve the problem of insufficient fluorescent brightness and achieve the effect of enhancing fluorescent intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

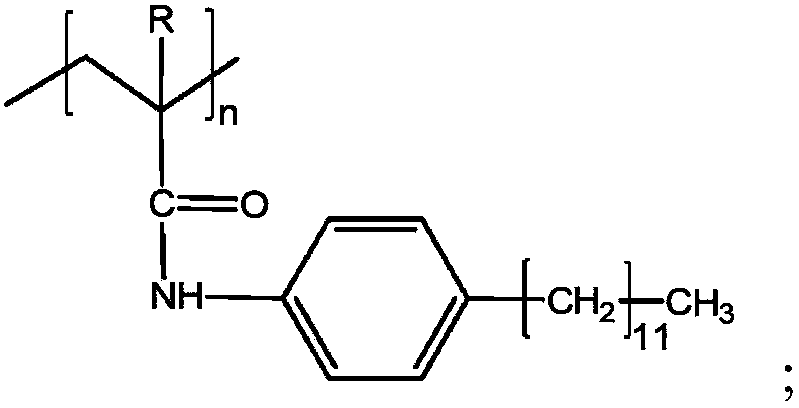

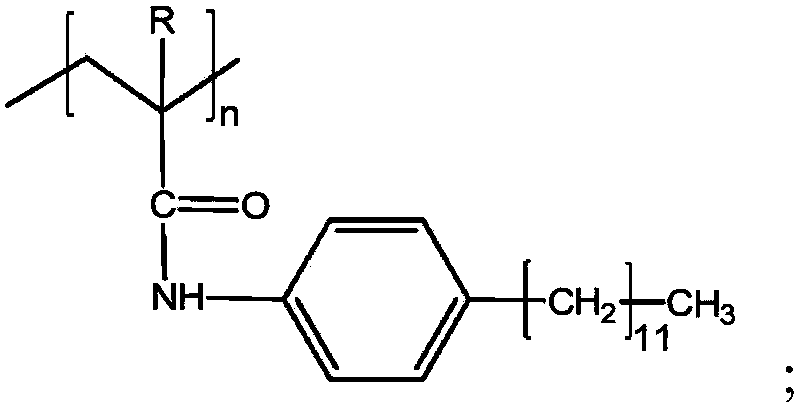

[0014] A fluorescent material, which consists of the following components in parts by weight: 50 parts of N-R substituent-p-nitroaniline, 8 parts of zinc silicate, 5 parts of zinc cadmium sulfide, 15 parts of fluorescent yellow, 2 parts of morin, and cyclic phenol 12 parts of compound, 6 parts of zirconia, 5 parts of alumina, 8 parts of garnet, 6-8 parts of mesoporous acrylamide polymer nanoparticles, wherein in the structural formula of mesoporous acrylamide polymer nanoparticles, R is hydrogen, and n is 500-550.

Embodiment 2

[0016] A fluorescent material, which consists of the following components in parts by weight: 40 parts of N-R substituents-p-nitroaniline, 4 parts of zinc silicate, 5 parts of zinc cadmium sulfide, 8 parts of fluorescent yellow, 2 parts of morin, and cyclic phenol 10 parts of compound, 3 parts of zirconia, 2 parts of alumina, 4 parts of garnet, 5 parts of mesoporous acrylamide polymer nanoparticles, wherein in the structural formula of mesoporous acrylamide polymer nanoparticles, R is hydrogen, and n is 400- 490.

Embodiment 3

[0018] A fluorescent material, which consists of the following components by weight: 55 parts of N-R substituent-p-nitroaniline, 8 parts of zinc silicate, 10 parts of zinc cadmium sulfide, 15 parts of fluorescent yellow, 2 parts of morin, and cyclic phenol 15 parts of compound, 9 parts of zirconia, 7 parts of alumina, 10 parts of garnet, and 10 parts of mesoporous acrylamide polymer nanoparticles, wherein in the structural formula of mesoporous acrylamide polymer nanoparticles, R is hydrogen, and n is 500- 550.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com