Biological fermentation process for using chicken dung in feed production

A bio-fermentation and feed-based technology, applied in the field of bio-engineering, can solve the problems of low level of feed utilization, complex production process and high production cost, and achieve the effects of improving the nutritional value of feed, reducing environmental pollution and preventing diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

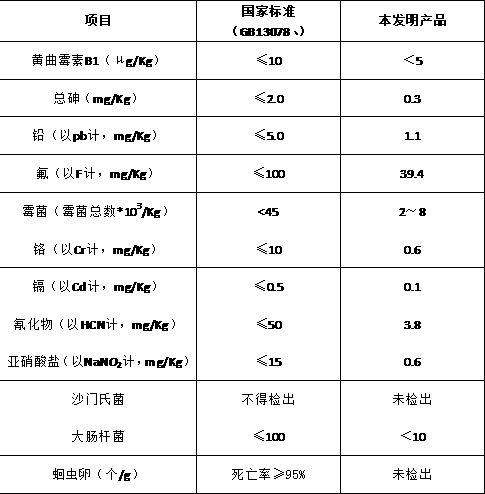

Image

Examples

Embodiment 1

[0040] A biofermentation process for utilizing chicken manure as feed, the specific process steps comprising:

[0041] (1) Ingredients: Mix evenly according to the ratio of 80 parts of chicken manure, 10 parts of corn flour, 5 parts of bran, 0.1 part of ammonium sulfate, 2 parts of urea, 0.05 part of potassium dihydrogen phosphate, and 0.03 part of magnesium sulfate, and adjust the content of the material The water content is 40% to 50%, and the dry and wet standard is suitable for holding it tightly with hands to drip water;

[0042] (2) Aerobic fermentation: Inoculate the activated mold, yeast, Bacillus subtilis, and thermophilic heterotrophic ammonia-oxidizing bacteria seed solution into the medium at a ratio of 1.2:1.8:0.6:1, and the total inoculation amount is solid culture 4wt% of base, after mixing thoroughly, compost and ferment, ventilate and cultivate 27h; Described mold is the mixed bacterial liquid of Aspergillus niger, Sporosporium thermophila 1:1, and described s...

Embodiment 2

[0047] A biofermentation process for utilizing chicken manure as feed, the specific process steps comprising:

[0048] (1) Ingredients: Mix evenly according to the ratio of 80 parts of chicken manure, 10 parts of corn flour, 5 parts of bran, 0.1 part of ammonium sulfate, 2 parts of urea, 0.05 part of potassium dihydrogen phosphate, and 0.03 part of magnesium sulfate, and adjust the content of the material The water content is 40% to 50%, and the dry and wet standard is suitable for holding it tightly with hands to drip water;

[0049] (2) Aerobic fermentation: Inoculate the activated mold, yeast, Bacillus subtilis, and thermophilic heterotrophic ammonia-oxidizing bacteria seed solution into the medium at a ratio of 1.2:1.8:0.6:1, and the total inoculation amount is solid culture 4wt% of base, after mixing thoroughly, compost and ferment, ventilate and cultivate 27h; Described mold is Aspergillus niger, and described saccharomycete is the mixed bacterium of Candida utilis and m...

Embodiment 3

[0054] A biofermentation process for utilizing chicken manure as feed, the specific process steps comprising:

[0055] (1) Ingredients: Mix evenly according to the ratio of 80 parts of chicken manure, 10 parts of corn flour, 5 parts of bran, 0.1 part of ammonium sulfate, 2 parts of urea, 0.05 part of potassium dihydrogen phosphate, and 0.03 part of magnesium sulfate, and adjust the content of the material The water content is 40% to 50%, and the dry and wet standard is suitable for holding it tightly with hands to drip water;

[0056] (2) Aerobic fermentation: Inoculate the activated mold, yeast, Bacillus subtilis, and thermophilic heterotrophic ammonia-oxidizing bacteria seed solution into the medium at a ratio of 1.2:1.8:0.6:1, and the total inoculation amount is solid culture 4wt% of base, after mixing thoroughly, compost and ferment, ventilated and cultivated for 27h; the mold is Sporiosporium thermophilic, and the yeast is the mixed bacteria of Candida utilis and molasses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com