Method for preparing ginkgo biloba leaf extract and application thereof in cigarettes

A technology for Ginkgo biloba leaves and extracts, which is applied in the field of preparation of Ginkgo biloba extracts, can solve the problems of inconspicuous product characteristic aroma, inability to meet usage requirements, unsatisfactory natural feeling, etc., and achieves improved comprehensive utilization rate and high extraction efficiency. , to avoid the effect of aroma loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

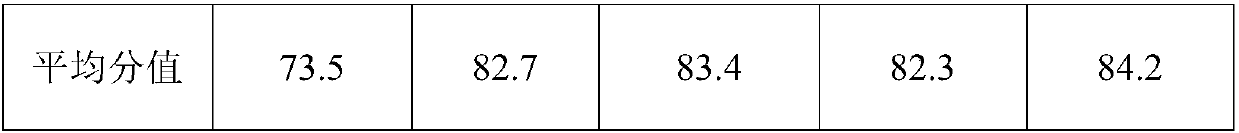

Embodiment 1

[0025] (1) After cleaning and draining the fresh ginkgo leaves, slice them for later use, then mix the flaked ginkgo leaves with 60% ethanol solution according to the ratio of 1:10, put them into microwave extraction equipment for extraction, and set the microwave power It is 550W, and the system temperature is set to rise from room temperature to 50-65°C within 10-30 minutes. After 0.5 hours of treatment, the filtrate is collected after filtration to obtain Ginkgo biloba extract A.

[0026] (2) Collect the ginkgo leaf residue in step (1), add 5 times the water of quality, add the biological agent of 0.5% mass ratio 1:1:0.5), after stirring evenly, incubate and ferment for 6 hours at pH 4 and temperature 30°C to obtain a hydrolysis fermentation broth. Add food-grade 95% ethanol (alcohol concentration in the system is 50%) to the hydrolysis fermentation broth, reflux extraction in a constant temperature water bath at 60°C for 3 times, filter and combine the filtrates to obtain ...

Embodiment 2

[0029] (1) After fresh ginkgo leaves are cleaned and drained, slice them for later use, then mix the flake ginkgo leaves with 30% ethanol solution according to the ratio of 1:8, put them into microwave extraction equipment for extraction, and set the microwave power It is 350W, and the system temperature is set to rise from room temperature to 50-65°C within 10-30 minutes. After treatment for 1 hour, the filtrate is collected after filtration to obtain Ginkgo biloba extract A.

[0030] (2) Collect the ginkgo leaf residue in step (1), add 4 times the water of quality, add the biological agent of 0.1% mass ratio 1:1:1), after stirring evenly, incubate and ferment for 12 hours at pH 6 and temperature 50°C to obtain a hydrolysis fermentation broth. Add food-grade 95% ethanol (the alcohol concentration in the system is 40%) to the hydrolysis fermentation broth, extract twice in a constant temperature water bath at 65°C under reflux, filter and combine the filtrates to obtain Ginkgo...

Embodiment 3

[0033] (1) After fresh ginkgo leaves are washed and drained, slice them for later use, then mix the flake ginkgo leaves with 45% ethanol solution according to the ratio of 1:6, and put them into microwave extraction equipment for extraction. It is 450W, and the system temperature is set to rise from room temperature to 50-65°C within 10-30 minutes. After 0.7 hours of treatment, the filtrate is collected after filtration to obtain Ginkgo biloba extract A.

[0034](2) Collect the ginkgo leaf residue in step (1), add 3 times the water of quality, add the biological agent of 0.3% mass ratio 1:2:0.5), after stirring evenly, incubate and ferment for 9 hours at pH 5.5 and temperature 35°C to obtain a hydrolysis fermentation broth. Add food-grade 95% ethanol (alcohol concentration in the system is 35%) to the hydrolysis fermentation broth, reflux extraction in a constant temperature water bath at 70°C for 3 times, filter and combine the filtrates to obtain Ginkgo biloba extract B.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com