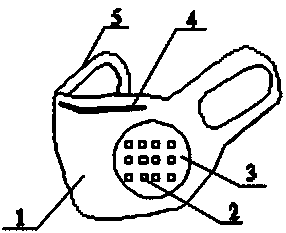

Preparation method of spherical filtering material for eliminating sulfur dioxide and mouth and nose mask using filtering material

A technology of sulfur dioxide and filter material, applied in the field of oral and nasal masks, can solve the problems of low utilization value, high operating cost, secondary pollution, etc., and achieve the effects of easy operation, prevention of secondary pollution, and reduction of breathing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Kaolin powder (300 mesh) 90g Active coke (230 mesh) 110g 5A zeolite (210 mesh) 150g Modified fly ash (190 mesh) 80g The preparation method is as follows:

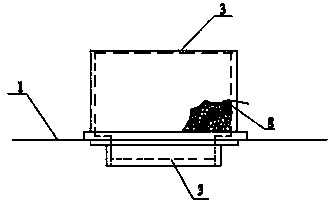

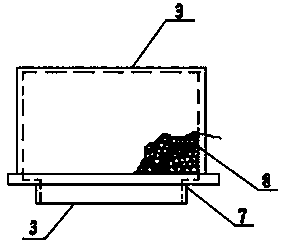

[0043] Weigh each raw material according to the formula amount, after mixing and stirring evenly, under the condition of adding water to the automatic sprayer to moisten, the total amount of water added accounts for 26% of the weight percentage of the powdery material, roll into balls through a pelletizing machine, and burn at 130°C After 3 hours of preparation, it becomes a porous spherical filter material, which is filled in the filter box, used as a filter element of the mouth and nose mask, and assembled into the mouth and nose mask.

Embodiment 2

[0045] Kaolin powder (340 mesh) 130g Active coke (270 mesh) 130g 5A zeolite (260 mesh) 230g Modified fly ash (210 mesh) 100g The preparation method is as follows:

[0046] Weigh each raw material according to the formula amount, after mixing and stirring evenly, under the condition of adding water to the automatic sprayer to moisten, the total amount of water added accounts for 50% of the weight percentage of the powdery material, roll into balls through a pelletizing machine, and burn at 180°C After 2.5 hours of preparation, it becomes a porous spherical filter material, which is filled in the filter box, used as a filter element of the mouth and nose mask, and assembled into the mouth and nose mask.

Embodiment 3

[0048] Kaolin powder (350 mesh) 180g Active coke (300 mesh) 160g 5A zeolite (320 mesh) 320g Modified fly ash (230 mesh) 140g The preparation method is as follows:

[0049] Weigh each raw material according to the formula amount, after mixing and stirring evenly, under the condition of adding water to the automatic sprayer to moisten, the total amount of water added accounts for 35% of the weight percentage of the powdery material, roll into balls through a pelletizing machine, and burn at 240 ° C. After 2 hours of preparation, it becomes a porous spherical filter material, which is filled in the filter box, used as a filter element of the mouth and nose mask, and assembled into the mouth and nose mask.

[0050] Table 1 Sulfur dioxide before and after treatment with the mouth and nose mask of the present invention, unit: ppm.

[0051]

[0052] As can be seen from Table 1, use the mouth and nose mask of spherical filter material of the present invention to remove SO in the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com