LED lamp

A technology for LED lamps and light sources, which is applied to cooling/heating devices of lighting devices, lighting and heating equipment, semiconductor devices of light-emitting elements, etc. Production cost, the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

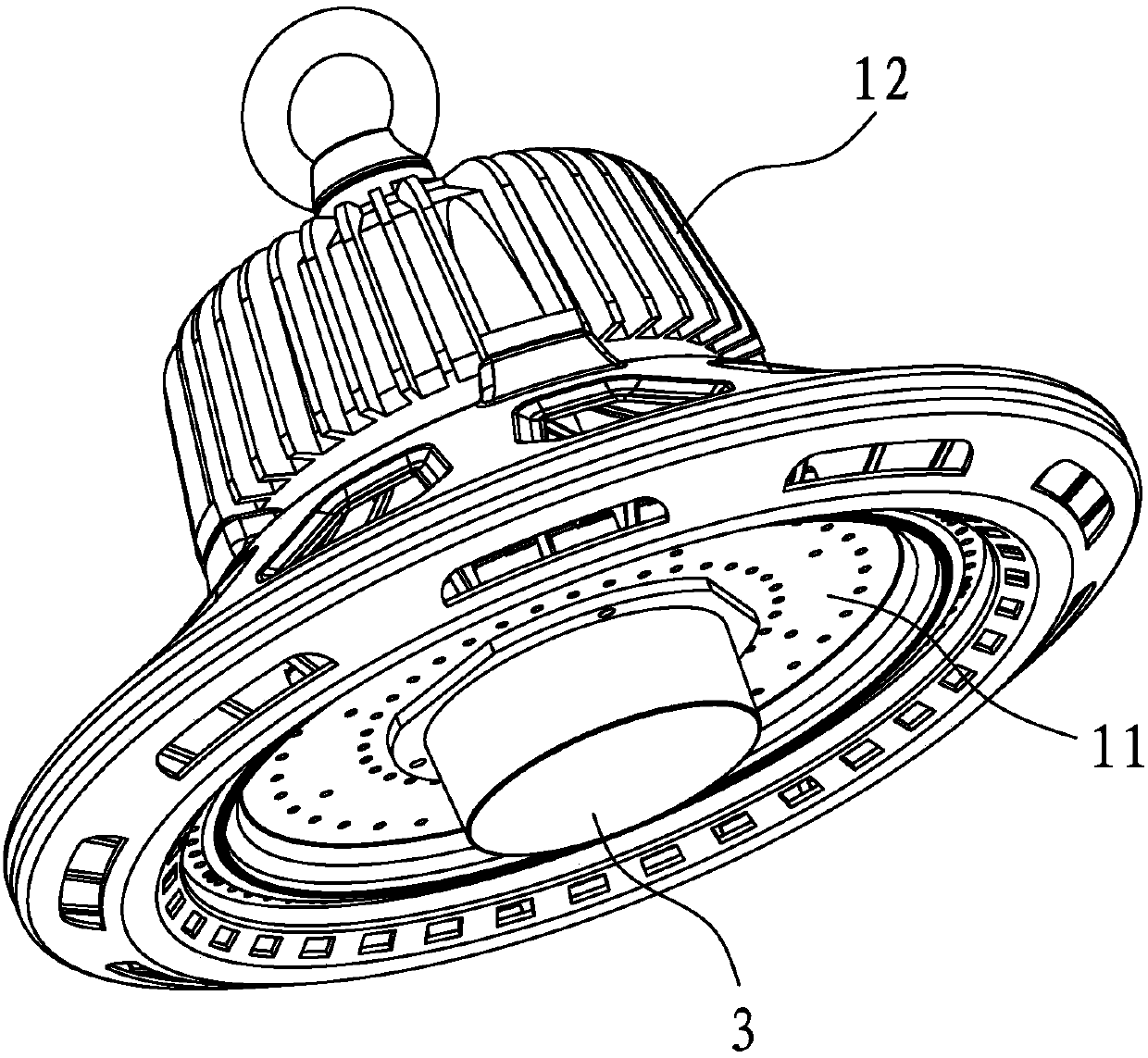

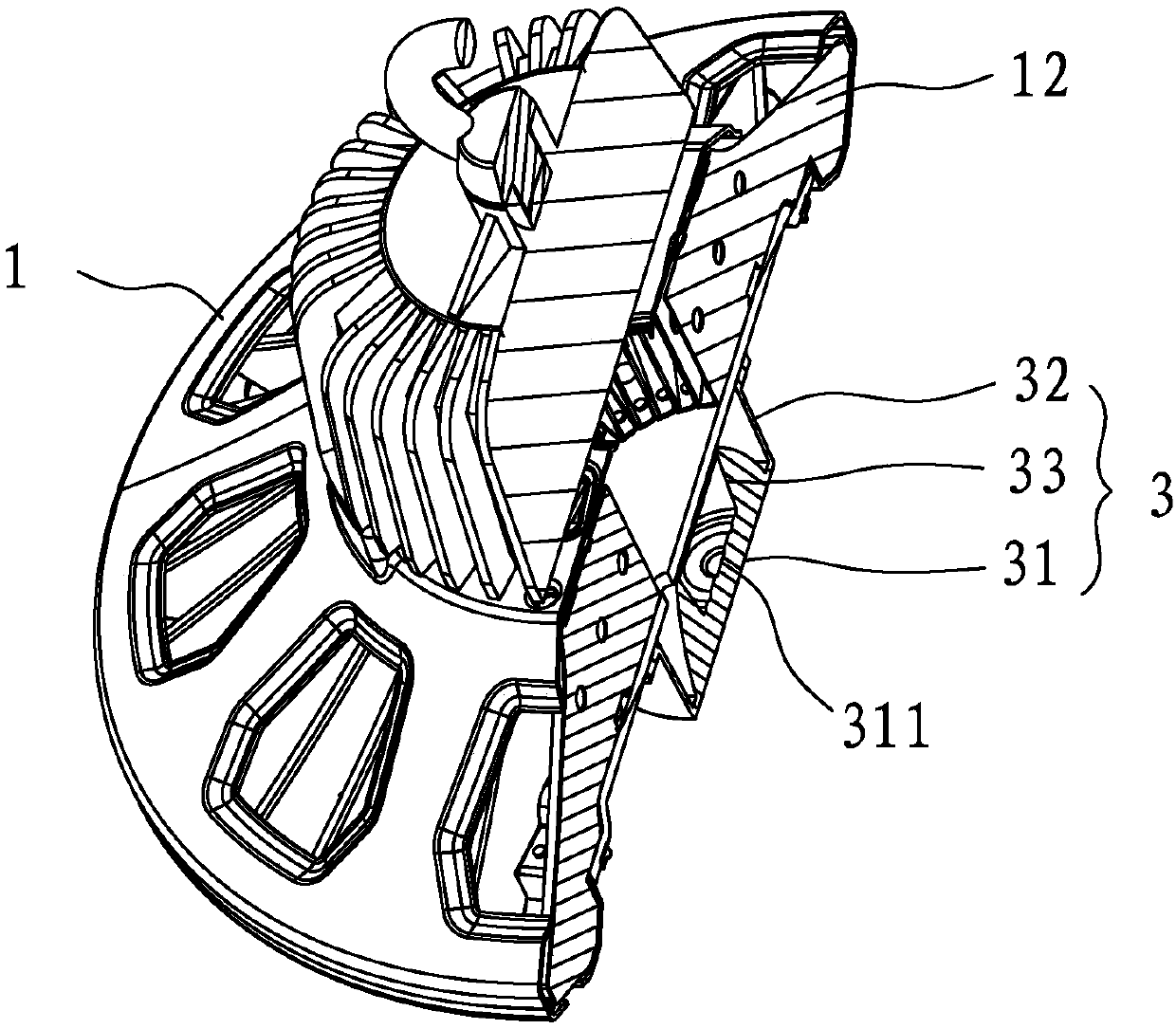

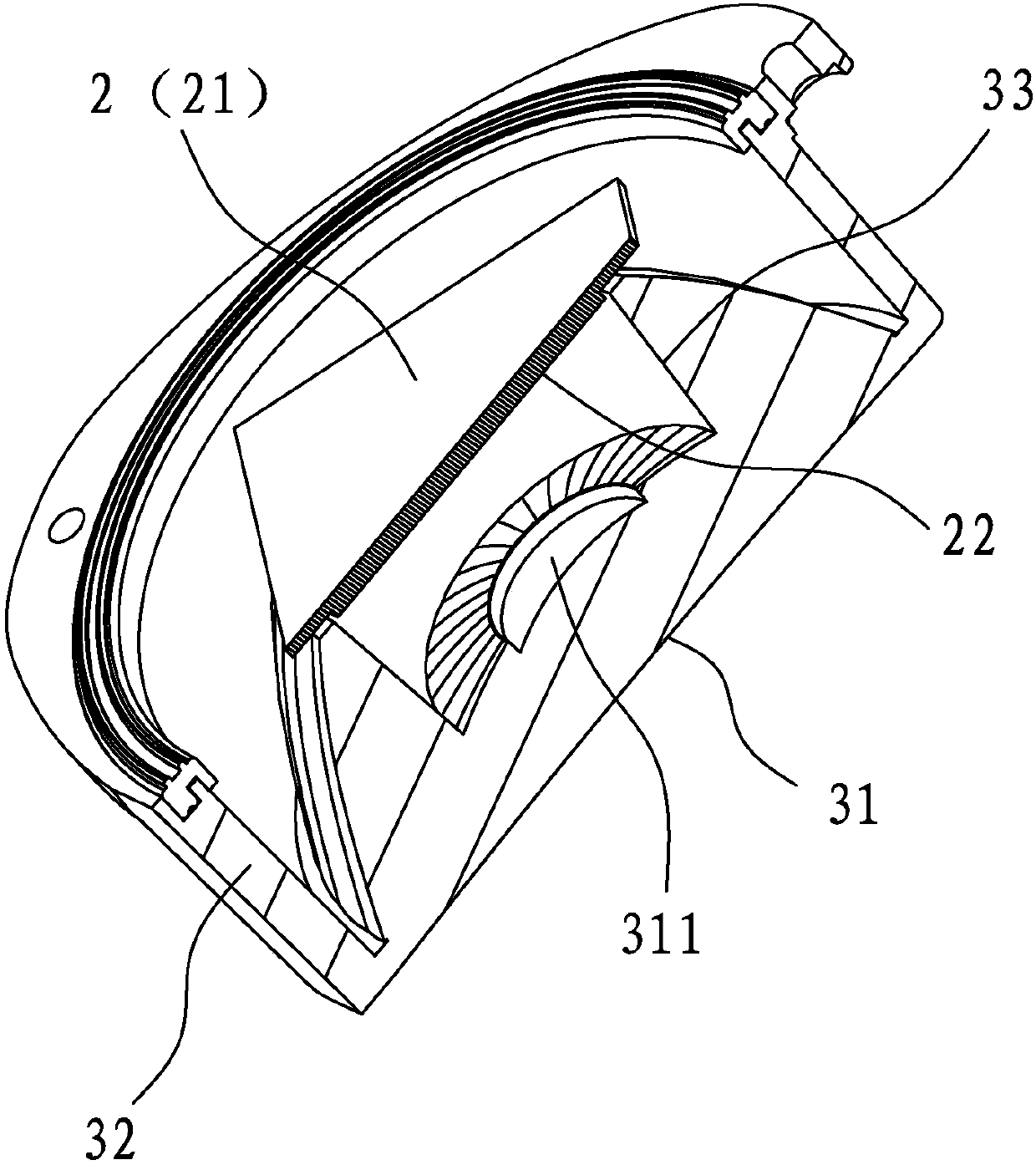

[0049] The radiator 1 has a heat conduction plate 11 and several heat dissipation fins 12 connected to the heat conduction plate 11, and the heat conduction plate 11 and the plurality of heat dissipation fins 12 are connected by riveting. In this way, compared with the direct contact between the heat conducting plate 11 and the main body of the heat sink 12 in the traditional technology, the contact area between each other is greatly increased by riveting, and the heat dissipation performance is improved.

Embodiment approach 2

[0051] The heat sink 1 has a heat conduction plate 11 and several heat sinks 12 connected to the heat conduction plate 11. A nickel-plated layer is also formed on the heat conduction plate 11. The heat conduction plate 11 passes through the nickel-plated layer and the solder layer in turn. It is connected with several heat sinks 12 by welding. By soldering after nickel plating, the contact area between the heat conducting plate 11 and the main body of the heat sink 12 is greatly increased, thereby greatly improving the heat dissipation efficiency.

Embodiment approach 3

[0053] The heat sink 1 has an integrated heat sink 12 formed by cold forging process and a heat conduction bottom plate, and a nickel plating layer is also formed on the heat conduction bottom plate. Such direct one-piece molding improves heat dissipation efficiency and ensures work efficiency.

[0054] In this way, the present invention can greatly improve the integrity of the entire heat conduction channel by forming a nickel-plated layer and then cooperating with solder, and solves the disadvantage that aluminum materials cannot be soldered by means of nickel plating, thereby greatly improving the heat conduction and thermal conductivity of the entire LED lamp. The heat dissipation performance ensures that the entire LED lamp can work normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com