Catalyst for preparing alkene unsaturated aldehyde from alkene unsaturated alcohol and preparation method and application of catalyst

A catalyst and unsaturated technology, applied in chemical instruments and methods, physical/chemical process catalysts, carbon-based compound preparation, etc., can solve problems such as low selectivity, process safety, and poor reactivity, and achieve simple preparation methods and raw materials Cheap and easy to get, active and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

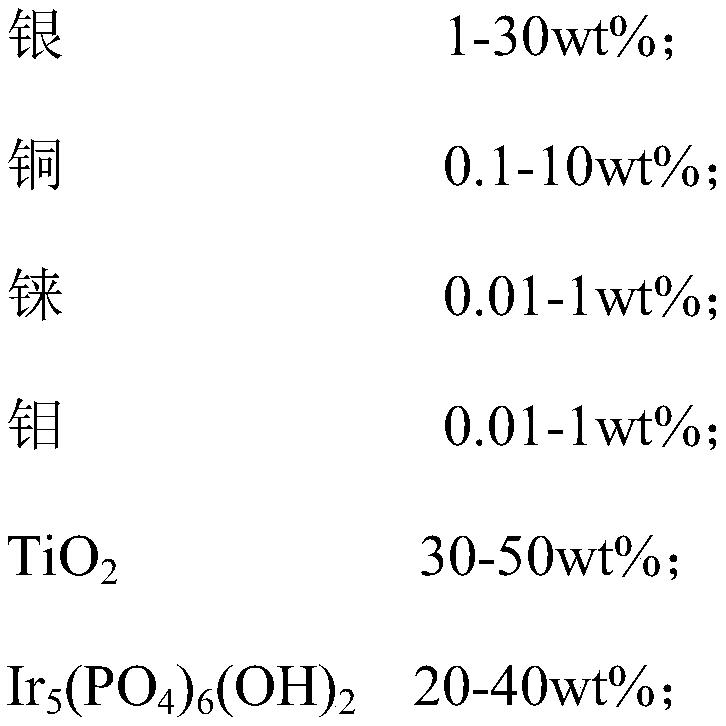

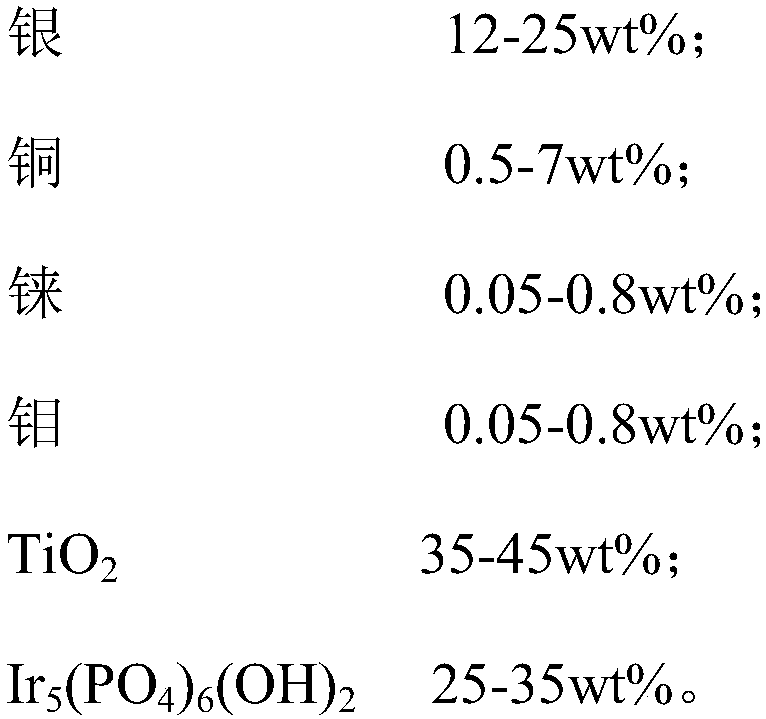

Method used

Image

Examples

Embodiment 1

[0048] Preparation of Catalyst A: Add 5.25g TiO to 43.24g concentration of 25wt% ammonia under stirring condition 2 Make it form a suspension, add 3.99g of Ir to this suspension 5 (PO 4 ) 6 (OH) 2 , reacted at 60°C for 5h, left at room temperature and aged for 11h, washed the obtained precipitate by centrifugation, freeze-dried and then roasted at 400°C for 5h as a carrier; 0.17g of AgNO3 was dissolved in 0.2mL of water, 0.20g (NH4)2C2O4 was dissolved in 0.32mL of water, and the two solutions were placed in a 40°C water bath to react under stirring conditions. Wash the precipitate after reacting for 1 hour, add 0.34 mL of 5 mol / L ethylenediamine aqueous solution to the precipitate after washing for 2-3 times to obtain a silver-amine complex solution, add 3.08 gCu(NO 3 ) 2 , 0.002gRe(NO 3 ) 3 , 0.38gMo(NO 3 ) 4 Dissolved into a uniform solution, added the prepared carrier to the above solution, stirred for about 1 h, evaporated the solvent at 100°C, and calcined at 35...

Embodiment 2

[0052] Preparation of Catalyst B: Except using 3.06 g AgNO 3 , 2.16g Cu(NO 3 ) 2 , 0.01g Re(NO 3 ) 3 , 0.30gMo(NO 3 ) 4 , 3.68g TiO 2 , 4.06g Ir 5 (PO 4 ) 6 (OH) 2 . In the obtained catalyst B, silver accounts for 18.50wt%, copper accounts for 7wt%, rhenium accounts for 0.05wt%, molybdenum accounts for 0.80wt%, TiO 2 Accounted for 35%, Ir5(PO 4 ) 6 (OH) 2 Accounting for 38.65wt%.

[0053] Catalyst B Reactivity Test: Tested with reference to the method of Example 1, the reaction conversion rate was 72%, and the selectivity of 3-methyl-2-butene-1-aldehyde was 97%.

[0054] Catalyst B service life test: test with reference to the method of Example 1, the reaction activity did not decrease within 4000h, the conversion rate remained at 69-72%, the selectivity remained at 97-98%, and the reaction conversion rate began to decrease after 4200 hours. After 5000 hours, the conversion rate dropped below 50%.

Embodiment 3

[0056] Preparation of Catalyst C: Except using 4.13 g AgNO 3 , 0.15g Cu(NO 3 ) 2 , 0.09g Re(NO 3 ) 3 , 0.16gMo(NO 3 ) 4 , 4.20g TiO 2 , 3.53g Ir 5 (PO 4 ) 6 (OH) 2 . In the obtained catalyst C, silver accounts for 25wt%, copper accounts for 0.5wt%, rhenium accounts for 0.43wt%, molybdenum accounts for 0.43wt%, TiO 2 40%, Ir 5 (PO 4 ) 6 (OH) 2 Accounting for 33.65wt%.

[0057] Catalyst C Reactivity Test: Tested with reference to the method of Example 1, the reaction conversion rate was 75%, and the selectivity of 3-methyl-2-butene-1-aldehyde was 99%.

[0058] Catalyst C service life test: test with reference to the method of embodiment 1, the reaction activity does not see reduction in 4000h, the conversion rate is maintained at 73-75%, the selectivity is maintained at 97-99%, and the reaction conversion rate begins to decrease after 4100 hours. After 5000 hours, the conversion rate dropped below 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com