Production process of cyanamide

A production process and cyanamide technology, applied in the field of cyanamide production technology, can solve problems such as production cost of explosive products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

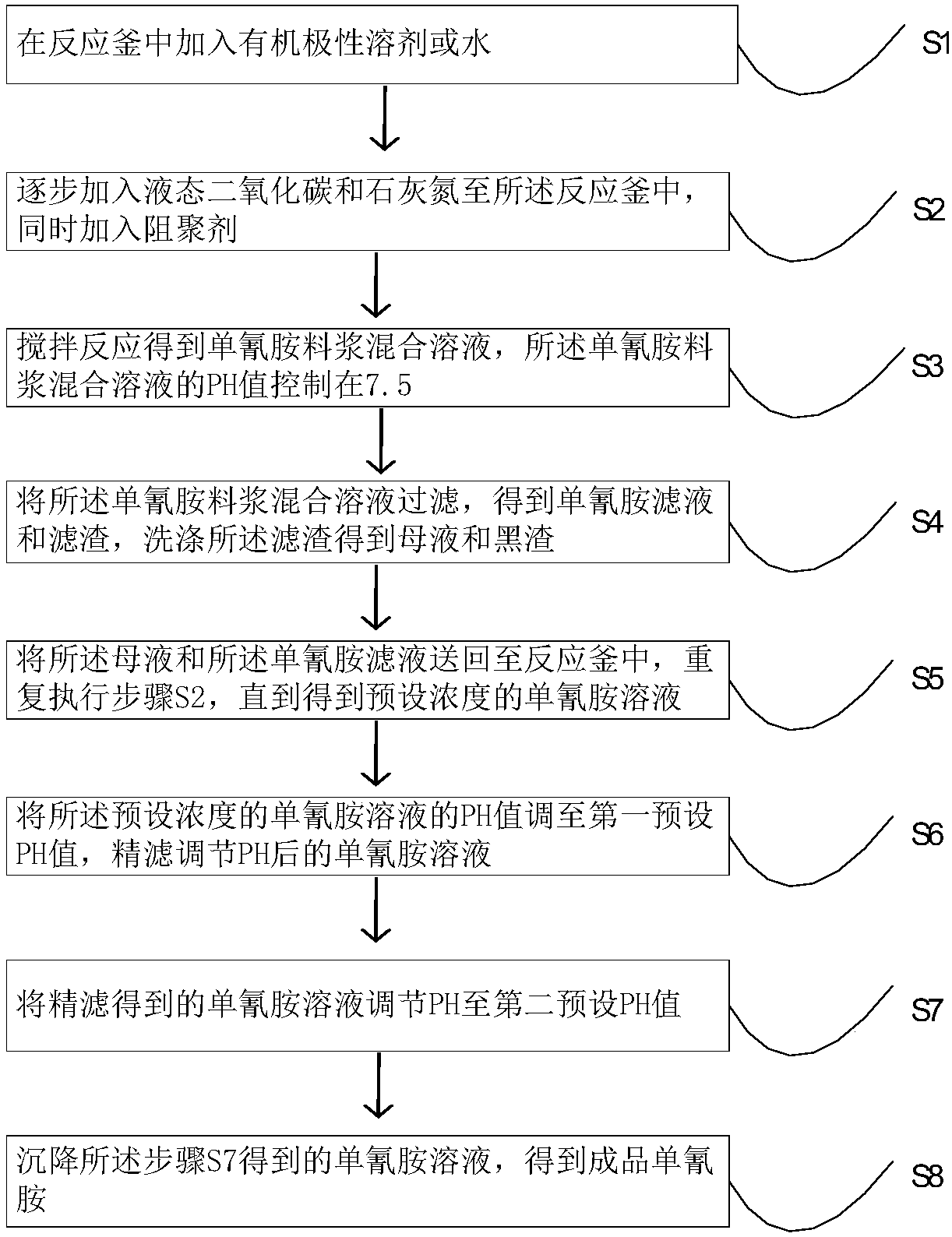

[0027] refer to figure 1 , which shows a kind of cyanamide production process provided by the embodiment of the present invention, comprising the following steps:

[0028] S1, add organic polar solvent or water in the reactor;

[0029] It should be noted that the organic polar solvent may optionally be methanol, ethanol, etc., and the water is supplied by a washing water metering device.

[0030] S2, gradually adding liquid carbon dioxide and lime nitrogen to the reaction kettle, and simultaneously adding a polymerization inhibitor;

[0031] Specifically, the mass of the polymerization inhibitor accounts for 0.01%-0.5% of the water mass, and the liquid carbon dioxide is provided by a carbon dioxide liquid supply station. The lime nitrogen is transported to the lime nitrogen storage silo by the pneumatic conveying system, and the lime nitrogen dust generated by the pneumatic conveying system is collected by the air box pulse bag filter on the top of the lime nitrogen storage ...

Embodiment 2

[0047] Embodiment two, the difference with embodiment one is only:

[0048] Further, step S5 includes: when the preset concentration of the cyanamide solution is 50%, the number of times to repeat step S2 is 4 times, and when step S2 is executed for the first 3 times, the reaction temperature in the reactor should be controlled to 15°C, when performing the fourth step S2, the reaction temperature in the reactor should be controlled to 10°C

[0049] If the preset concentration of the cyanamide solution is 30%, the number of times to repeat step S2 is 2 times, and when step S2 is performed, the reaction temperature in the reactor should be controlled at 15°C.

[0050] Further, air is delivered to the reactor in step S2. The reaction kettle is equipped with a forced circulation pipeline, which not only improves the working environment, but also improves the utilization of liquid carbon dioxide. While treating the waste gas, it provides fresh air to participate in the reaction an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com