Mineral source culture medium and preparation method thereof

A technology for cultivation substrates and minerals, applied in the agricultural field, can solve problems such as burning seedlings, and achieve the effects of good ventilation and water permeability, reasonable configuration and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation of mineral source cultivation substrate of the present invention, concrete steps are as follows:

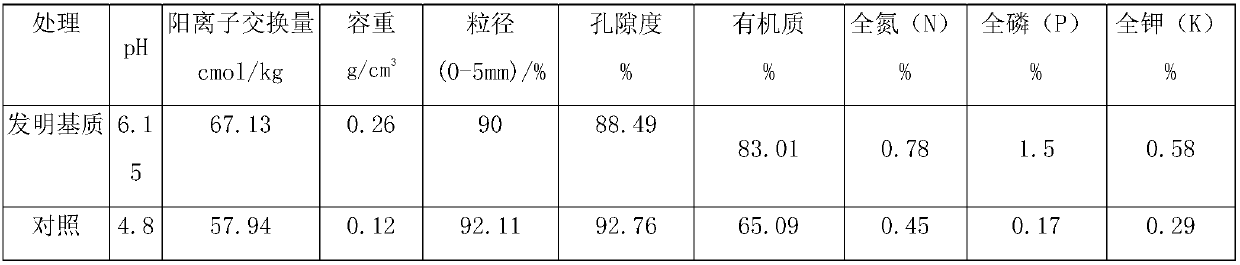

[0020] Taking the preparation of 10L mineral source matrix as an example, the single components of coconut peat, peat soil, perlite, humic acid, yellow phosphorus slag (coarse) and phosphorus tailings are in order according to the volume ratio of 4:2:2:1:0.5:0.5 Mix, and select the Miracle.Gro nutrient soil that is sold well in the market and has a good cultivation effect as a control (CK).

[0021] (1) Take 4L coconut peat; soak the coconut peat pieces in water, dry them in the air until the water content reaches below 20%, and crush them to 0-6mm.

[0022] (2) Measure 2L of peat soil;

[0023] (3) Measure 2L perlite; (large particle size, rinse the dust with running water, and place it in a ventilated place to dry)

[0024] (4) Measure 1L humic acid;

[0025] (5) Measure 0.5L yellow phosphorus slag; (particle size 1-2mm)

[0026] (6) Measure 0.5L phos...

Embodiment 2

[0033] The mineral source cultivation substrate prepared in Example 1 was used in the cultivation experiment of Chinese cabbage, and at the same time, Miracle.Gro nutrient soil was selected as the control (CK). The substrate humidity is adjusted to 80% of the water holding capacity in the field, try to select pakchoi seeds of the same size (weighing method), use 10% H 2 o 2 The solution was soaked for 30 minutes for disinfection, and then rinsed repeatedly with deionized water after treatment, dried and sowed. 40 days after planting, the plant height, leaf area, SPAD and fresh weight of the pakchoi were measured.

[0034] It can be seen from Table 2 that the plant height, leaf area, SPAD and fresh weight of pakchoi treated with mineral source matrix increased by 12.3%, 16.7%, 19.46% and 12.7% compared with the control. Miracle.Gro nutrient soil is a mainstream matrix product in the market, and its product quality has been widely praised. The effect of the mineral source matr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com