Biocompatible and thermosensitive nano-composite epoxy resin and preparation method thereof

A biocompatibility and nanocomposite technology, which is applied in the field of biocompatibility and temperature-sensitive nanocomposite epoxy resin and its preparation, can solve the problems of tissue engineering, poor mechanical comprehensive performance, and inconspicuous temperature sensitivity, etc. problem, to achieve the effect suitable for application, low cost and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

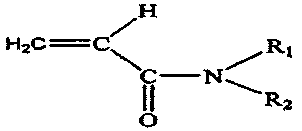

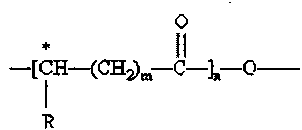

[0039] 1.20g of isopropylacrylamide, 0.25g of hectorite, 0.05g of polyhydroxybutyrate were added to 10mL of deionized water successively, in a sealed container at 20°C, nitrogen was introduced, ultrasonically dispersed for 30min, and stirred for 45min , until completely dispersed to form a homogeneous solution; the above mixed solution is cooled to 30°C with ice cubes, 0.01g of persulfate is added after 30min, and 20 uL of N,N,N'N'-tetramethylethylenediamine is injected after 10min, Under nitrogen protection, continue to stir for 10 min until the mixed solution begins to appear viscous; immediately pour the viscous mixed solution into a glass mold with a thickness of 2 mm, and stand at 20 °C for in-situ radical polymerization for 24 h. Then, the reaction product was soaked in deionized water for 2 weeks to obtain the biocompatible and temperature-sensitive nanocomposite epoxy resin.

[0040] The obtained nanocomposite epoxy resin: the volume phase transition temperature was 33...

Embodiment 2

[0042] 1.0g isopropylacrylamide, 0.2g lithium magnesium silicate, 0.3g poly(hydroxybutyrate monohydroxyvalerate) were added to 10mL deionized water successively, and in a sealed container at 20°C, nitrogen was introduced. , ultrasonic dispersion for 30min, stirring for 60min, until completely dispersed to form a homogeneous solution; the above mixed solution is cooled to 20C with ice cubes, 0.02g of persulfate is added after 30min, and 40uL of N,N,N'N'-40uL is injected after 10min Methylethylenediamine, under nitrogen protection, continue to stir for 10min, until the mixed solution begins to appear viscous; immediately pour the viscous mixed solution into a glass mold with a thickness of 2mm, and let stand at 25°C for in situ The free radical polymerization reaction is carried out for 20 hours, and then the reaction product is soaked in deionized water for 2 weeks to obtain the biocompatible and temperature-sensitive nanocomposite epoxy resin.

[0043] The obtained nanocomposi...

Embodiment 3

[0045] 1.3g of bisethylacrylamide, 0.15g of hectorite, 0.05g of poly-3-hydroxybutyric acid-3-hydroxycaproate (PI-Il3HHx) were added to 10mL of deionized water successively, and the sealant at 20°C was sealed. In the container, nitrogen was introduced, ultrasonically dispersed for 30min, and stirred for 30min, until completely dispersed to form a homogeneous solution; the above mixed solution was cooled to 3°C with ice cubes, 0.015g of ammonium persulfate was added after 30min, and 301-L N, N was injected after 10min. , N'N'-tetramethylethylenediamine, under nitrogen protection, continue to stir for 10min, until the mixed solution begins to appear viscous; immediately pour the viscous mixed solution into a glass mold with a thickness of 2mm, at 25 The in-situ radical polymerization reaction was carried out by standing at ℃ for 30 hours, and then the reaction product was immersed in deionized water for 2 weeks to obtain the biocompatible and temperature-sensitive nanocomposite ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com