Epoxy resin structure adhesive and preparation method thereof

A technology of epoxy structural adhesive and epoxy pretreatment, which is applied in the direction of epoxy resin adhesive, adhesive, adhesive type, etc. Insufficient operating time and other problems, to achieve the effect of high bonding strength, high mechanical properties, and long operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

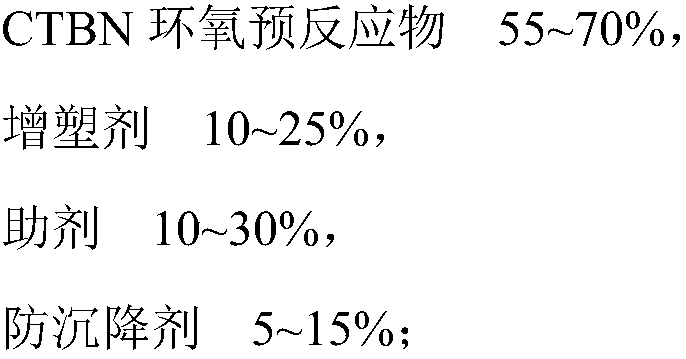

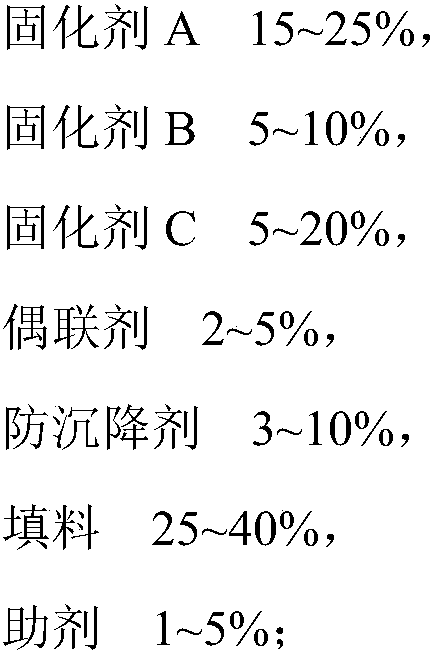

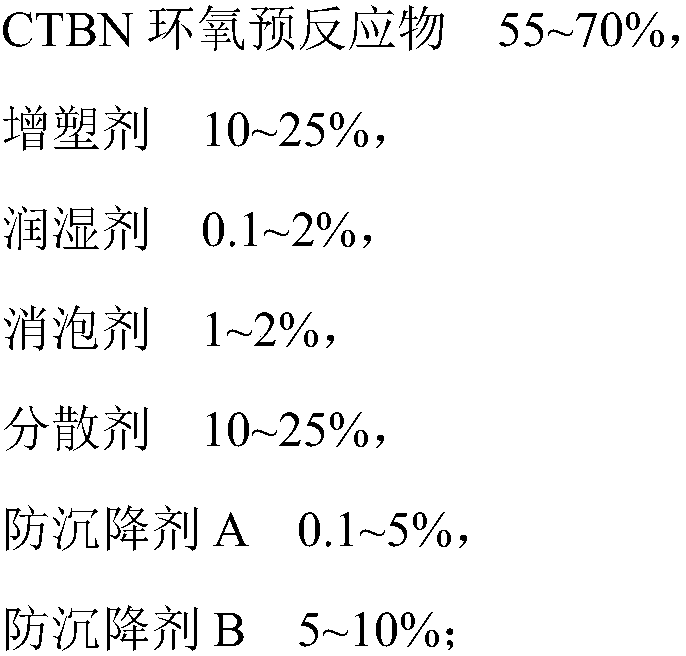

Embodiment 1

[0034]

[0035]

[0036] The above raw materials are commercially available, wherein the plasticizer is polyamide resin, the wetting agent is polyoxyethylene alkyl ether, the defoamer is mineral oil, the dispersant is sodium polyacrylate, and the anti-settling agent A is gas-phase dioxide silicon, anti-settling agent B is polyamide wax, curing agents A and B are organic amines, curing agent C is imidazoles, and coupling agent is γ-aminopropyltriethoxysilane.

[0037] The preparation method of this epoxy structural adhesive comprises the following steps:

[0038] (1) Preparation of component A: Weigh the raw materials according to the above weight ratio, add the CTBN epoxy pre-reactant into the dispersion kettle, slowly add the defoamer at a stirring speed of 100r / min, adjust the speed to 500r / min, and then Add dispersant, anti-sedimentation agent A, anti-settling agent B, and wetting agent, stir for 30 minutes until evenly stirred, add plasticizer, disperse for 60 minute...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap