Pitaya wine

A dragon fruit wine and pitaya technology, which is applied in the field of wine product materials, can solve the problems of pitaya fruit cannot be stored, pitaya fruit should not be transferred and sold, and is perishable and deteriorated, so as to alleviate the symptoms of incompatibility after drinking, shorten the fermentation time, and improve the aroma. full-bodied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

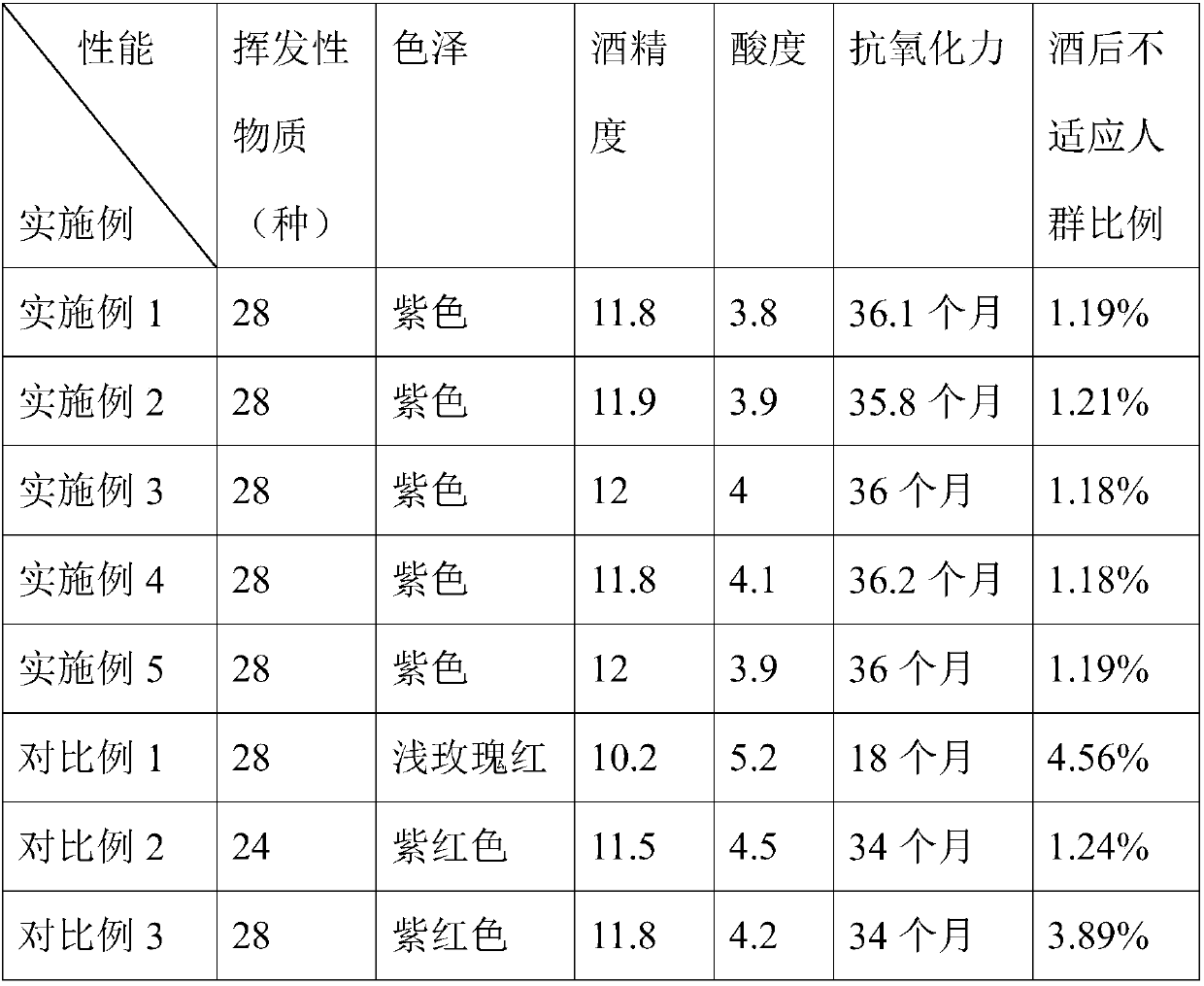

Examples

Embodiment 1

[0038]S1. Raw material pretreatment: collect fresh pitaya, clean and beat the pulp into pulp;

[0039] S2, fermentation: add auxiliary material in pitaya pulp, stir evenly, then be placed in fermentation container, and container mouth is sealed up and carry out anaerobic fermentation 45 days; Wherein, the auxiliary material that adds is accounted for dragon fruit pulp and auxiliary material total mass The percentage meter includes the following mass percentages: sugar: 0.5%, tannin: 0.05‰, yeast: 0.2‰, pectinase: 0.01‰, food antioxidant: 0.02‰, oak chips: 0.02‰, saponin: 0.05‰, aglycone : 0.02‰; the fermentation vessel is a stainless steel fermentation vessel;

[0040] S3, brewing: when the dragon fruit pulp is fermented to be completely dissolved into fruit juice, it is brewed into wine according to the conventional method;

[0041] S4, primary filtration: use a plate-and-frame diatomite filter to remove residues; the coating amount of diatomite filtered by the plate-and-fra...

Embodiment 2

[0048] S1. Raw material pretreatment: collect fresh pitaya, clean and beat the pulp into pulp;

[0049] S2, fermentation: add auxiliary material in pitaya pulp, stir evenly, then place in fermentation container, and container mouth is sealed up and carry out anaerobic fermentation 48 days; Wherein, the auxiliary material that adds is accounted for dragon fruit pulp and auxiliary material total mass The percentage meter includes the following mass percentages: sugar: 3.5%, tannin: 3.8‰, yeast: 3.7‰, pectinase: 3.5‰, food antioxidant: 3.5‰, oak chips: 1.7‰, saponin: 1.8‰, aglycone : 3.4‰; the fermentation vessel is a stainless steel fermentation vessel;

[0050] S3, brewing: when the dragon fruit pulp is fermented to be completely dissolved into fruit juice, it is brewed into wine according to the conventional method;

[0051] S4, primary filtration: use a plate-and-frame diatomite filter to remove residues; the coating amount of diatomite filtered by the plate-and-frame diatom...

Embodiment 3

[0058] S1. Raw material pretreatment: collect fresh pitaya, clean and beat the pulp into pulp;

[0059] S2, fermentation: add auxiliary material in pitaya pulp, stir evenly, then place in fermentation container, and container mouth is sealed up and carry out anaerobic fermentation 52 days; Wherein, the auxiliary material that adds is accounted for dragon fruit pulp and auxiliary material total mass The percentage meter includes the following mass percentages: sugar: 5%, tannin: 5‰, yeast: 5‰, pectinase: 5‰, food antioxidant: 5‰, oak chips: 2.5‰, saponin: 2.5‰, aglycone : 5‰; the fermentation vessel is a stainless steel fermentation vessel;

[0060] S3, brewing: when the dragon fruit pulp is fermented to be completely dissolved into fruit juice, it is brewed into wine according to the conventional method;

[0061] S4, primary filtration: use a plate-and-frame diatomite filter to remove residues; the coating amount of diatomite filtered by the plate-and-frame diatomite filter i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com