Oil-resistant and heat-resistant automobile engine hollow tube and preparation method thereof

一种汽车发动机、耐热的技术,应用在汽车发动机中空管领域,能够解决汽车发动机发生故障、难以同时达到、工作强度大等问题,达到工序简单、优异机械强度、优异耐热性和耐油性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

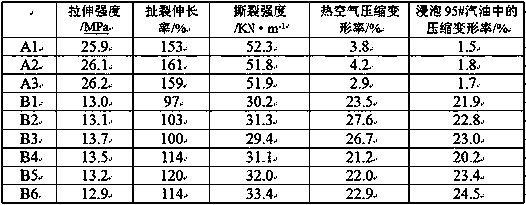

Examples

preparation example Construction

[0014] The invention provides a method for preparing an oil-resistant and heat-resistant automobile engine hollow pipe, comprising:

[0015] 1) Put water glass, graphene and tetrabutyl titanate in dilute sulfuric acid for soaking, washing and drying to obtain modified silica gel;

[0016] 2) Conduct contact reaction with expanded vermiculite, 3-aminopropyltriethoxysilane, graphite and hydrochloric acid solution, filter and take filter cake to obtain activation modifier;

[0017] 3) Mix and knead chloroprene rubber, fluororubber, polycaprolactam, cyclodextrin, kaolin, beeswax, sulfur, stearate, zinc chloride, sodium tungstate, the modified silica gel and the activation modifier , Molding to make oil-resistant and heat-resistant automobile engine hollow tubes.

[0018] In step 1) of the present invention, the amount of each material can be selected within a wide range, but in order to further improve the mechanical strength, heat resistance and oil resistance of the car engine ...

Embodiment 1

[0032] 1) Mix water glass, graphene, tetrabutyl titanate, and dilute sulfuric acid with a concentration of 2.5% by weight according to a weight ratio of 100:1.5:2.9:400, then stand at 45°C for 6 hours, wash with water, and Dry at 530°C for 1.5h to obtain modified silica gel;

[0033] 2) Mix expanded vermiculite, 3-aminopropyltriethoxysilane, graphite and hydrochloric acid solution with a concentration of 25% by weight according to the weight ratio of 100:8:6:180, and contact and react at 85°C for 10h, filter Take filter cake to make activation modifier;

[0034] 3) Neoprene, fluororubber, polycaprolactam, cyclodextrin, kaolin, beeswax, sulfur, stearate (potassium stearate), zinc chloride, sodium tungstate, modified silica gel and activation modifier Mix according to the weight ratio of 100:59:19:10:13:27:15:5:7:6.5:23:32, knead at 240°C and 4Mpa for 4 hours, and extrude (extrusion molding temperature is 200 ℃) to prepare oil-resistant and heat-resistant automotive engine hol...

Embodiment 2

[0036] 1) Mix water glass, graphene, tetrabutyl titanate, and dilute sulfuric acid with a concentration of 2% by weight according to the weight ratio of 100:1:2.5:300, then stand at 40°C for 5h, wash with water, and Dry at 500°C for 1 hour to obtain modified silica gel;

[0037] 2) Mix expanded vermiculite, 3-aminopropyltriethoxysilane, graphite and hydrochloric acid solution with a concentration of 20% by weight according to the weight ratio of 100:5:3:150, and contact and react at 80°C for 8h, filter Take filter cake to make activation modifier;

[0038] 3) Neoprene, fluororubber, polycaprolactam, cyclodextrin, kaolin, beeswax, sulfur, stearate (sodium stearate), zinc chloride, sodium tungstate, modified silica gel and activation modifier Mix according to the weight ratio of 100:55:17:8:10:22:10:3.5:5:5.5:21:30, knead at 230°C and 3.5Mpa for 3 hours, and extrude (extrusion molding temperature is 190°C) to produce oil-resistant and heat-resistant automotive engine hollow tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com