A method for preparing bio-aviation hydrocarbon fuels by thermochemical conversion of triglycerides

A technology of thermochemical conversion and triglyceride, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrogenation process, etc., can solve the problem of single molecular structure, achieve the effect of increasing the content of aromatic hydrocarbons and reducing the acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

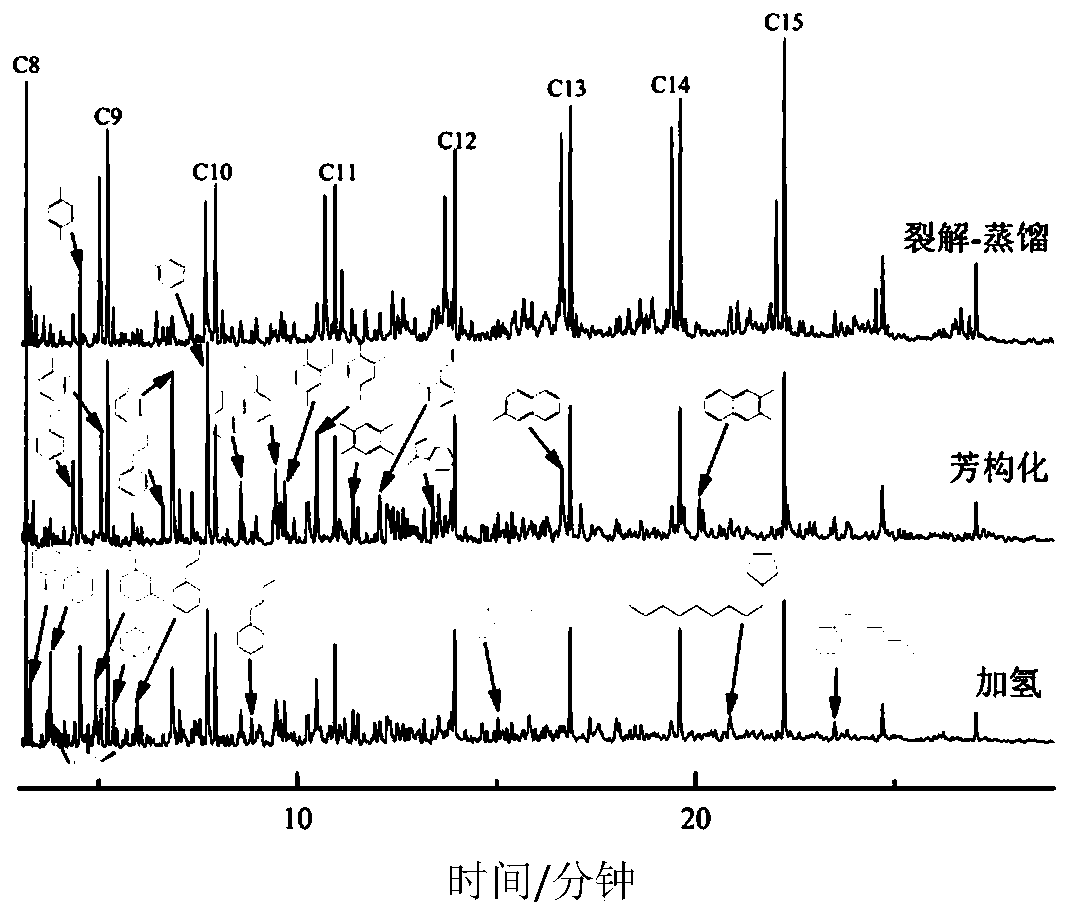

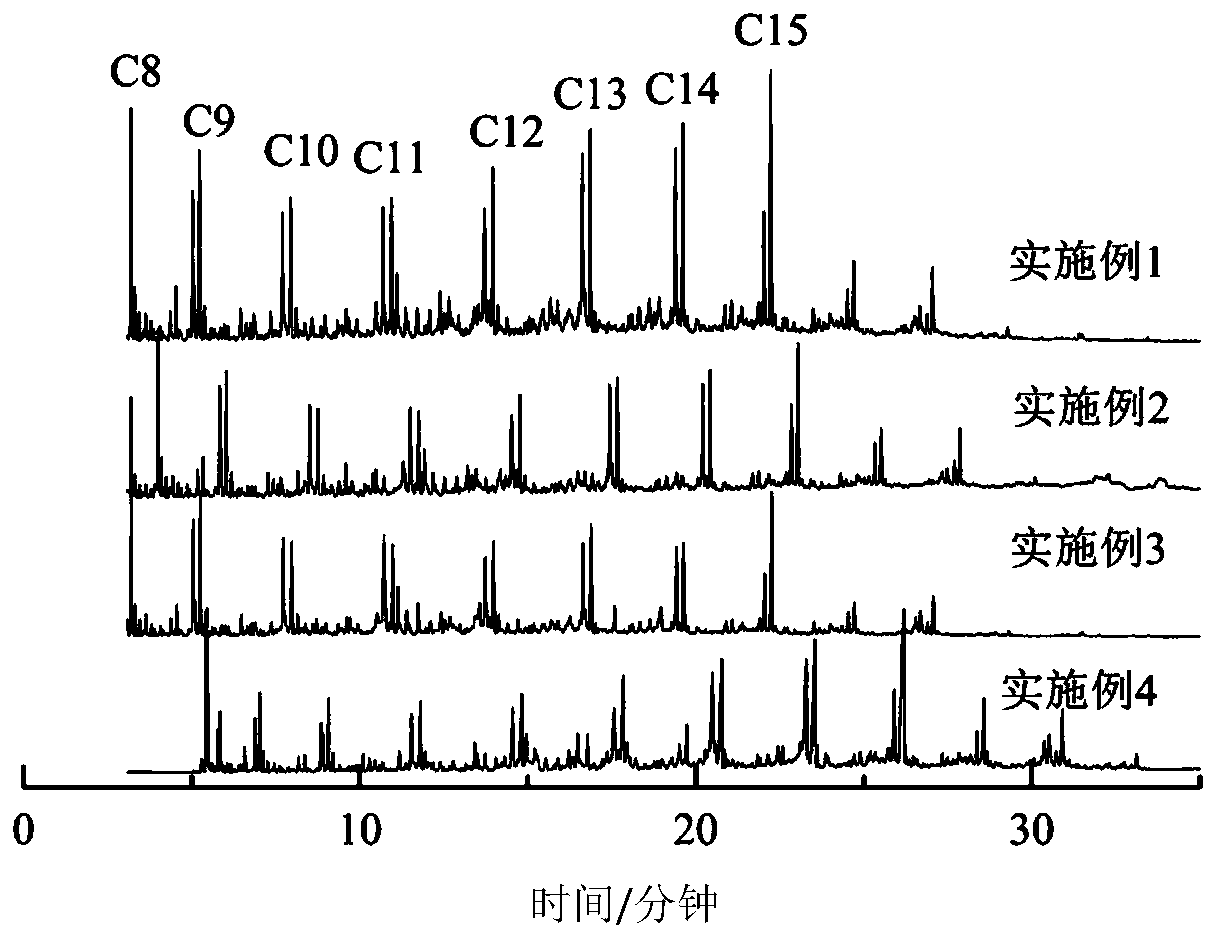

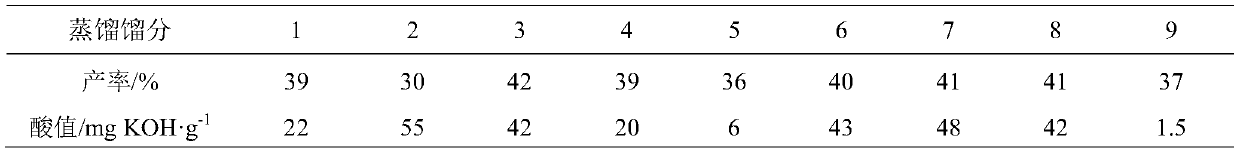

[0024] Add 1500g soybean oil and 10wt.% sodium carbonate into the pyrolysis reaction kettle, start stirring, and the temperature of the rectification column rises to 280°C-300°C. When the temperature of the reaction kettle rises to 350°C, condensed liquid appears, and the temperature is gradually raised to 450°C. Keep until no lysis liquid flows out. Atmospheric distillation is carried out on the cracked liquid, and fractions at 90°C to 270°C are collected. Take 80g fraction and 5wt.% HZSM-5 (Si / Al=27) catalyst in a high-pressure reactor, start stirring, the reactor is heated to 350°C, react for 6h, and remove the catalyst by centrifugation. Take 40g of the product from the previous step and 5wt.% Pd / C catalyst in a high-pressure reactor, feed hydrogen gas at 6MPa, start stirring, heat the reactor to 200°C, and react for 6 hours to obtain a mixture containing alkanes, aromatic hydrocarbons and naphthenes , which is bio-aviation fuel.

Embodiment 2

[0026] Add 1500g waste oil and 5wt.% sodium carbonate into the pyrolysis reaction kettle, start stirring, and the temperature of the rectification column rises to 280°C-300°C. When the temperature of the reaction kettle rises to 350°C, condensed liquid appears, and the temperature is gradually raised to 450°C. Keep until no lysis liquid flows out. Atmospheric distillation is carried out on the cracked liquid, and fractions at 90°C to 270°C are collected. Take 80g fraction and 5wt.% HZSM-5 (Si / Al=27) catalyst in a high-pressure reactor, start stirring, the reactor is heated to 350°C, react for 8h, and remove the catalyst by centrifugation. Take 40g of the product from the previous step and 5wt.% Pd / C catalyst in a high-pressure reactor, feed hydrogen gas at 6MPa, start stirring, heat the reactor to 200°C, and react for 6 hours to obtain a mixture containing alkanes, aromatic hydrocarbons and naphthenes , which is bio-aviation fuel.

Embodiment 3

[0028] Add 1500g soybean oil and 5wt.% sodium carbonate into the pyrolysis reactor, start stirring, and the temperature of the rectification column rises to 260°C-280°C. When the reactor heats up to 350°C, condensed liquid appears, and gradually heats up to 420°C. Keep until no lysis liquid flows out. Atmospheric distillation is carried out on the cracked liquid, and fractions at 90°C to 270°C are collected. Take 80g fraction and 5wt.% HZSM-5 (Si / Al=27) catalyst in a high-pressure reactor, start stirring, the reactor is heated to 350°C, react for 2h, and remove the catalyst by centrifugation. Take 40g of the product from the previous step and 5wt.% Pd / C catalyst in a high-pressure reactor, feed hydrogen gas at 4MPa, start stirring, heat the reactor to 200°C, and react for 4 hours to obtain a mixture containing alkanes, aromatic hydrocarbons and naphthenes , which is bio-aviation fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com