Preparation method of cationic fiber dyeable artificial leather

A technology for cationic fiber and artificial leather, which is applied in the field of preparation of cationic fiber dyeable artificial leather, can solve the problems of increased pressure of spinning components, high initial pressure of spinning, and increased viscosity of polyester, so as to reduce initial pressure and achieve bright colors. , The effect of suppressing the increase of filter pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

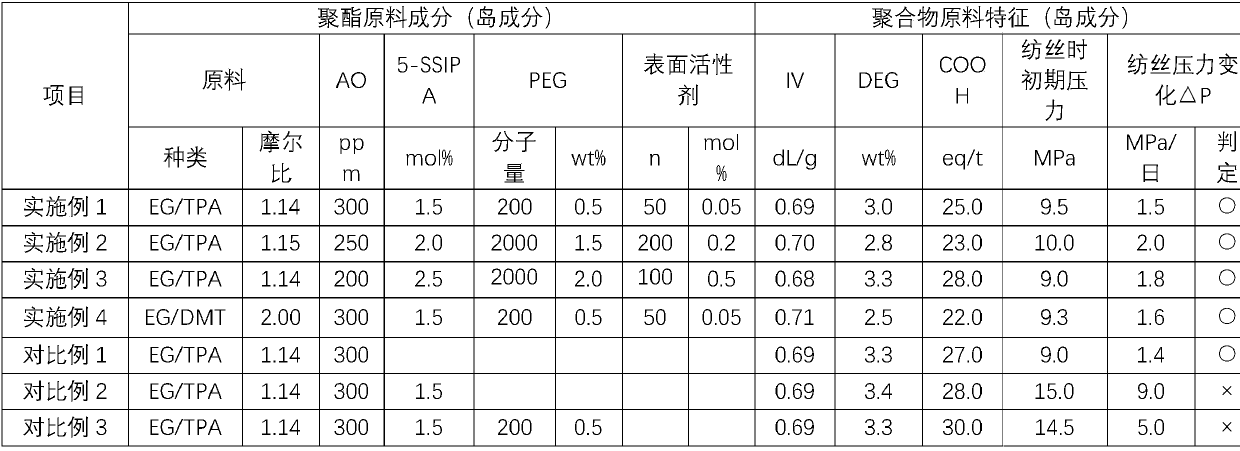

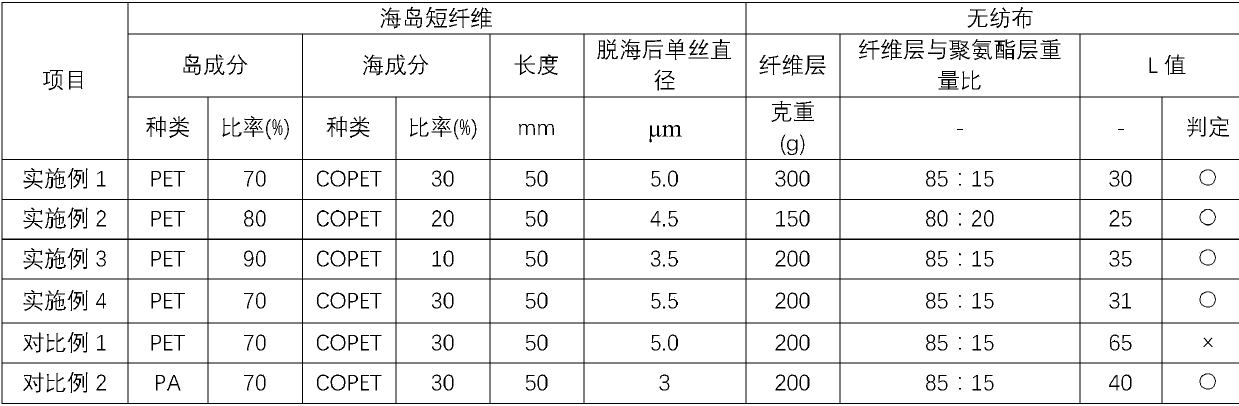

[0018] The preparation method of the cationic fiber dyeable artificial leather of the present invention comprises the following steps: (a) transferring the ethylene terephthalate oligomer to the polymerization reactor, adding polycondensation catalyst, isophthalic acid-5- Sodium sulfonate, Polyethylene Glycol and tensio-active agent react and make modified polyester; 1.0~3.0mol% of the dibasic acid), the content of the polyethylene glycol in the modified polyester is 0.5~2.0wt%; the general structural formula of the surfactant is (i.e. polydimethylsiloxane), whose content in the modified polyester is 0.03-0.6 mol% (relative to the dibasic acid that generates the modified polyester), and n is an integer of 50-1000; (b) using the modified polyester as the island component and alkali-soluble polyethylene terephthalate as the sea component to prepare island-fixed island-in-the-sea composite short fibers through a two-component spinning device; (c) the fixed island The island-sha...

Embodiment 1

[0022] The present embodiment provides a kind of preparation method of cationic fiber dyeable artificial leather, it comprises the following steps:

[0023] (a) Add ethylene glycol and dimethyl terephthalate (the molar ratio of the two is 2:1) to the reaction tank of the rectification tower, add cobalt acetate tetrahydrate as a transesterification catalyst, and conduct a transesterification reaction at 140°C , so that the obtained oligomer contains 500ppm of cobalt acetate tetrahydrate; then the temperature in the reaction tank is raised to 250°C, and the generated methanol is continuously rectified, and as the transesterification proceeds, terephthalic acid di Ethylene glycol ester until the transesterification reaction rate is 98%;

[0024] Add terephthalic acid and ethylene glycol in a molar ratio of 1:1.14 at 250°C to a reaction kettle (with a rectification tower) equipped with bottom material diethylene glycol terephthalate for esterification reaction. The esterification...

Embodiment 2

[0029] This embodiment provides a preparation method of cationic fiber dyeable artificial leather, which is basically the same as that in Example 1, except that the number of islands is 16, and the molar ratio of terephthalic acid to ethylene glycol is 1: 1.15, the addition of antimony trioxide is 250ppm, the addition of isophthalic acid-5-sodium sulfonate is 2.0mol%, the addition of PEG (molecular weight 2000) is 1.5wt%, surfactant (n=200 ) is added in an amount of 0.2 mol%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com