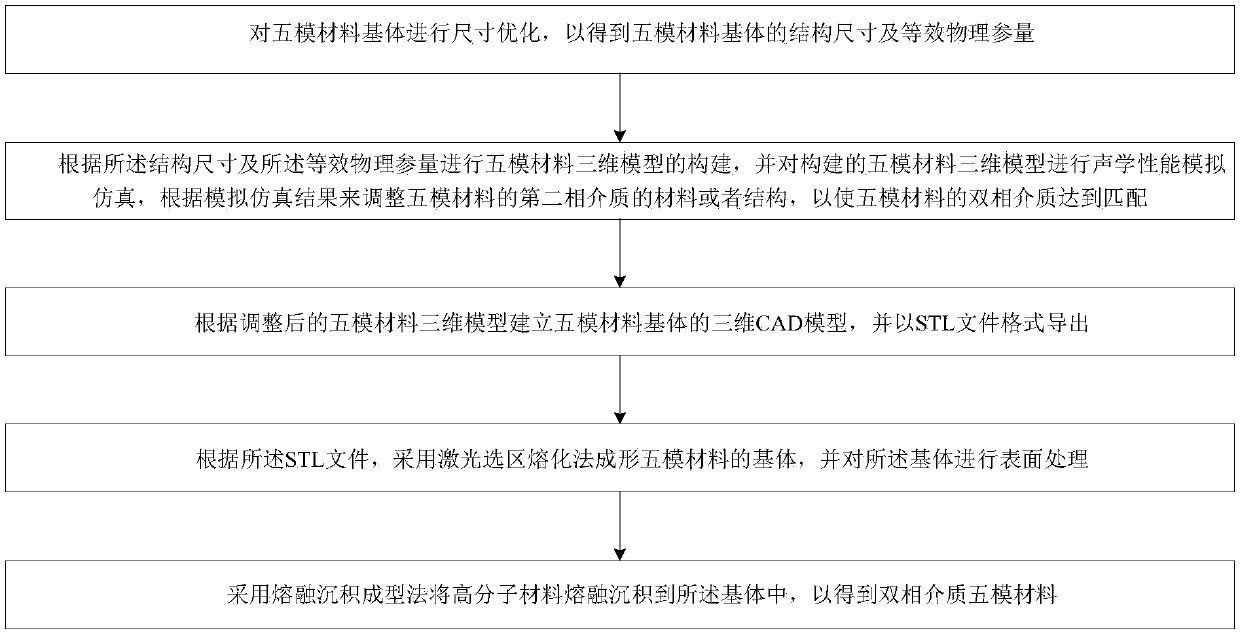

Two-phase medium pentamode material based on additive manufacturing and manufacturing method for two-phase medium pentamode material

A dual-phase medium, additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of limiting the acoustic and mechanical properties of five-mode materials, ineffectiveness, poor forming accuracy, etc., to achieve strong operability and applicability, Conducive to the promotion and application, the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

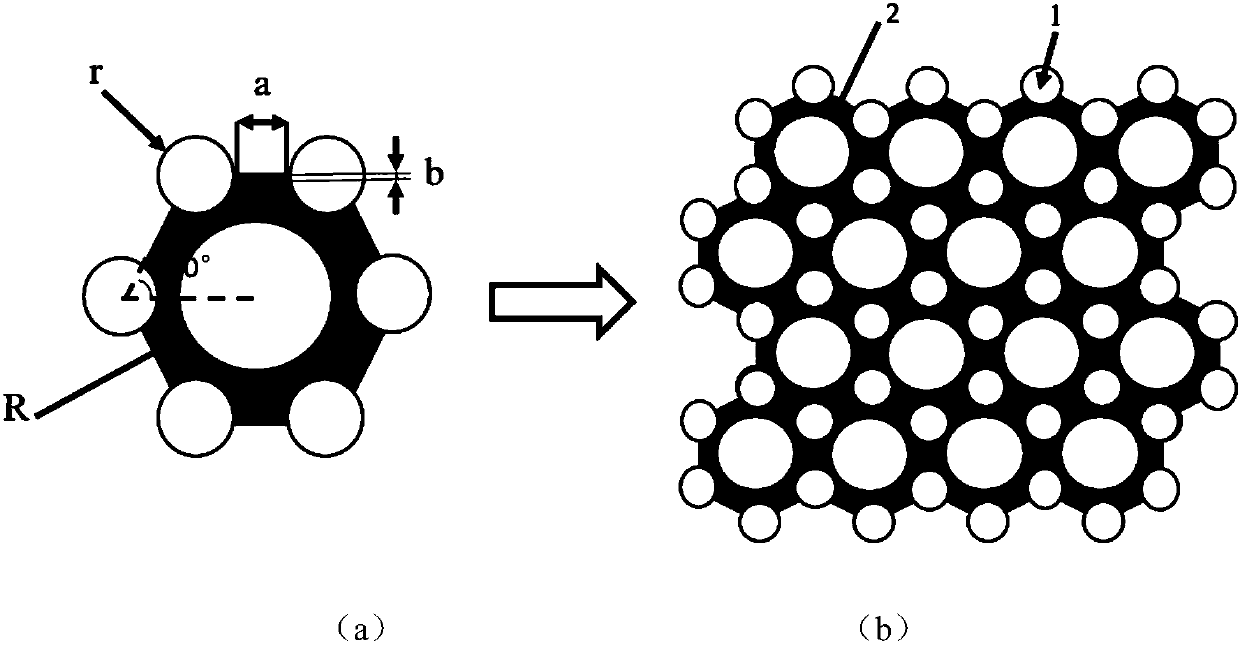

Embodiment 1

[0042] see figure 2 , The first embodiment of the present invention uses laser selective melting technology and fused deposition technology to prepare and shape titanium alloy / nylon dual-phase medium five-mode material. Ti 6 Al 4 V is a near-alpha titanium alloy, which is widely used in deep-sea equipment due to its ultra-high specific strength and excellent corrosion resistance; Ti 6 Al 4 As the matrix of five-mode materials, V can further improve the mechanical properties and corrosion resistance of functional materials, and due to the acoustic stealth performance of five-mode materials, it can make deep-sea equipment have good concealment when applied to the surface of equipment. In this example, the matrix adopts the evolution form of the honeycomb model, the nodes are circular, the radius is r, the length of the connecting rod is a, and the width is b. The second phase medium is nylon material with a melting point of 253°C. It is filled with the matrix structure so th...

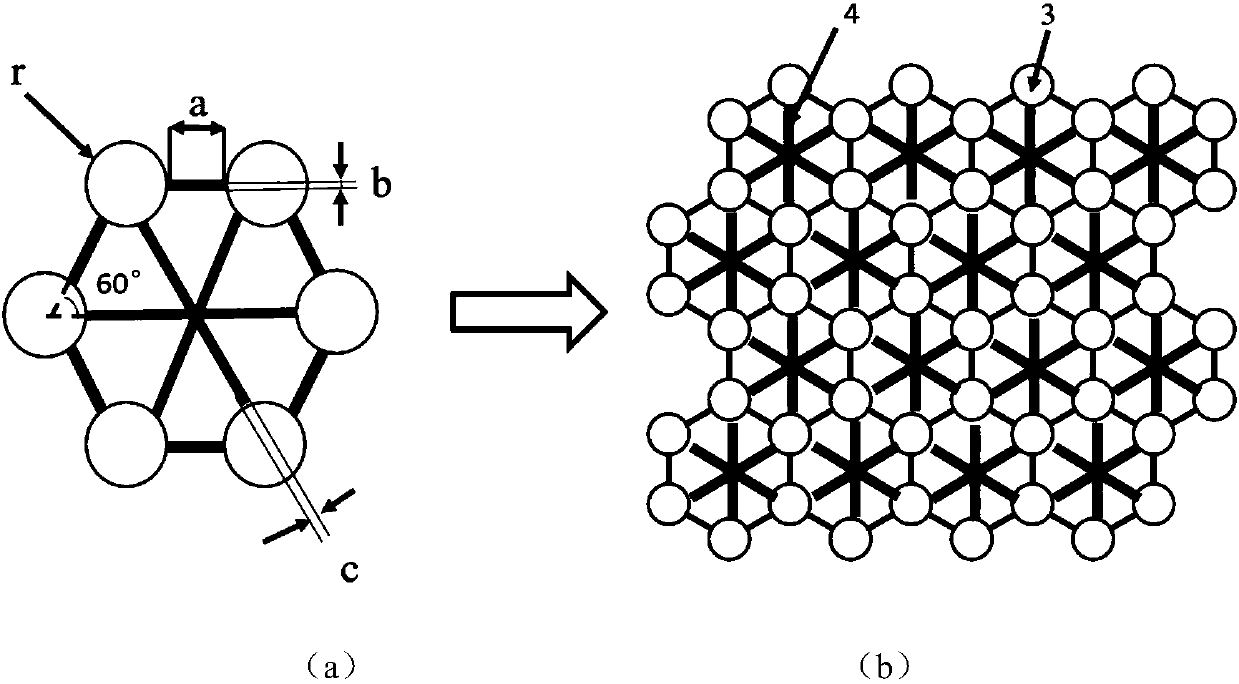

Embodiment 2

[0051] see image 3 , The second embodiment of the present invention uses laser selective melting technology and fused deposition technology to prepare and shape magnesium alloy / nylon dual-phase medium five-mode material. Among them, AlSi 10 Mg has good manufacturability, low density, and good corrosion resistance. It has good adaptability in the field of deep-sea equipment. The products formed by SLM process have good dimensional accuracy and surface quality, which ensures the accuracy of the formed size. In this example, the matrix adopts the evolution form of the honeycomb model, the nodes are circular, the radius is r, the length of the connecting rod is a, and the width is b. The second phase medium is nylon material with a melting point of 253°C. It is shaped by the matrix structure, and the structure presents a snowflake shape with width c. Under this condition, the second embodiment of the present invention produces AlSi 10 The main steps of the Mg / nylon dual-phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com