A kind of corona resistant polyimide composite film and preparation method thereof

A polyimide and composite film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of no obvious gain in electrical properties such as breakdown voltage of the composite film, and increase the overall thickness of the insulating structure and weight, the limited corona resistance of the composite film, etc., to increase the corona resistance time, shorten the preparation process flow, and have the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

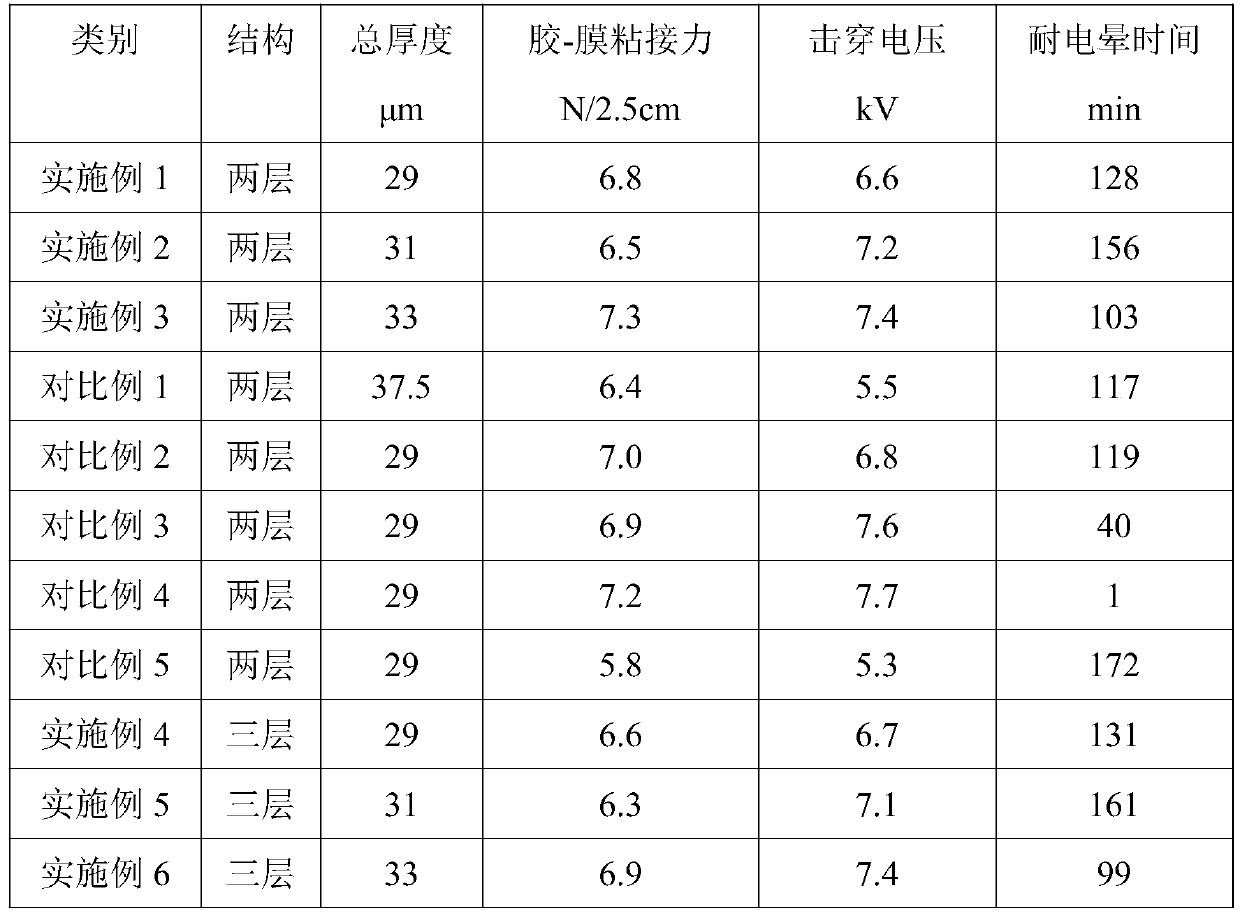

Embodiment 1

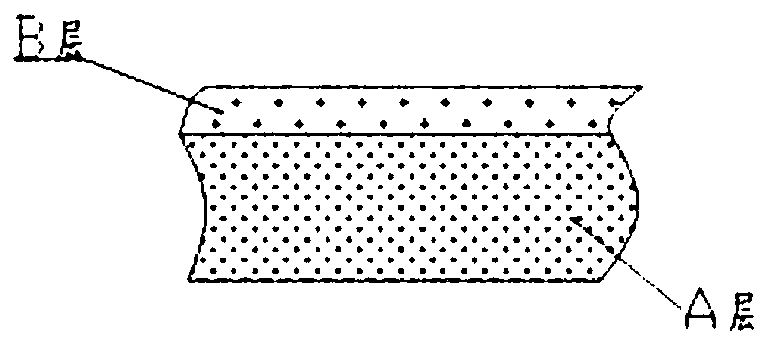

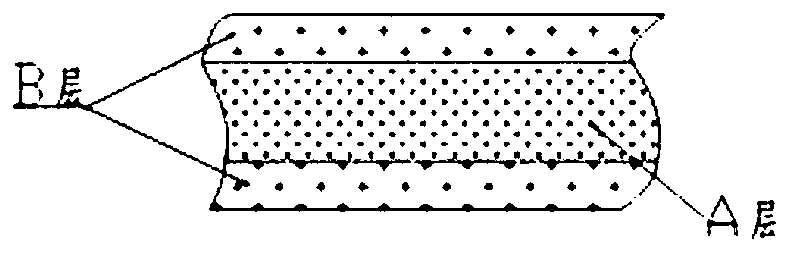

[0032] Such as figure 1 As shown, a corona-resistant polyimide composite film with a double-layer structure includes a thermosetting polyimide layer and a thermoplastic polyimide adhesive layer. The thickness of the thermosetting polyimide layer is 25 μm, and the thermosetting polyimide layer is prepared from the following materials: PMDA, 4,4'-ODA, DMAc, aluminum nitride (average particle size 30nm), aluminum nitride with nitride The aluminum nitride slurry is added in the form of aluminum nitride slurry to uniformly disperse aluminum nitride in DMAc, and at the same time, gamma-glycidoxypropyltrimethoxysilane is added to the slurry in order to improve the uniformity of dispersion.

[0033] The thickness of the thermoplastic polyimide adhesive layer is 4 μm, and the thermoplastic polyimide adhesive layer is prepared from the following substances: 2,2-bis[4-(4-aminophenoxy)phenyl]propane, 4,4' -(hexafluoroisopropyl) diphthalic dianhydride, DMAc, aluminum nitride (average part...

Embodiment 2

[0043] A double-layer corona-resistant polyimide composite film comprises a thermosetting polyimide layer and a thermoplastic polyimide adhesive layer. The thickness of the thermosetting polyimide layer is 25 μm, and the thermosetting polyimide layer is prepared from the following materials: BPDA, 3,4'-ODA, DMF, alumina (average particle size 150nm), alumina and alumina slurry Add in the form of alumina slurry to uniformly disperse alumina in DMF, and at the same time add aminopropyltriethoxysilane to the slurry in order to improve the uniformity of dispersion.

[0044] The thickness of the thermoplastic polyimide adhesive layer is 6 μm, and the thermoplastic polyimide adhesive layer is prepared from the following substances: 4,4'-(4,4'-isopropylidene diphenyl-1,1'-di Oxy)diphenylamine, 1,4-bis(trifluoromethyl)-2,3,5,6-benzenetetracarboxylic dianhydride, DMF, alumina (average particle size 150nm), alumina and alumina slurry Add in the form of alumina slurry to uniformly dispe...

Embodiment 3

[0054] A double-layer corona-resistant polyimide composite film comprises a thermosetting polyimide layer and a thermoplastic polyimide adhesive layer. The thickness of the thermosetting polyimide layer is 25 μm, and the thermosetting polyimide layer is prepared from the following materials: BTDA, 3,4'-ODA, NMP, boron nitride (average particle size 300nm), boron nitride is made of nitride Boron slurry is added in the form of boron nitride slurry, which is to disperse boron nitride in NMP evenly, and at the same time, aminopropyltriethoxysilane is added to the slurry in order to improve the uniformity of dispersion.

[0055] The thickness of the thermoplastic polyimide adhesive layer is 8 μm, and the thermoplastic polyimide adhesive layer is prepared from the following substances: 4,4'-(4,4'-isopropylidene diphenyl-1,1'-di Oxygen) diphenylamine, 1,4-difluoropyromellitic dianhydride, NMP, boron nitride (average particle size 300nm), boron nitride is added in the form of boron ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com