Nanometer porous NiFeMn alloy/oxide composite electrode and preparation method thereof

A technology of nanoporous nickel and iron-manganese alloys, which is applied in the field of preparing the above-mentioned electrodes and nanoporous nickel-iron-manganese alloy/oxide composite electrodes, and can solve the problems of poor conductivity, poor interfacial bonding force, and poor conductivity of transition metal oxides or hydroxides. Solve the problems of low capacity retention rate and achieve the effect of abundant raw materials, good electrical conductivity and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

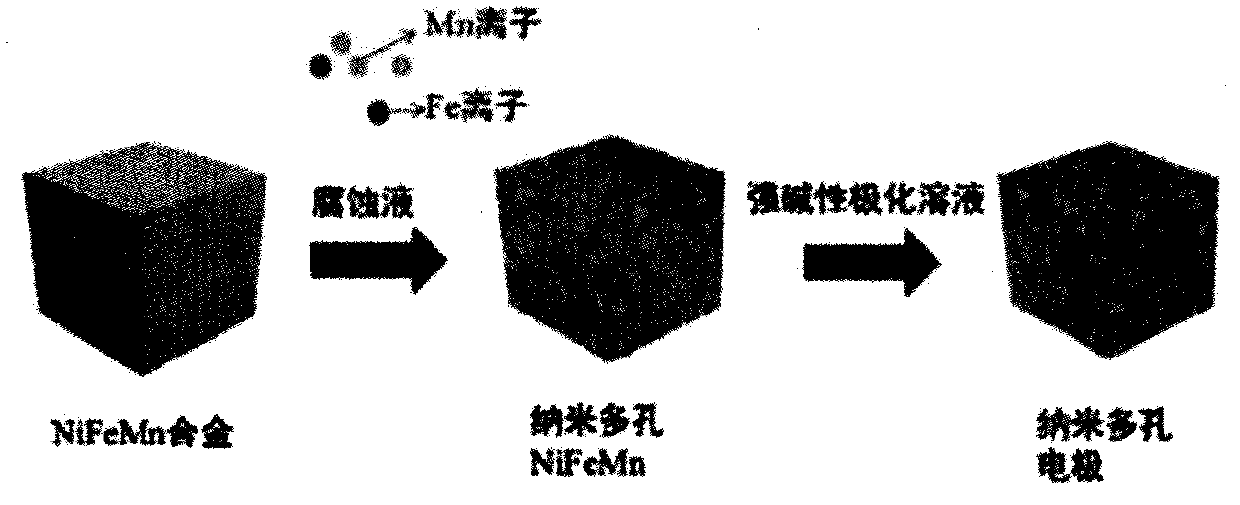

[0018] See figure 1 , the preparation method of the nanoporous nickel-iron-manganese alloy / oxide composite electrode that the present invention relates to, comprises the following steps:

[0019] (1) Preparation of the alloy: NiFeMn alloy is prepared, and its alloy composition ratio can be determined according to the ternary phase diagram to obtain a single-phase or few-phase solid solution. The preparation process includes strip spinning to prepare alloy strips and smelting and rolling to prepare alloy plates of different thicknesses. In order to ensure a continuous self-supporting electrode after subsequent dealloying and polarization processes, the content of manganese atoms in the alloy should be guaranteed to be 60% to 80%, the content of nickel atoms can be guaranteed to be between 5% and 25%, and the balance is Iron atoms (the ratios are all atomic content ratios).

[0020] (2) Preparation of nanoporous alloy; on the basis of step (1), selectively corrode part of the ...

Embodiment 1

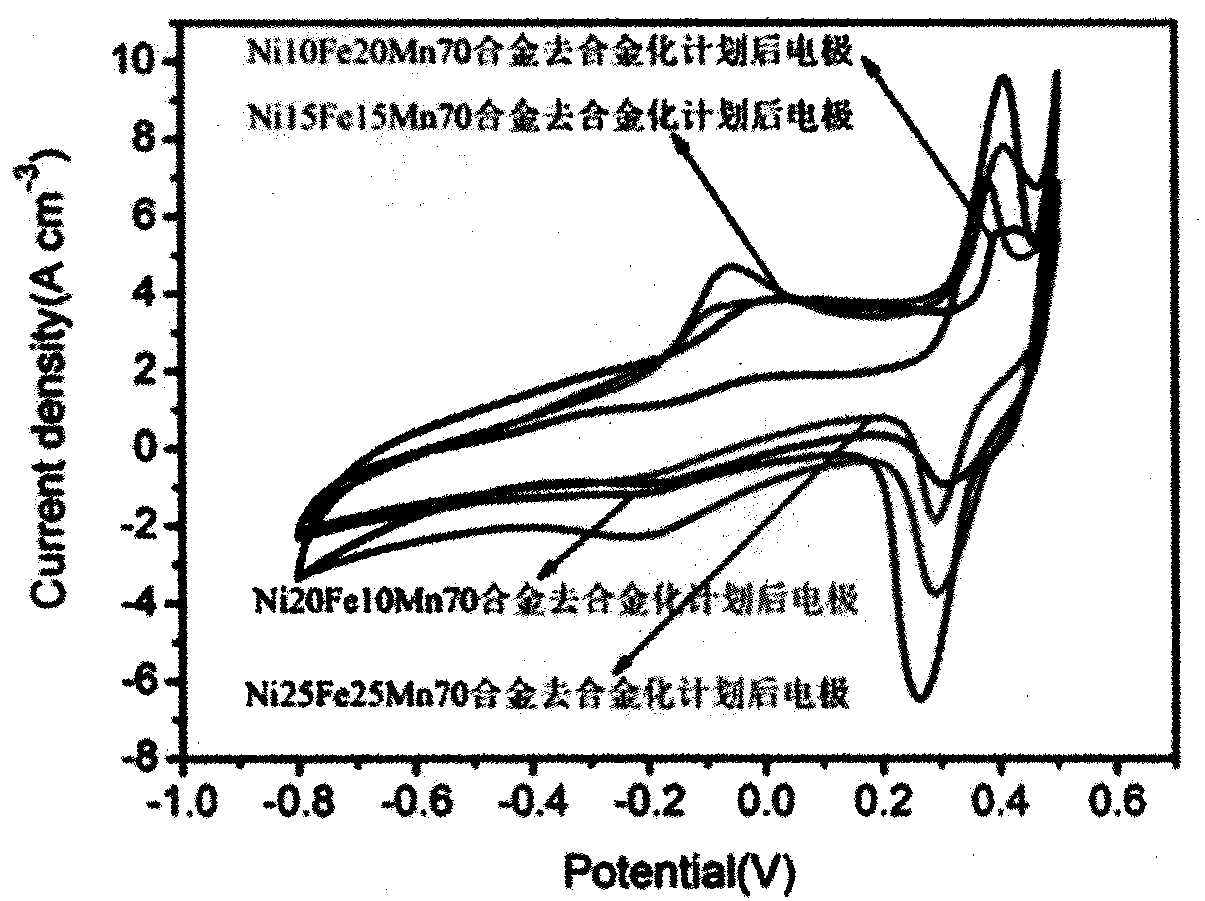

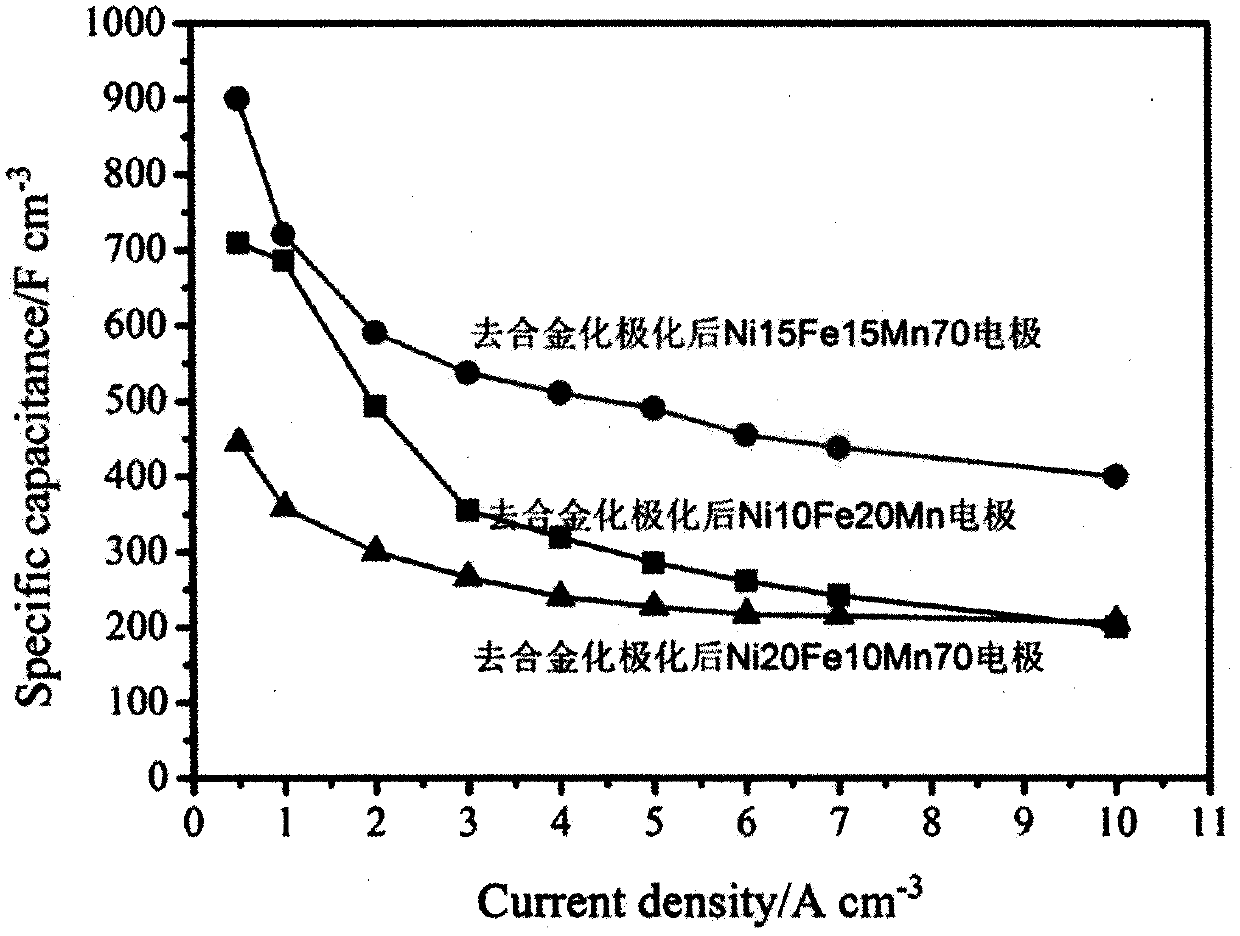

[0028] The Ni10Fe20Mn70 alloy with the alloy ratio was selected as the master alloy for three-electrode electrochemical dealloying in 1mol / L ammonium sulfate solution, the dealloying voltage was -0.65V, and the dealloying time was 1h. Potassium hydroxide of 1mol / L was used as the polarized electrolyte and the test electrolyte. After polarization, the test analysis found that: when the test voltage window was 1.3V, when the current density was 1A / cm 3 , the specific capacitance is 685F / cm 3 . The current density is 0.5-10A / cm 3 , the energy density can be maintained at 9.9-34mWh / cm 3 .

Embodiment 2

[0030] The Ni15Fe15Mn70 alloy with the alloy ratio was selected as the master alloy for three-electrode electrochemical dealloying in 1mol / L ammonium sulfate solution, the dealloying voltage was -0.65V, and the dealloying time was 1h. Potassium hydroxide of 1mol / L was used as the polarized electrolyte and the test electrolyte. After polarization, the test analysis found that: when the current density is 1A / cm 3 , the specific capacitance is 901F / cm 3 . The current density is 0.5-10A / cm 3 , the energy density can be maintained at 20-48mWh / cm 3 (voltage window 1.3V).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com