Scratch resistant paint vehicle for electric automobile chassis

A technology for electric vehicles and chassis, applied in the direction of coating, etc., can solve the problems of poor water resistance, poor wear resistance, poor adhesion, etc., and achieve the effects of stable anti-aging performance, strong wear resistance, and low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

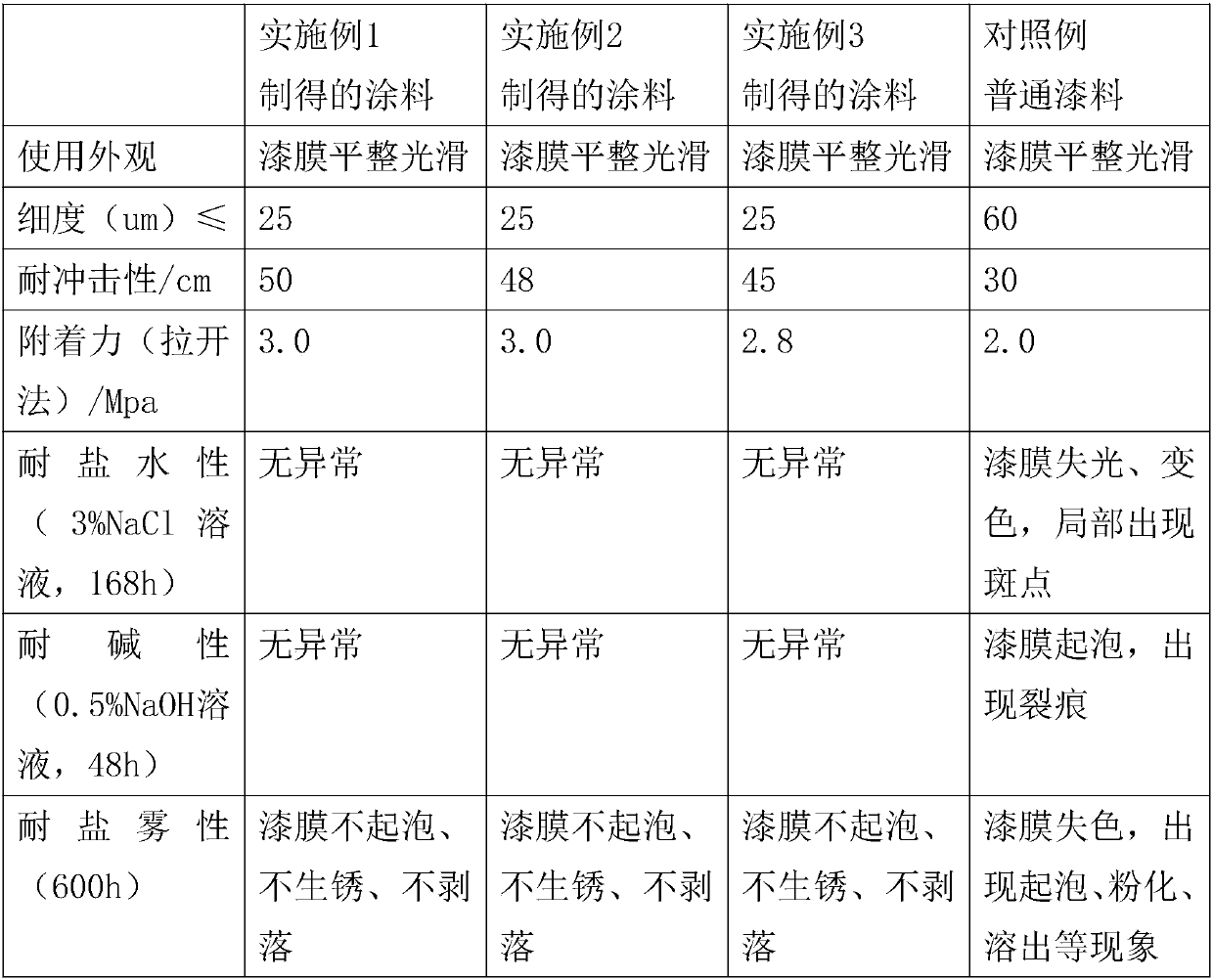

Examples

Embodiment 1

[0023] A scratch-resistant paint material for an electric vehicle chassis, prepared from the following raw materials: 60 parts by weight of phenylacrylic acid emulsion, 20 parts by weight of oily acrylic acid emulsion, 5 parts by weight of tetrabutylphosphine chloride, 15 parts by weight of xylene, propylene glycol methyl ether 5 parts by weight of acetate, 5 parts by weight of phytate, 5 parts of diallyl succinate, 1.5 parts of nano-graphene, 4 parts by weight of bismaleimide, 6 parts by weight of rosin, guar ether 6 parts by weight, 2.5 parts of trimethicone oil, 7 parts by weight of nano glass microspheres, 6 parts by weight of filler, 4 parts of diacetone alcohol, 1.5 parts by weight of surfactant, and 6 parts of antiseptic preparation.

[0024] The antiseptic preparation is made from the following raw materials in parts by weight: 2 parts of hirsutic acid bacteria, 1 part of cocoyl glucoside, 3 parts of polyhydroxypolyamine organic bases, 2 parts of sodium lauroyl ether su...

Embodiment 2

[0033] A scratch-resistant paint material for an electric vehicle chassis, prepared from the following raw materials: 40 parts by weight of phenylacrylic acid emulsion, 15 parts by weight of oily acrylic acid emulsion, 4 parts by weight of tetrabutylphosphine chloride, 10 parts by weight of xylene, propylene glycol methyl ether 4 parts by weight of acetate, 4 parts by weight of phytate, 4 parts of diallyl succinate, 1 part of nano-graphene, 3 parts by weight of bismaleimide, 5 parts by weight of rosin, guar gum ether 5 parts by weight, 2 parts by trimethicone, 5 parts by weight of nano glass microspheres, 5 parts by weight of filler, 2 parts by weight of diacetone alcohol, 0.5 parts by weight of surfactant, and 5 parts by weight of antiseptic preparation.

[0034] The antiseptic preparation is made from the following raw materials in parts by weight: 2 parts of hirsutic acid bacteria, 1 part of cocoyl glucoside, 3 parts of polyhydroxypolyamine organic bases, 2 parts of sodium l...

Embodiment 3

[0043] A scratch-resistant paint material for an electric vehicle chassis, prepared from the following raw materials: 40-80 parts by weight of phenylacrylic acid emulsion, 25 parts by weight of oily acrylic acid emulsion, 7 parts by weight of tetrabutylphosphine chloride, 20 parts by weight of xylene, propylene glycol 7 parts by weight of methyl ether acetate, 7 parts by weight of phytate, 6 parts of diallyl succinate, 2 parts of nano-graphene, 5 parts by weight of bismaleimide, 8 parts by weight of rosin, guar 7.5 parts by weight of gum ether, 3 parts by trimethicone, 10 parts by weight of nano glass microspheres, 7.5 parts by weight of filler, 5 parts by weight of diacetone alcohol, 2 parts by weight of surfactant, and 8 parts by weight of antiseptic preparation.

[0044] The antiseptic preparation is made from the following raw materials in parts by weight: 2 parts of hirsutic acid bacteria, 1 part of cocoyl glucoside, 3 parts of polyhydroxypolyamine organic bases, 2 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com