Micro-electrolysis treatment process for furfural wastewater

A treatment process and micro-electrolysis technology, applied in water/sewage treatment, natural water treatment, biological water/sewage treatment, etc., can solve the problems of furfural wastewater not being effectively treated, water environment pollution, etc. Energy saving and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A furfural factory uses corncobs as raw materials and heats them at high temperature in the presence of a catalyst to hydrolyze polypentoses into pentoses and dehydrate the pentoses to furfural. The waste water in the production process mainly comes from tower bottom waste water, neutralization waste water, vacuum distillation waste water, brush tank and brush bucket waste water and other waste water, etc. The concentration of organic pollutants in the waste water is high, the acidity is strong, and the pH range is between 1.80-2.81 During the period, the average B / C value was 0.42.

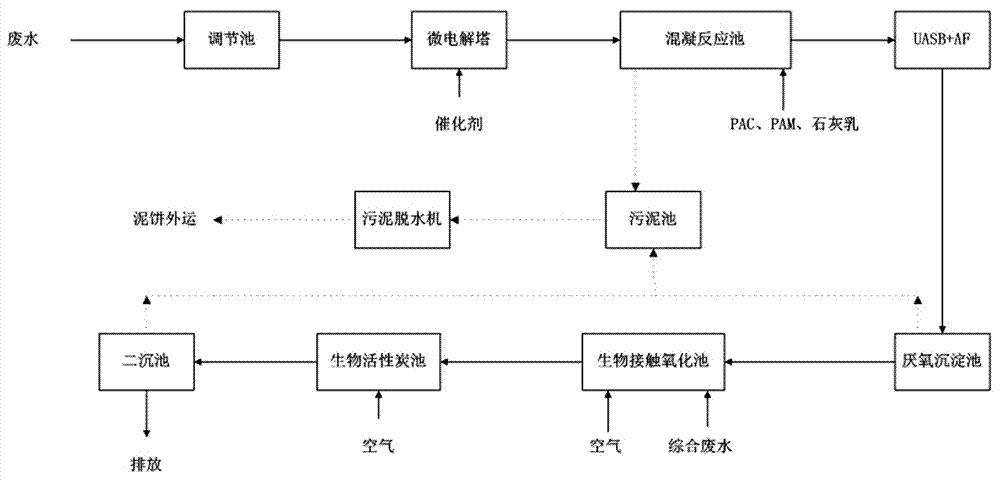

[0030] like figure 1 A kind of furfural wastewater treatment process shown, carries out according to the following steps:

[0031] (1) Wastewater pretreatment

[0032] A. Regulating treatment: the production wastewater enters the regulating tank, stays for 10 hours, lowers the water temperature, and after the water quality is uniform, it is pumped to the micro-electrolysis tower;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com