Metronidazole synthesizing device and metronidazole synthesizing method applying same

A synthesis device and synthesis method technology, applied in the direction of organic chemistry, etc., to achieve the effects of less investment in equipment, ensuring continuity, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

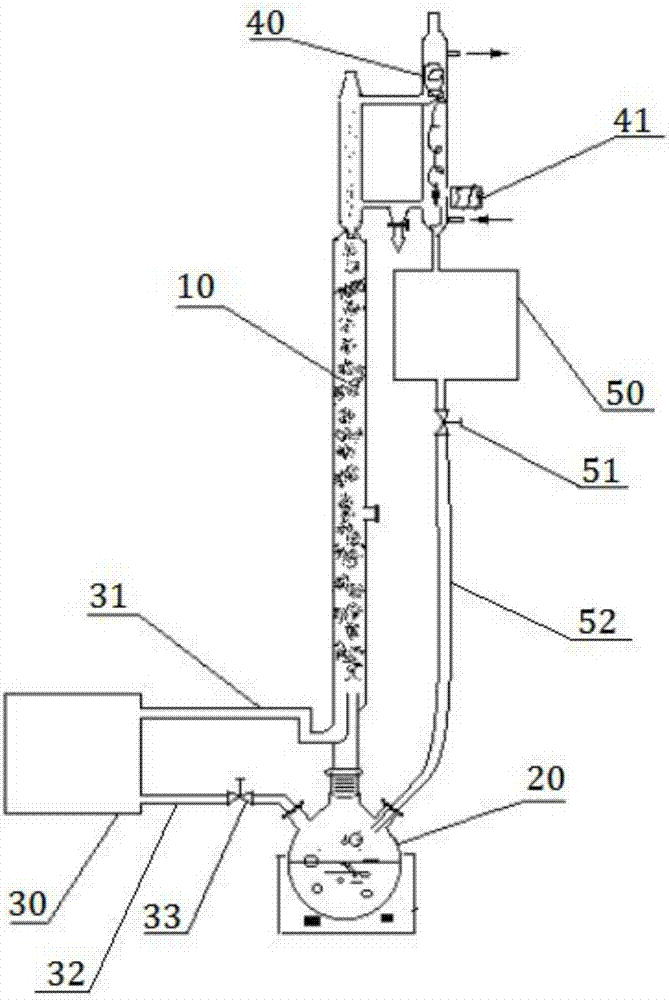

[0041] Step 1): open the light component reflux valve (52), close the heavy component reflux valve (33), and add lower carbon alcohol formate, ethylene glycol and 2-methyl-5-nitroimidazole in the reaction kettle (20) , stir, add dropwise 85% formic acid, carry out transesterification to generate lower carbon alcohol and ethylene glycol formate, heat distillation, steam enters rectification column (10) rectification separation, wherein the formic acid lower alcohol ester of light component is from refined The rectification steam discharge port on the top of the distillation tower (10) is refluxed to the reactor (20) through the condenser (40) and the ester storage tank (50); The distillate outlet flows into the alcohol storage tank (30);

[0042] Step 2): When the temperature of the reactor (20) rises to the boiling point of the low-carbon alcohol, close the light component reflux valve (52), and when the temperature of the reactor (20) rises to above the boiling point of the l...

Embodiment 2

[0051] Step 1): open the light component reflux valve (52), close the heavy component reflux valve (33), and add lower carbon alcohol formate, ethylene glycol and 2-methyl-5-nitroimidazole in the reaction kettle (20) , stir, add the concentrated sulfuric acid dropwise, carry out transesterification reaction and generate lower carbon alcohol and ethylene glycol formate, heat distillation, steam enters rectification column (10) rectification separation, wherein the lower carbon alcohol ester of formic acid of light component from rectification The rectification steam discharge port on the upper part of the tower (10) passes through the condenser (40) and the ester storage tank (50), and then flows back to the reactor (20); The liquid outlet flows into the alcohol storage tank (30);

[0052] Step 2): When the temperature of the reactor (20) rises to the boiling point of the low-carbon alcohol, close the light component reflux valve (52), and when the temperature of the reactor (2...

Embodiment 3

[0061] Step 1): open the light component reflux valve (52), close the heavy component reflux valve (33), and add lower carbon alcohol formate, ethylene glycol and 2-methyl-5-nitroimidazole in the reaction kettle (20) , stir, add dropwise 98% vitriol oil, carry out transesterification to generate lower carbon alcohol and ethylene glycol formate, heat distillation, steam enters rectification tower (10) rectification separation, wherein the formic acid lower alcohol ester of light component from The rectification steam discharge port on the top of the rectification tower (10) is refluxed to the reactor (20) through the condenser (40) and the ester storage tank (50); The rectifying liquid outlet flows into the alcohol storage tank (30);

[0062] Step 2): When the temperature of the reactor (20) rises to the boiling point of the low-carbon alcohol, close the light component reflux valve (52), and when the temperature of the reactor (20) rises to above the boiling point of the low-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com