Hydrogel with controllable mechanical properties and swelling ratio as well as preparation method and application thereof

A swelling rate and hydrogel technology, applied in the field of hydrogel and its preparation, can solve problems such as weak electrostatic interaction chemical crosslinking, toxic chemical crosslinking agents, increased mechanical properties and swelling rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

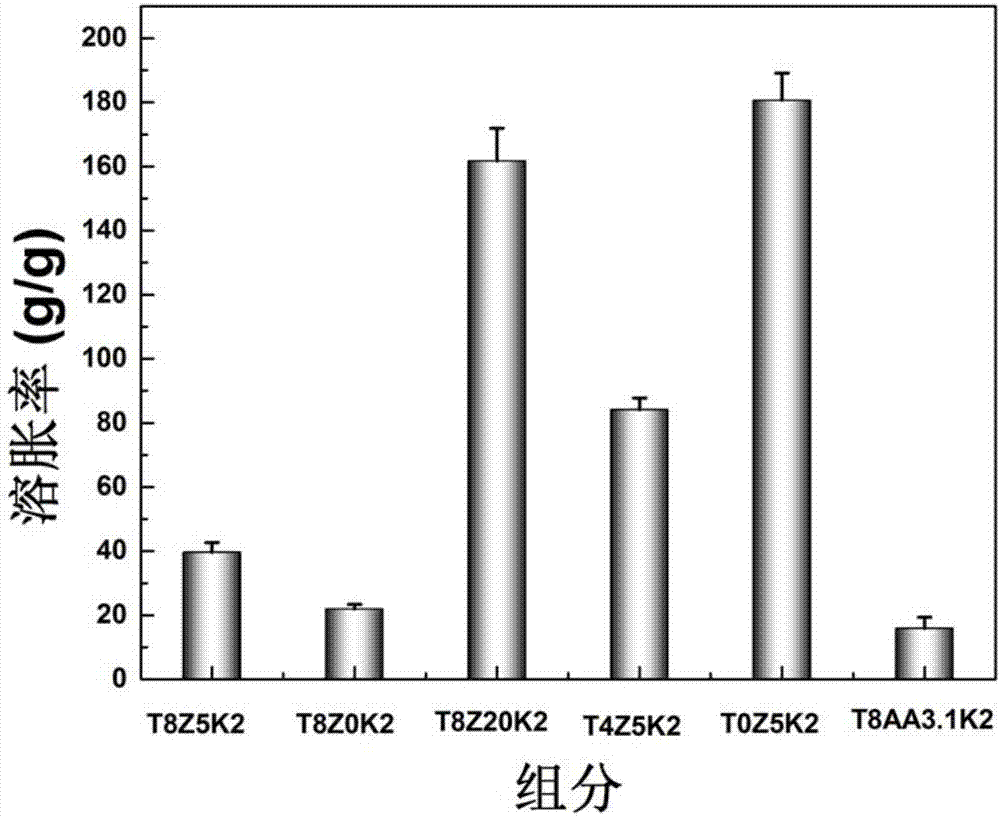

[0024] The concentration of 1g acrylamide monomer (Sinopharm Chemical Reagent Company), sulfuric acid hydrolyzed concentration is 3.144wt% ascidian cellulose nanocrystal aqueous dispersion 2.6g, zinc methacrylate (Aladdin Reagent Company) 0.05g and concentration is 4wt% Initiator potassium persulfate (Sinopharm Chemical Reagent Company) aqueous solution 0.5g, under the environment of 60 ℃, thermally initiates polymerization 48h reaction and generates hydrogel (containing ascidian cellulose nanocrystal 8wt% relative to monomer content in the hydrogel, Zinc methacrylate 5wt%, named T8Z5K2), and then soaked in deionized water at room temperature for 72h to reach swelling equilibrium.

[0025] The swelling rate is measured by gravimetric analysis, and the swelling rate (SR) is calculated by the formula Calculate, where W e and W d represent the weight of the hydrogel and the weight of the xerogel at equilibrium, respectively.

[0026] At room temperature, use a universal mater...

Embodiment 2

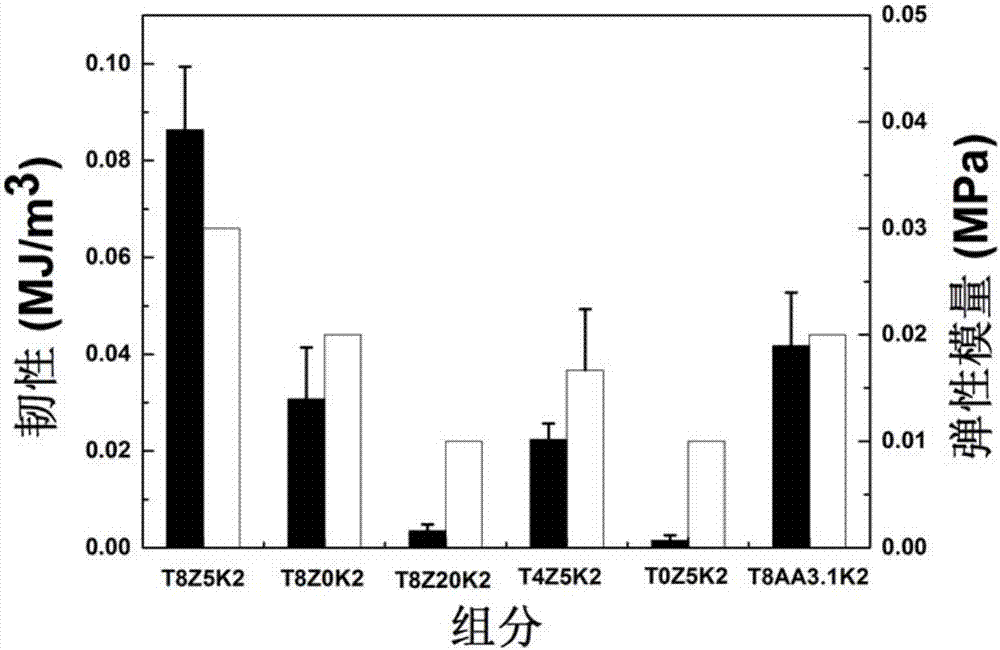

[0029] The concentration of 1g of acrylamide monomer, sulfuric acid hydrolyzed concentration is 3.144wt% sea squirt cellulose nanocrystal aqueous dispersion liquid 2.6g, zinc methacrylate 0g and concentration are 4wt% initiator potassium persulfate aqueous solution 0.5g, at 60 ℃ Under the environment of thermal initiation polymerization 48h reaction generates hydrogel (containing ascidian cellulose nanocrystal 8wt% relative to the monomer content in the hydrogel, zinc methacrylate 0wt%, named after T8Z0K2), then at room temperature Soak in deionized water for 72h to reach swelling equilibrium. tested as figure 1 and figure 2 As shown, the swelling rate of the resulting hydrogel with swelling balance is 22g / g, and the toughness is 30.71kJ / m 3 , the modulus of elasticity is 20kPa.

Embodiment 3

[0031] The concentration of 1g of acrylamide monomer, sulfuric acid hydrolyzed concentration is 3.144wt% ascidian cellulose nanocrystal aqueous dispersion liquid 2.6g, zinc methacrylate 0.2g and concentration are 0.5g of the initiator potassium persulfate aqueous solution of 4wt%, at 60 Under the environment of ℃, thermally initiate polymerization for 48h to generate hydrogel (containing ascidian cellulose nanocrystal 8wt% relative to the monomer content, 20wt% zinc methacrylate, named as T8Z20K2) in the hydrogel, and then at room temperature Soak in deionized water for 72h to reach swelling equilibrium. tested as figure 1 and figure 2 As shown, the swelling ratio of the hydrogel with swelling balance obtained is 161g / g, and the toughness is 3.48kJ / m 3 , the modulus of elasticity is 10kPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| toughness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com