Low-density and flexible polymer-based foaming and sound insulating material and preparation method thereof

A technology of flexible polymer and sound insulation material, which is applied in the field of low density, flexible polymer-based foamed sound insulation material and its preparation, can solve the problems that polymer-based sound insulation materials cannot have both, low density, etc., and achieves good performance. Flexibility, low density, the effect of improving sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mix polyvinyl chloride (100 parts) with stabilizer (4.5 parts), plasticizer (60 parts), processing aid (4 parts), azodicarbonamide blowing agent (1%), mica (10%) Mix in a high-speed mixer at 90°C for 20 minutes, so that the plasticizer is completely absorbed to obtain a polyvinyl chloride dry mix. The dry blend was mixed and plasticized on a two-roll mill at 140°C for 10 minutes. Fill the mold with a thickness of 2 mm with the obtained mixed plastic compound, and foam molding in a pressure molding machine for 10 minutes at a temperature of 180 ° C and a pressure of 10 MPa.

[0026] The low-density, flexible foam sound insulation material that present embodiment prepares, density is 0.45g / cm 3 , expansion ratio 2.8, cell density 1.1×10 7 piece / cm 3 , the average cell size is 60 μm, the hardness is 35, and the average sound insulation of the material is 32 dB.

Embodiment 2

[0028] Roll the EPDM rubber (100 parts) on a two-roll mill to form a sheet, and then successively add zinc oxide (5 parts), stearic acid (0.5 parts), vulcanizing agent peroxidation and cumene (1 part ), expanded microspheres (5%), reinforcing carbon black (20 parts), and boron nitride (5%) were added to the rubber, and the fillers, additives and rubber matrix were mixed evenly by packing and tumbling, and mixed for 20 After 10 minutes, the mixed rubber is thinly passed out of the sheet, and the temperature of the two-roller mill is 90°C. Fill the mold with a thickness of 2 mm with the mixed rubber, and vulcanize and foam in a flat vulcanizer for 10 minutes at a temperature of 160°C and a pressure of 15 MPa.

[0029] The low-density, flexible foam sound insulation material prepared in this example has a density of 0.32 g / cm 3 , expansion ratio 3.3, cell density 1.5×10 7 piece / cm 3, the average cell size is 50 μm, the hardness is 30, and the average sound insulation of the ma...

Embodiment 3

[0031] Mix polyvinyl chloride (100 parts) with stabilizer (4.5 parts), plasticizer (50 parts), processing aid (4 parts), azodicarbonamide blowing agent (2%), mica (5%) , Boron nitride (5%) was mixed in a high-speed mixer at 90°C for 20 minutes, so that the plasticizer was completely absorbed, and a polyvinyl chloride dry mix was obtained. The dry blend was mixed and plasticized on a two-roll mill at 140°C for 10 minutes. The obtained mixed plastic material is pelletized and put into a single-screw extruder for extrusion and foaming. The temperature of each section of the extruder is: 120°C, 140°C, 180°C, 180°C, and the die is 170°C. °C.

[0032] The foamed sound insulation material prepared in this example has a density of 0.30 g / cm 3 , expansion ratio 4.1, cell density 8.5×10 6 piece / cm 3 , the average cell size is 90 μm, the hardness is 38, and the average sound insulation is 34 dB.

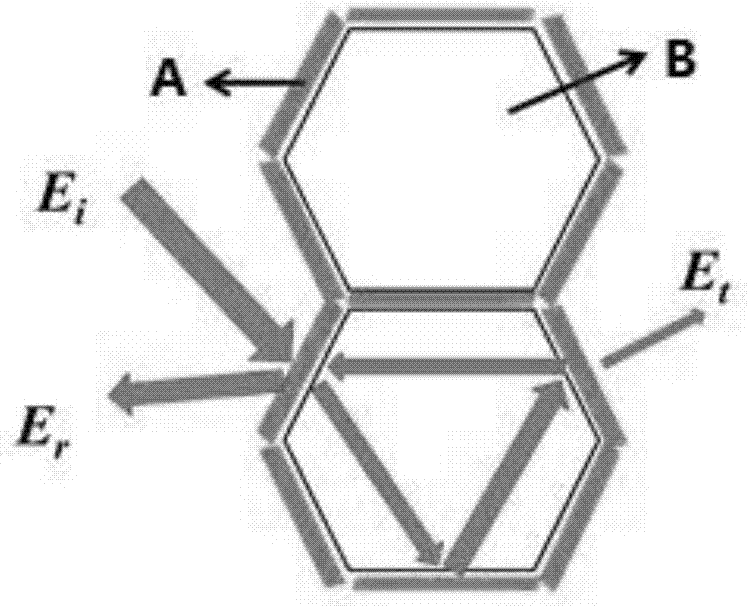

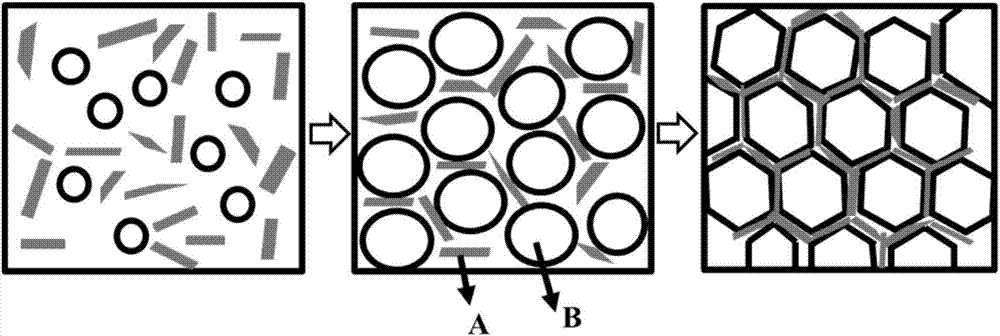

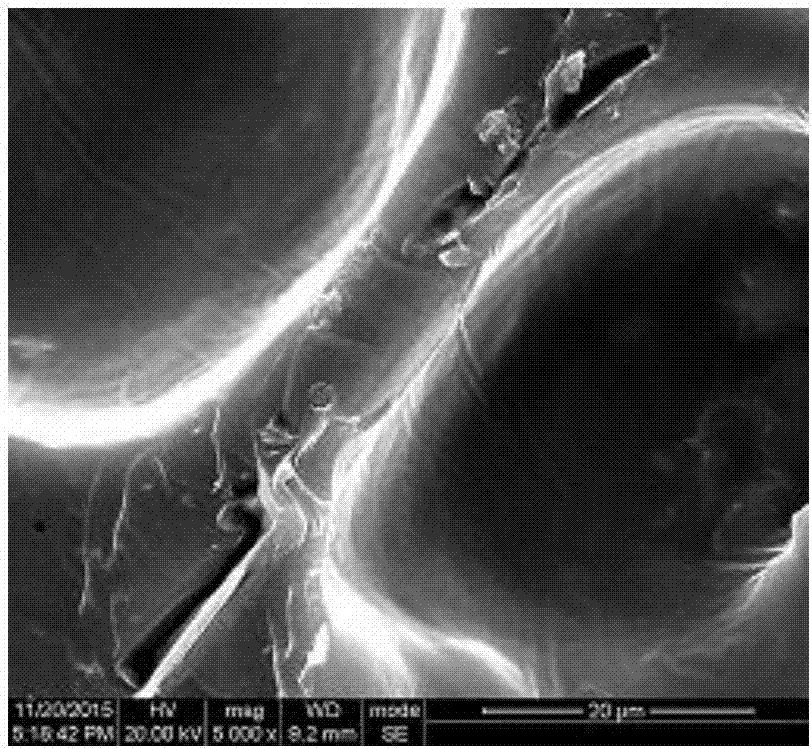

[0033] In order to show more clearly that the present invention utilizes the special s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average sound insulation | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com