Optimum design method of jet type self-absorbing centrifugal pump

An optimized design and centrifugal pump technology, applied in the research field of centrifugal pumps, can solve the problems of unable to increase the lift at the dead point, disk friction loss, large inlet loss, etc., to reduce disk friction loss, reduce inlet impact loss, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

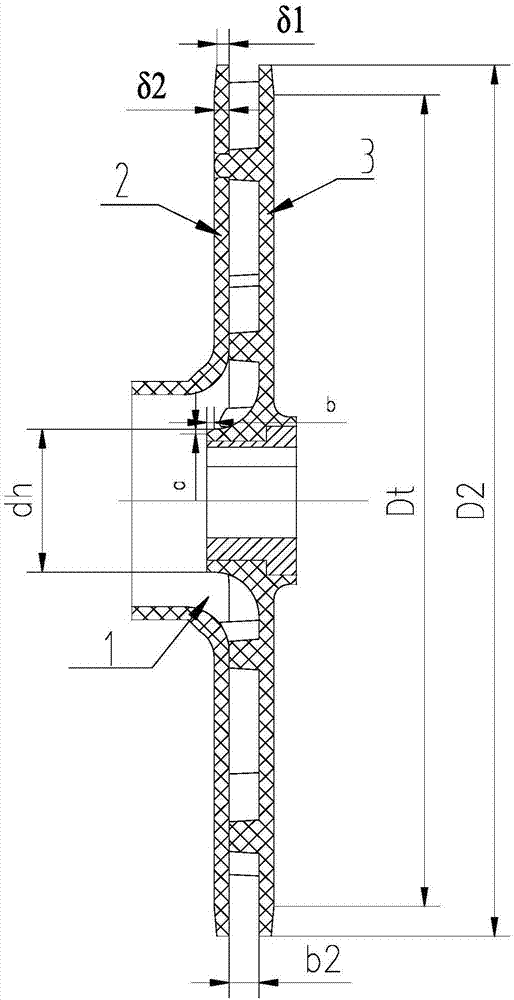

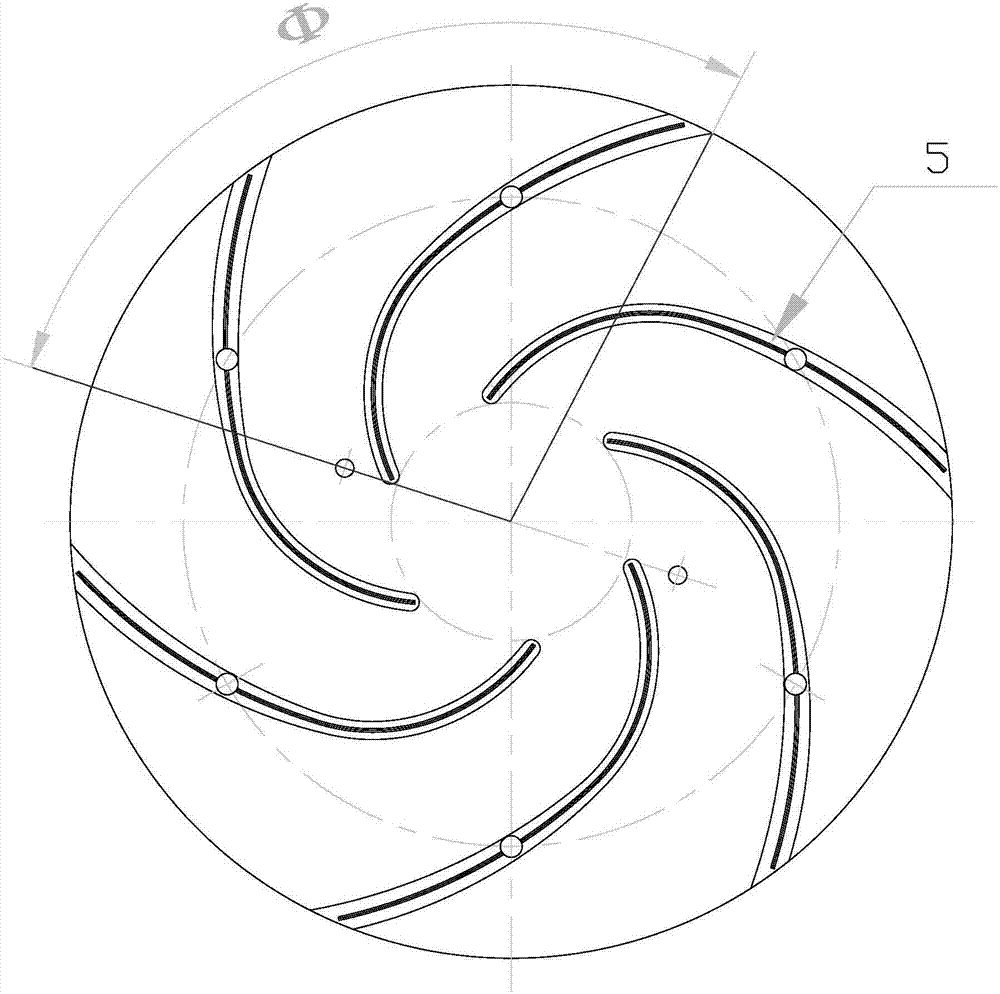

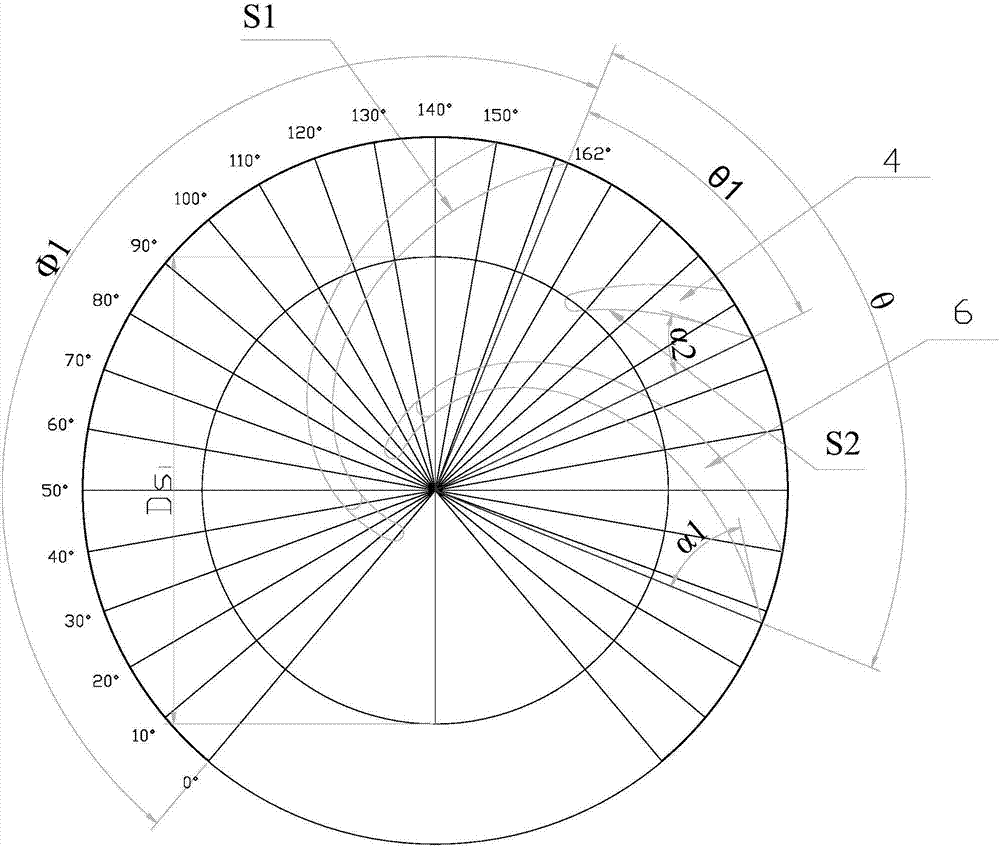

[0057] The optimization design method of a jet type self-priming centrifugal pump of the present invention includes optimizing the impeller inlet 1, the impeller front cover 2, the impeller rear cover 3 and the impeller blades.

[0058] The impeller inlet is optimized. When the liquid passes through the impeller inlet side, it will produce impact, which will cause impact loss. In order to reduce the loss, the invention cuts the impeller inlet side to make it a buffer zone, so that the liquid flows through this The loss during processing is much smaller, which can achieve the effect of reducing the impact loss of imports very well.

[0059] In order to make the impeller inlet edge become the desired buffer zone, the cutting scheme adopted by the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com