Preparation method of ferric sulfide modified sludge-based biochar

A technology of iron sulfide and biochar, which is applied in the field of biomass resource utilization, can solve the problems of waste of resources and a large amount of funds, and achieve the effects of simple production process, realization of degradation and removal, good economic value and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

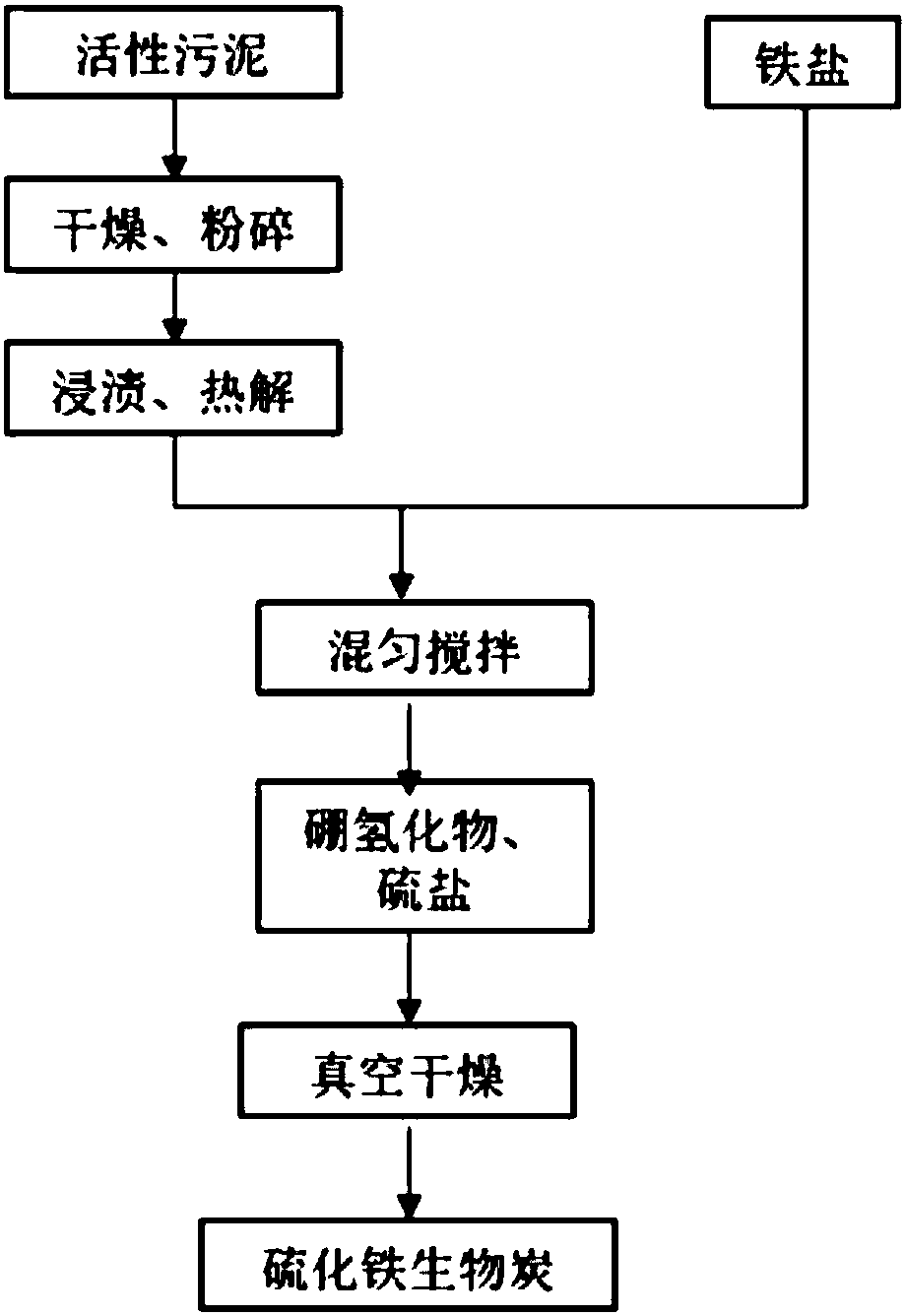

[0031] Such as figure 1 Shown flow chart, a kind of method utilizing sludge to prepare nano iron sulfide modified biochar of the present invention, concrete steps are as follows:

[0032] (1) After the sludge is dried and pulverized to 20 meshes, take 100 g of the powder, add the sludge powder to 500 mL of sodium carbonate solution with a mass concentration of 10%, stir well, then soak for 4 hours at room temperature, discard the remaining After liquid, dry for later use;

[0033] (2) Place the above powder in the atmosphere furnace, set the temperature of the atmosphere furnace to 400°C, the heating rate is 15°C / min, keep it warm for 2 hours, and take it out after naturally cooling to room temperature;

[0034] (3) Mix 100g of the sludge obtained from the above treatment with a ferric chloride solution with a concentration of 0.20mol / L and a volume of 200mL. The immersion temperature is controlled at 20°C and the immersion time is 4h to ensure sufficient immersion. After imm...

Embodiment 2

[0040] A method of utilizing sludge to prepare nano-iron sulfide modified biochar of the present invention, the specific method steps are as follows:

[0041] (1) After the sludge is dried and pulverized to 60 mesh, take 100g of the powder, add the sludge powder to 800mL of sodium carbonate solution with a mass concentration of 10%, stir well, then immerse at room temperature for 8h, discard After remaining liquid, dry it for later use;

[0042] (2) Place the above powder in an atmosphere furnace, set the temperature of the atmosphere furnace at 600°C, heat up at a rate of 20°C / min, keep it warm for 3 hours, and take it out after naturally cooling to room temperature;

[0043] (3) Mix 100g of the sludge obtained from the above treatment with a ferric chloride solution with a concentration of 0.40mol / L and a volume of 500mL. The immersion temperature is controlled at 30°C and the immersion time is 6h to ensure sufficient immersion. After immersion, use processed in the next step...

Embodiment 3

[0050] A method of utilizing sludge to prepare nano-iron sulfide modified biochar of the present invention, the specific method steps are as follows:

[0051] (1) After the sludge is dried and pulverized to 60 meshes, take 100 g of the powder, add the sludge powder to 800 mL of sodium carbonate solution with a mass concentration of 10%, stir well, then soak at room temperature for 10 h, discard the remaining After liquid, dry for later use;

[0052] (2) Place the above powder in the atmosphere furnace, set the temperature of the atmosphere furnace at 700°C, and the heating rate is 25°C / min, keep it for 4 hours, and take it out after naturally cooling to room temperature;

[0053] (3) Mix 10 g of the sludge obtained from the above treatment with a ferrous sulfate solution with a concentration of 0.80 mol / L and a volume of 100 mL. The immersion temperature is controlled at 35 ° C, and the immersion time is 12 hours to ensure sufficient immersion. After immersion, it is used nex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com