Preparation method of fibroin-cellulose nano composite mask

A silk protein and nano-composite technology, which can be used in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulations, etc., and can solve problems such as poor toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

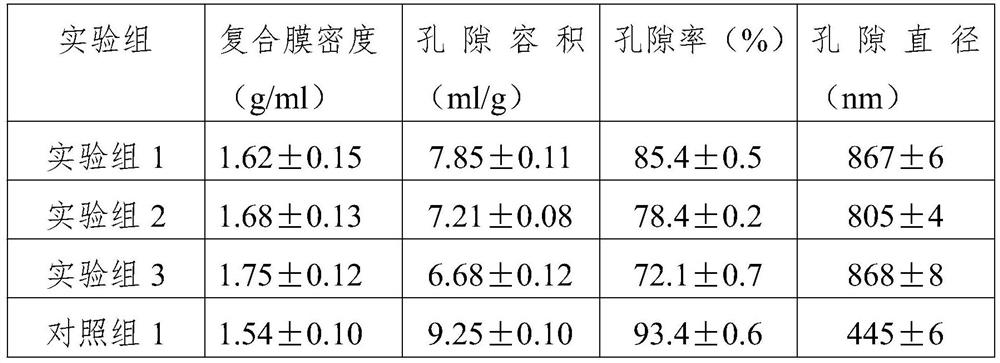

Embodiment 1

[0017] A preparation method of silk protein-cellulose nanocomposite facial mask, the steps are as follows:

[0018] (1) Culture medium preparation: ultrafinely pulverize defatted corn germ and sieve; dissolve defatted corn germ powder in sodium bicarbonate solution, add alkaline protease (Protext 6L) for enzymatic hydrolysis, and inactivate enzyme; add glucose, yeast soak powder; adjust the pH to 4.5; centrifuge; filter; high temperature instantaneous sterilization. (2) Inoculation of Kombucha; (3) Fermentation; (4) NaOH solution dissolves bacterial cellulose to prepare pure cellulose film, and high-voltage electrostatic spraying method applies silk protein solution on the pure cellulose film to prepare silk protein-cellulose nano Composite mask.

[0019] Preferably, the liquid culture medium is prepared by: superfinely pulverizing defatted corn germ, passing through a 600-mesh sieve; dissolving defatted corn germ powder in sodium bicarbonate solution, wherein the mass ratio ...

Embodiment 2

[0024] A preparation method of silk protein-cellulose nanocomposite facial mask, the steps are as follows:

[0025] (1) Culture medium preparation: ultrafinely pulverize defatted corn germ and sieve; dissolve defatted corn germ powder in sodium bicarbonate solution, add alkaline protease (Protext 6L) for enzymatic hydrolysis, and inactivate enzyme; add glucose, yeast soak powder; adjust the pH to 5.0; centrifuge; filter; high temperature instantaneous sterilization. (2) Inoculation of Kombucha; (3) Fermentation; (4) NaOH solution dissolves bacterial cellulose to prepare pure cellulose film, and high-voltage electrostatic spraying method applies silk protein solution on the pure cellulose film to prepare silk protein-cellulose nano Composite mask.

[0026] Preferably, the liquid culture medium is prepared by: superfinely pulverizing defatted corn germ, passing through a 700-mesh sieve; dissolving defatted corn germ powder in sodium bicarbonate solution, wherein the mass ratio ...

Embodiment 3

[0031] A preparation method of silk protein-cellulose nanocomposite facial mask, the steps are as follows:

[0032] (1) Culture medium preparation: ultrafinely pulverize defatted corn germ and sieve; dissolve defatted corn germ powder in sodium bicarbonate solution, add alkaline protease (Protext 6L) for enzymatic hydrolysis, and inactivate enzyme; add glucose, yeast soak powder; adjust the pH to 5.5; centrifuge; filter; high temperature instantaneous sterilization. (2) Inoculation of Kombucha; (3) Fermentation; (4) NaOH solution dissolves bacterial cellulose to prepare pure cellulose film, and high-voltage electrostatic spraying method applies silk protein solution on the pure cellulose film to prepare silk protein-cellulose nano Composite mask.

[0033]Preferably, the liquid culture medium is prepared by: superfinely pulverizing defatted corn germ, passing through a 800-mesh sieve; dissolving defatted corn germ powder in sodium bicarbonate solution, wherein the mass ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com