Calcium oxide-loaded porous alkaline carbon material with magnetic property as well as preparation method and application of calcium oxide-loaded porous alkaline carbon material

A technology of magnetic properties and calcium oxide, applied in chemical instruments and methods, catalyst activation/preparation, liquid carbon-containing fuels, etc., can solve the problems of land occupation, unused, and no utilization channels, etc., achieve good magnetic properties, reduce Decomposition temperature, realize the effect of multiple recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

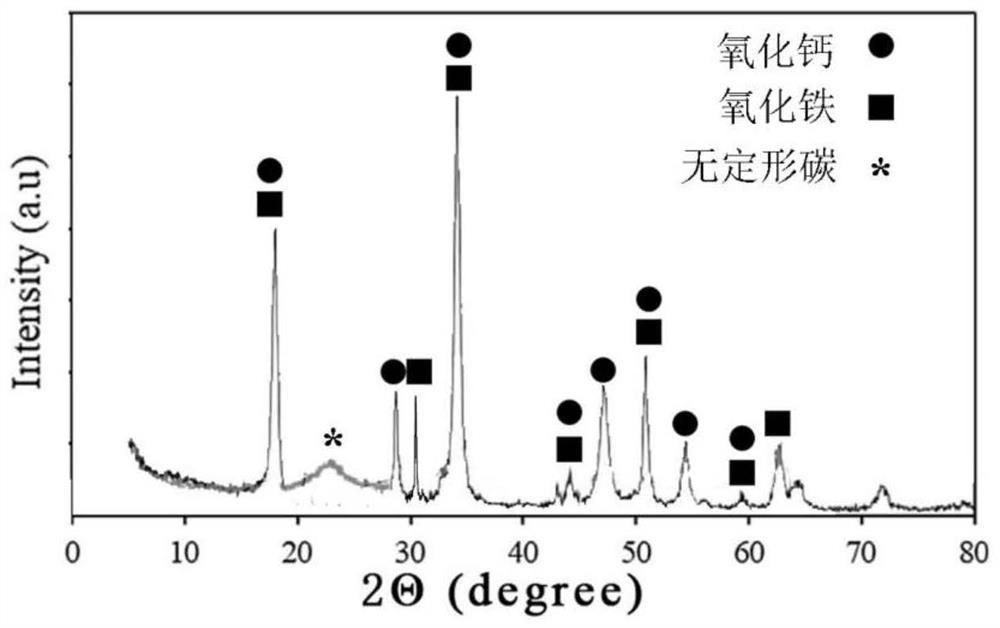

[0044] The preparation of the magnetically porous basic carbon material loaded with calcium oxide involves the following steps:

[0045] (1) Pretreatment of solid waste phosphogypsum

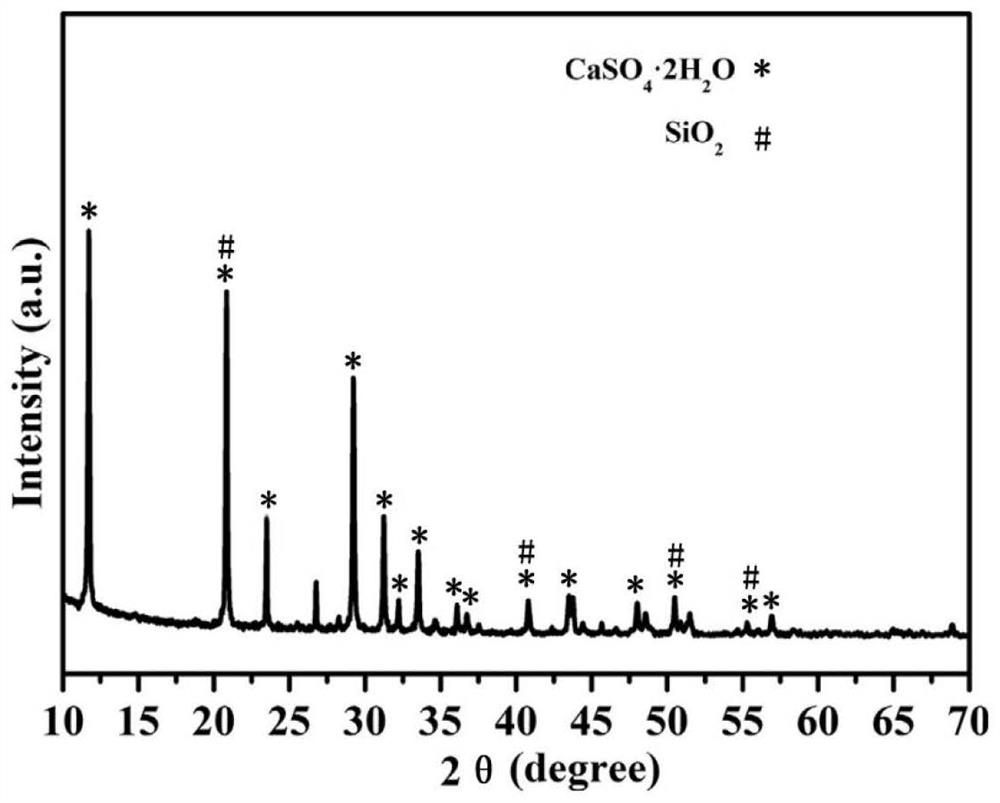

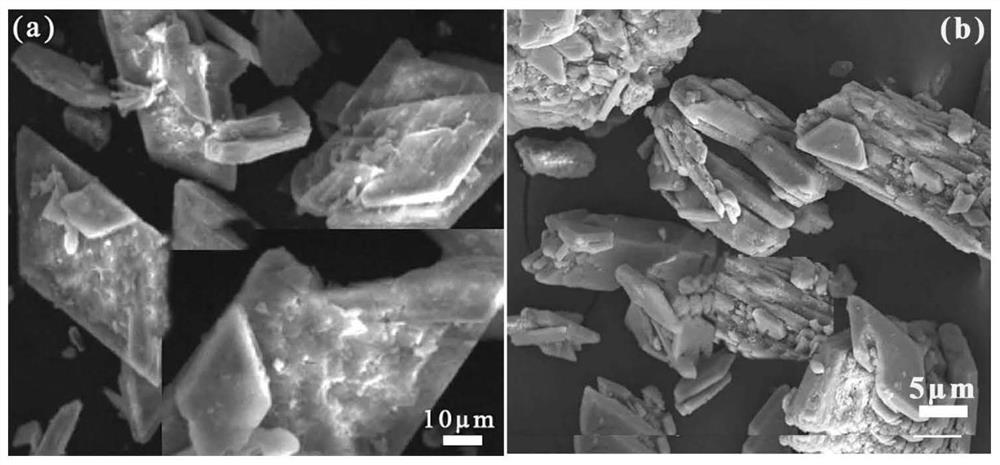

[0046] The solid waste phosphogypsum is dried in an oven at 50°C to constant weight, crushed by a crusher, ground by a ball mill, and sieved by a standard sieve to obtain pretreated solid waste phosphogypsum powder with a particle size of less than 300 mesh. The XRD pattern and SEM photo of solid waste phosphogypsum are as follows figure 1 and figure 2 shown.

[0047] (2) Preparation of porous basic carbon materials

[0048] Mix 1 g of pretreated solid waste phosphogypsum, 2 g of coal tar pitch (purchased from Hebei Fengtaiyuan Energy Technology Co., Ltd.) and 1 g of ferric chloride, dissolve in 50 mL of nitrogen methyl pyrrolidone solution, and stir magnetically for 3 h at 80 ° C . The solvent in the reaction system was evaporated to dryness to obtain a gray-black solid (porous basic carb...

Embodiment 2

[0054] The preparation of the magnetically porous basic carbon material loaded with calcium oxide involves the following steps:

[0055] (1) Pretreatment of solid waste desulfurization gypsum

[0056] The solid waste desulfurized gypsum was dried in an oven at 60°C to constant weight, crushed by a crusher, ground by a ball mill, and sieved by a standard sieve to obtain solid waste desulfurized gypsum powder with a particle size of less than 250 mesh.

[0057] (2) Preparation of porous basic carbon materials

[0058] Mix 1g of pretreated solid waste desulfurization gypsum, 3g of petroleum asphalt (purchased from Hebei Fengtaiyuan Energy Technology Co., Ltd.) and 1.5g of ferrous chloride, dissolve in 50mL of carbon tetrachloride solution, and magnetically Stir for 3h. The solvent in the reaction system was evaporated to dryness to obtain a gray-black solid (porous basic carbon material precursor).

[0059] Put the gray-black solid in a tube furnace (nitrogen atmosphere), cont...

Embodiment 3

[0063] The preparation of the magnetically porous basic carbon material loaded with calcium oxide involves the following steps:

[0064] (1) Pretreatment of solid waste citrate gypsum

[0065] The solid waste citric acid gypsum was dried in an oven at 70°C to constant weight, crushed by a crusher, ground by a ball mill, and sieved by a standard sieve to obtain solid waste citric acid gypsum powder with a particle size below 250 mesh.

[0066] (2) Preparation of porous basic carbon materials

[0067] Mix 2 g of pretreated solid waste citrate gypsum, 8 g of petroleum pitch (purchased from Hebei Fengtaiyuan Energy Technology Co., Ltd.) and 3 g of ferric oxide, dissolve in 50 mL of tetrahydrofuran solution, and stir magnetically for 3 h at 100 ° C. The solvent in the reaction system was evaporated to dryness to obtain a gray-black solid (porous basic carbon material precursor).

[0068] The gray-black solid was placed in a tube furnace (nitrogen atmosphere), and the heating rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com