High-temperature-resistant solid acid catalyst based on direct coal liquefaction heavy organic component and preparation method and application of catalyst

A solid acid catalyst, coal direct liquefaction technology, applied in the direction of preparation of organic compounds, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the problem of poor high temperature resistance and heavy coal liquefaction Solve the problems of difficult utilization of organic fractions, and achieve the effects of good thermal stability, high mechanical strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

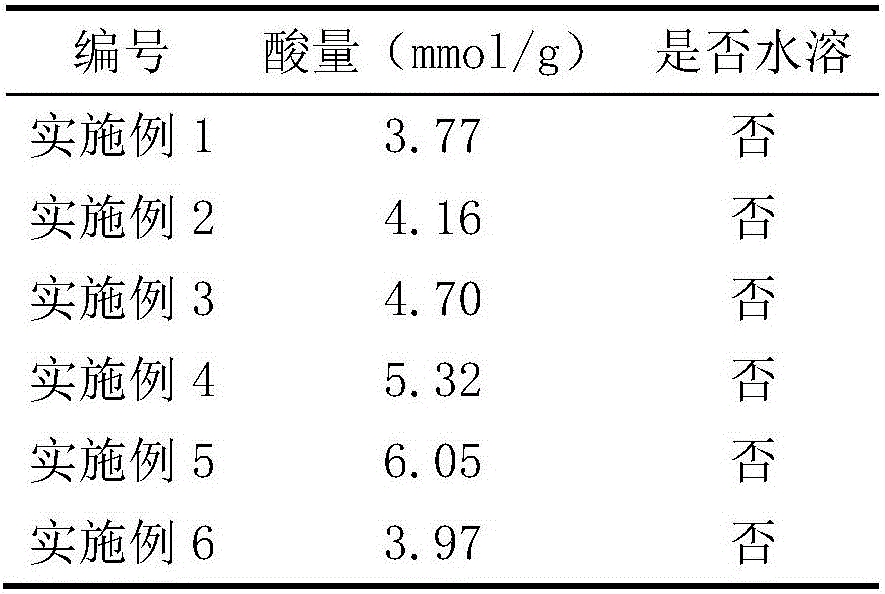

Examples

Embodiment 1

[0025] Mechanically mix 10g of ground coal direct liquefaction heavy organic matter with 3g of p-phenylenedimethanol, and mechanically stir it under an inert atmosphere at 120°C to obtain a molten viscous mixture, then add 0.5g of p-toluenesulfonic acid , After reacting for 3 hours, the temperature was raised to 160°C and kept for 4 hours to obtain product A. A certain amount of product A was weighed and placed in a muffle furnace, and kept at 500° C. for 6 h under a flowing helium atmosphere (100 ml / min) to obtain product B. Weigh 1 g of product B in a reactor, and add 20 g of 50% fuming sulfuric acid. Under the argon gas flow rate of 100ml / min, the temperature was raised to 80°C, and the mixture was continuously stirred. After reacting for 2 hours, stop the reaction, suction filter and wash the obtained product until the filtrate is neutral, until no sulfate ions are detected in the filtrate with barium chloride aqueous solution, and then dry the filter cake to obtain a hig...

Embodiment 2

[0027] Mix 10g of the ground coal direct liquefaction heavy organic matter with 4g of benzaldehyde evenly, and under an inert atmosphere at 140°C, mechanically stir to obtain a molten viscous mixture, then add 0.1g of 98% sulfuric acid solution, and react for 3 hours , and then raise the temperature to 160° C., and keep the temperature for 4 hours to obtain the product A. A certain amount of product A was weighed and placed in a muffle furnace, and the temperature was raised to 600° C. under a flowing argon atmosphere (100 ml / min), and kept for 3 hours to obtain product B. Weigh 1 g of product B into a reactor, and add 20 g of chlorosulfonic acid. Under the nitrogen flow rate of 300ml / min, the temperature was raised to 60°C, and the mixture was stirred continuously. After reacting for 24 hours, stop the reaction, suction filter and wash the obtained product until the filtrate is neutral, until no sulfate ions are detected in the filtrate with barium chloride aqueous solution,...

Embodiment 3

[0028] Mechanically mix 10g of ground coal directly liquefied heavy organic matter with 3g of paraformaldehyde, and mechanically stir under an inert atmosphere at 120°C to obtain a molten viscous mixture, then add 0.5g of 50% sulfuric acid solution, and react After 4 hours, the temperature was raised to 160° C. and kept for 4 hours to obtain product A. A certain amount of product A was weighed and placed in a muffle furnace, and kept at 180° C. for 12 h under a flowing air atmosphere (500 ml / min) to obtain product B. Take by weighing product B1g in reactor, add 30 grams of fuming sulfuric acid (15wt% SO 3 ). Under the nitrogen flow rate of 250ml / min, the ice bath was cooled to 0°C, and the stirring was continued. After reacting for 48 hours, stop the reaction, suction filter and wash the obtained product until the filtrate is neutral, until no sulfate ions are detected in the filtrate with barium chloride aqueous solution, and then dry the filter cake to obtain a high temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com