Method of industrialized production of single bud seed stems of sugarcanes and application of method

A factory-based, sugarcane technology, applied in application, sugarcane cultivation, seed and rhizome treatment, etc., can solve the problems of difficulty in mechanized planting, high cost of seedling shipment, and high cost of seedlings, and achieves good disease and insect control effects and saves money. Transportation cost, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of factory production method for sugarcane single-bud stem, it comprises the following steps:

[0030] (1) Choose Guitang No. 29 sugarcane variety with strong perennial roots, good comprehensive properties, and large market demand (you can also choose Guitang No. 31, Guitang No. 42, Guitang No. 44, Guitang No. 46, and Guitang 49. No., etc.), use healthy nutrition cup seedlings or second-generation seedlings of virus-free seedlings that have been detoxified by shoot tip tissue culture, and choose to plant 1000-1100 plants or about 3000 buds per mu in May to June each year. , and strictly follow the technical requirements of seedling production and cultivation to manage to ensure that sugarcane seeds are free from diseases and insect pests. In the later stage of jointing of seedlings, drones are used to spray sugarcane-specific growth agents, which are composed of 15ppm gibberellic acid, 1.5% potassium dihydrogen phosphate and 0.6% fulvic acid. Spray the leaves ev...

Embodiment 2

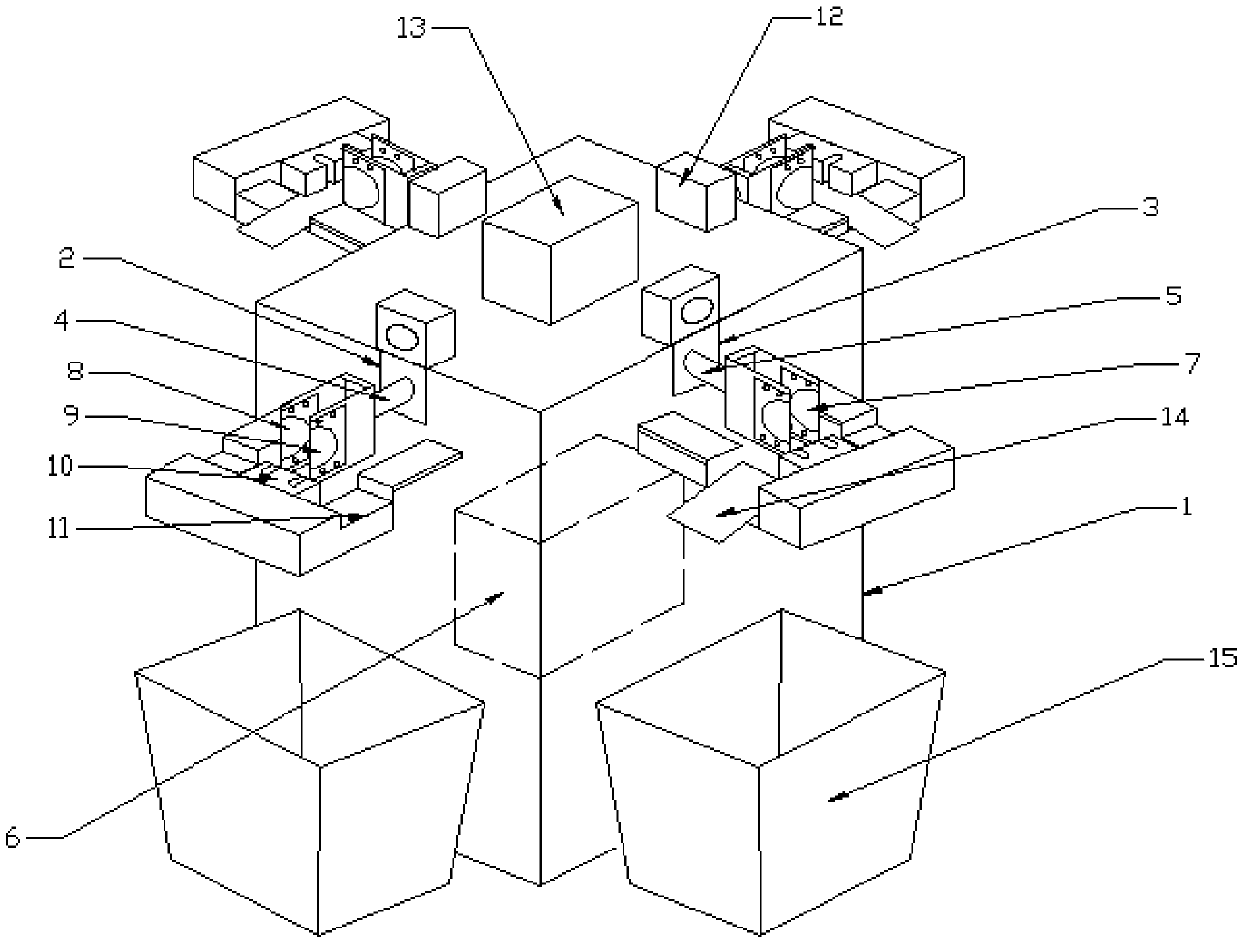

[0037] Such as figure 1 Shown, a kind of sugarcane seed cutting machine comprises frame 1, and described frame 1 top is provided with mutually vertical first guide groove 2 and second guide groove 3; Described first guide groove 2 is provided with first The sliding rod 4, the second guiding groove 3 is provided with a second sliding rod 5, the first sliding rod 4 is driven by the hydraulic device 6 to slide left and right, and the second sliding rod 5 is driven by the hydraulic device 6 to slide forward and backward; Both ends of the first sliding bar 4 and the second sliding bar 5 are provided with a cutting knife 7, and the cutting knife 7 includes a parallel vertical first cutting knife 8 and a second cutting knife 9, the first cutting knife 8 and the second cutting knife 9 The spacing of the second cutting knife 9 is 4cm; The outside of the cutting knife 7 is provided with a cutting block 10 matched with the cutting knife 7, and sugarcane is also arranged on both sides of ...

Embodiment 3

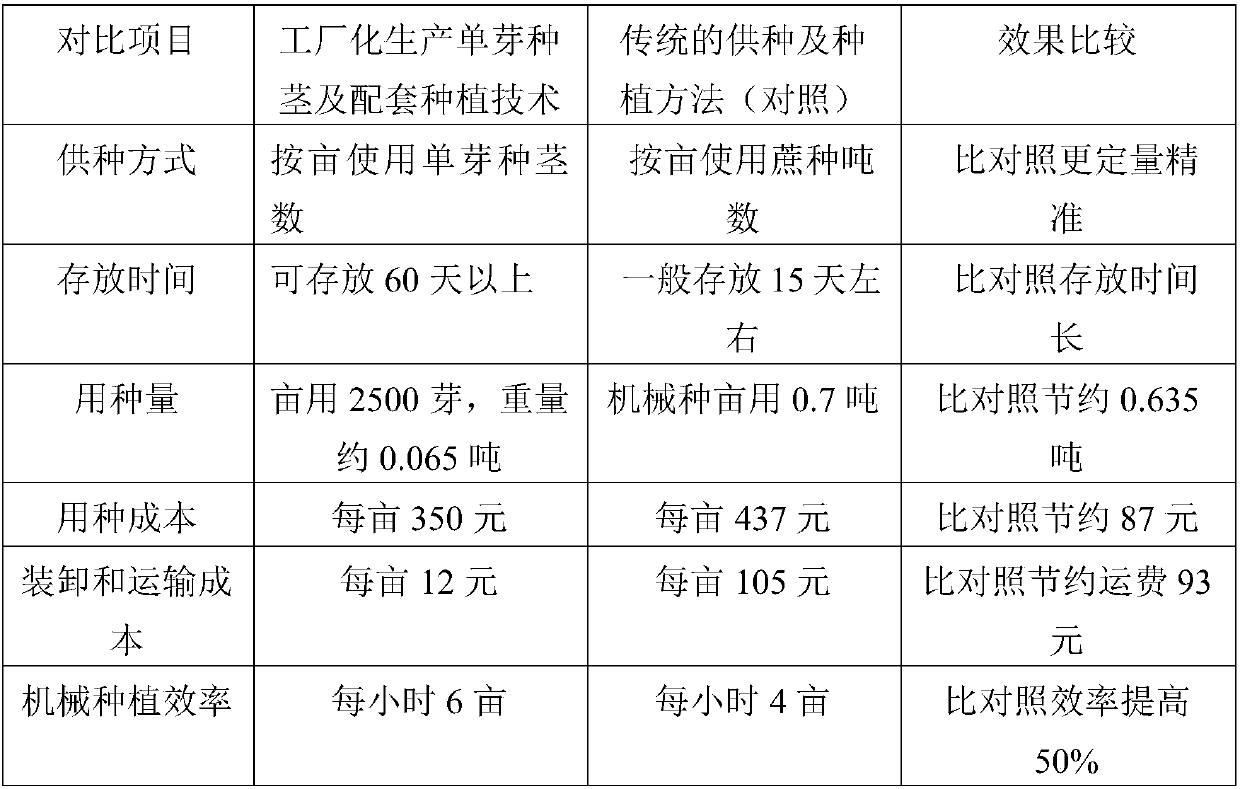

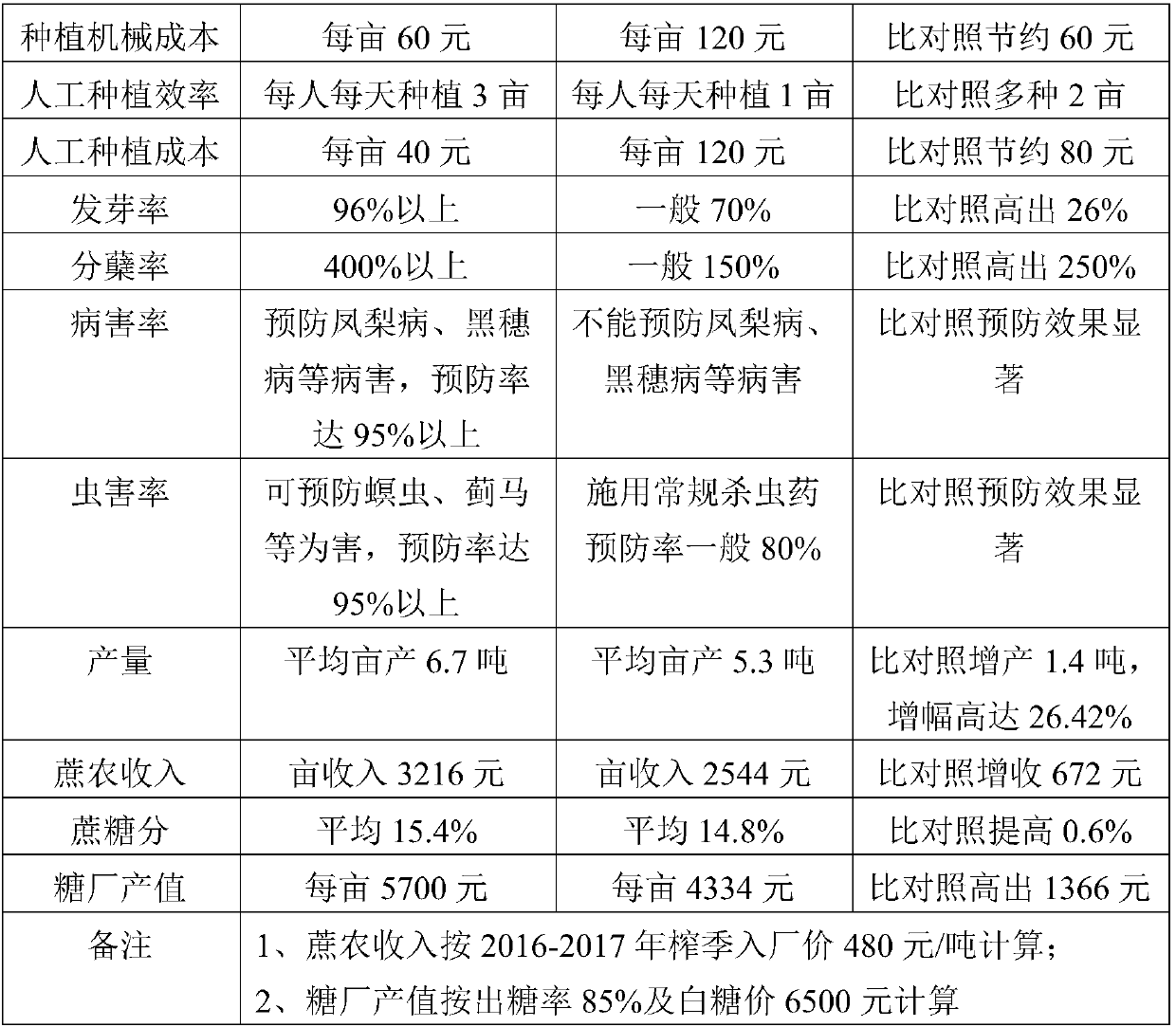

[0042] The 1,500-mu Guangxi sugar cane third-level good propagation base adopts the above-mentioned industrial production of sugarcane single-bud seed stems and its supporting planting technology to provide planting and production in sugarcane areas.

[0043] The supporting cultivation technology included in the QR code is used to plant and cultivate single-bud seed stems. Use machinery to carry out deep plowing, loosening and deep opening, with a row spacing of 1.2 meters and a plant spacing of 0.18-0.23 meters. A single-head transplanter produced by Shandong Qingzhou Huorong Machinery Manufacturing Co., Ltd. was used for quantitative sowing, liquid fertilizer application, soil covering, herbicide sealing and film covering. The planting amount per mu is 2,500 single-bud stems, and other field management is the same as the general high-yield and high-sugar cultivation techniques.

[0044] The above-mentioned 1,500-mu Guangxi sugarcane third-level good propagation base adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com