Method for recovering highly-magnetic materials during preparation of positive electrode precursor materials and preparation method of nickel-cobalt-manganese precursor material

A precursor, nickel-cobalt-manganese technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problems that are wrapped in during the process and cannot be removed when iron is removed from the positive electrode material. Difficulty, battery performance degradation and other problems, to avoid high content of magnetic substances, reduce production costs, and the effect of considerable recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

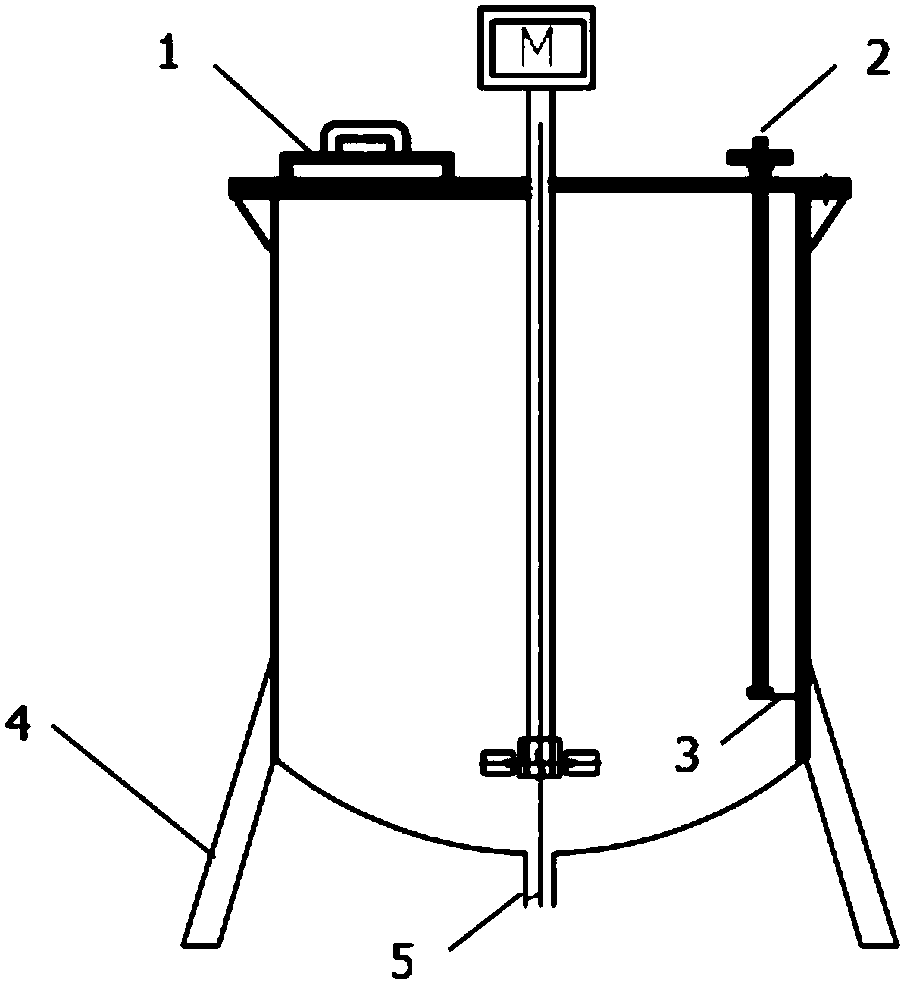

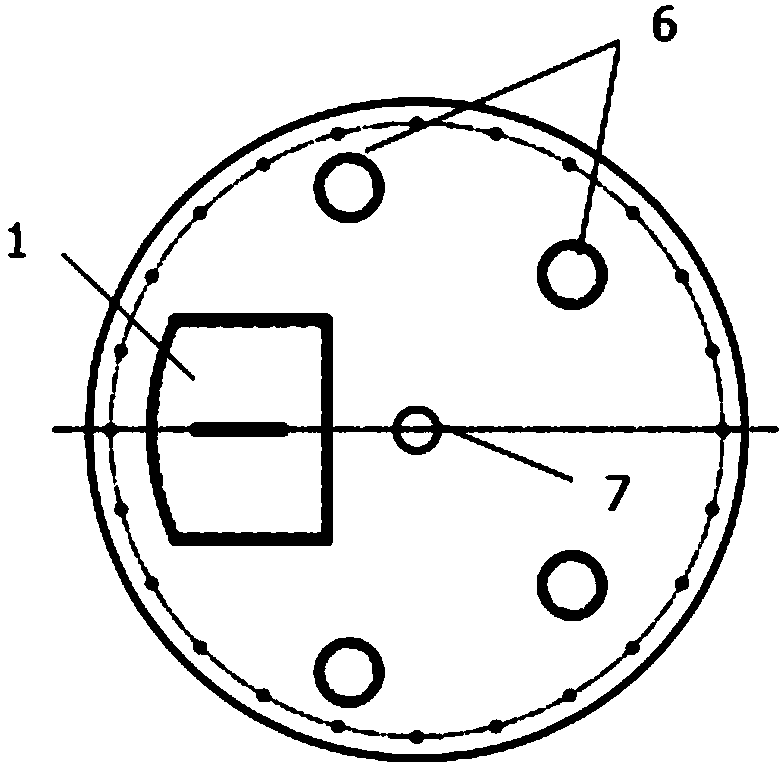

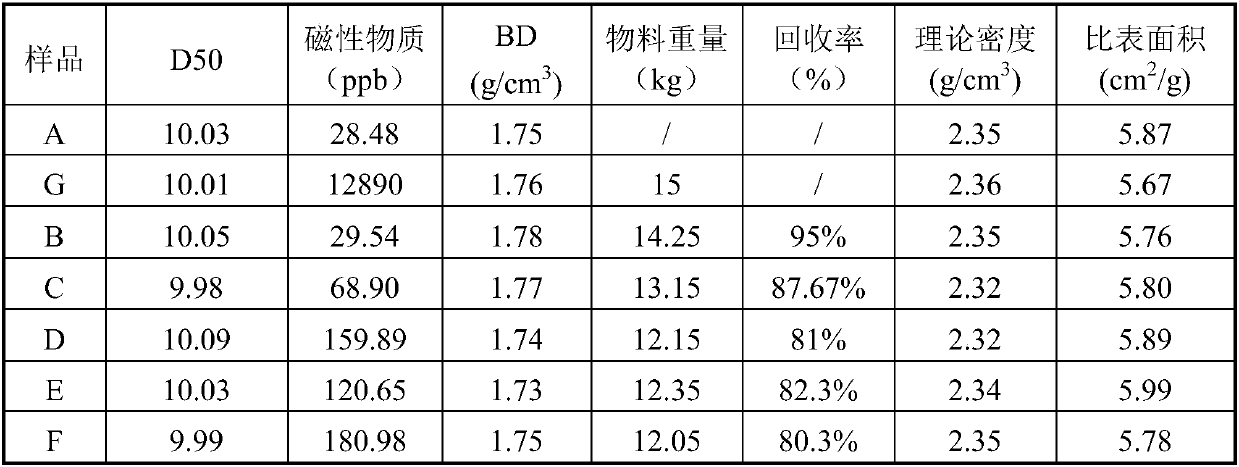

Embodiment 1

[0035] A method for recovering high-magnetic materials in the preparation of positive electrode precursor materials according to the present invention, comprising the following steps: mixing the high-magnetic materials and pure water and stirring evenly to obtain a slurry with a solid content of 240g / L, Add the slurry to the figure 1 In the stirred kettle with permanent magnetic iron remover shown, the slurry is added through the feeding port 1, and then the engine on the stirring shaft 7 is turned on to stir for 50 minutes, and then the magnetic rod 2 is taken out to clean and separate the magnetic substance, and then the demagnetized The finished slurry is released through the vent 5, and after filtering and drying, a positive electrode precursor product is obtained. The magnetic flux of the magnetic bar in the stirred tank with permanent magnet iron remover is 10000 gauss, and the number of magnetic bars is 5. The magnetic bar is inserted into the stirred tank from the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com