Method for separating cobalt and manganese in cobalt and manganese wastes

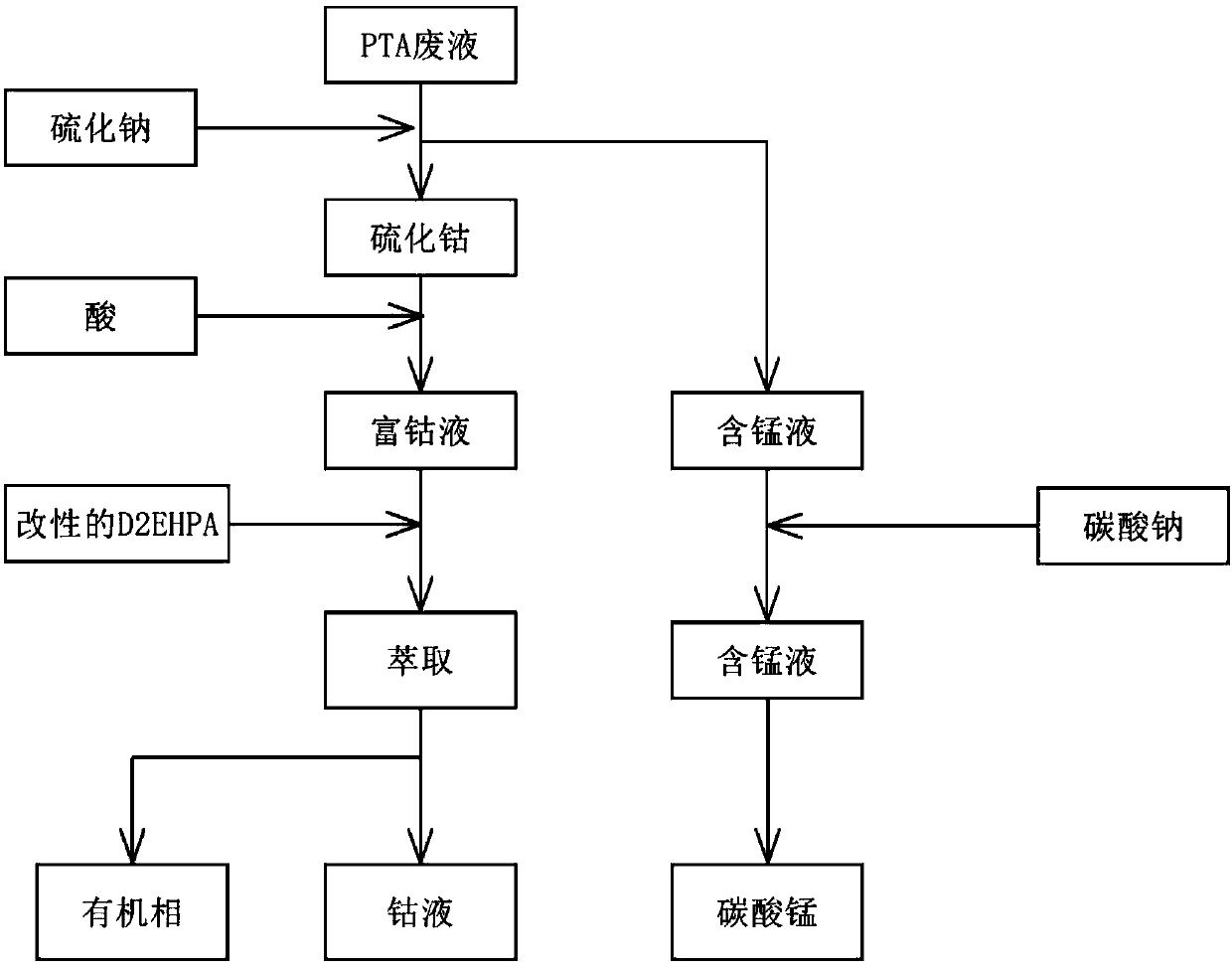

A technology for separating cobalt and separating waste liquid is applied in the direction of improving process efficiency, which can solve the problems of cobalt and manganese entrainment, many extraction stages, and inability to separate cobalt and manganese, and achieves improved purity, simple process, and avoidance of cobalt recovery. rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The cobalt-manganese waste treated in this embodiment is waste cobalt-manganese waste liquid produced in the production of PTA, wherein the content of cobalt is 29.55g / L, and the content of manganese is 67.66g / L. A kind of sulfidation precipitation-modified D2EHPA extraction combined technology of this embodiment separates cobalt and manganese in waste PTA cobalt-manganese catalyst, including the following steps:

[0028] (1), take 30g CoSO 4 ·7H 2 O salt was dissolved in 150ml deionized water and 150ml D2EHPA (V D2EHPA :V 煤油 =4) mixing, adjusting the pH to 4, and filtering to obtain Co-D2EHPA after the reaction;

[0029] (2) Take 50ml of cobalt-manganese waste liquid, adjust the pH value to less than 3.5 with sulfuric acid, heat in a water bath at 90°C for 30 minutes, and filter with suction to remove organic matter and iron ions in the waste liquid. The measured cobalt content in the waste liquid is 29.55g / L, and the manganese content is 67.66g / L. If there are ir...

Embodiment 2

[0035] The cobalt and manganese in the cobalt and manganese of a kind of sulfidation precipitation of this embodiment-modified D2EHPA extraction combined technology separation waste PTA cobalt-manganese catalyst are different from embodiment 1 in that:

[0036] The acid added in step 6) is sulfuric acid, and the pH of the control solution is 2.

[0037] The number of extraction stages in step 6) is 6, O / A: 1:3.

[0038] The recovery rate of cobalt in this experiment was 93%, and the separation ratio of cobalt and manganese reached 8000:1.

Embodiment 3

[0040] The cobalt and manganese in the cobalt and manganese of a kind of sulfidation precipitation of this embodiment-modified D2EHPA extraction combined technology separation waste PTA cobalt-manganese catalyst are different from embodiment 1 in that:

[0041] The sulfide used in step 2) and step 3) is sodium hydrosulfide, and the concentration of sodium hydrosulfide is 0.5mol / L.

[0042] The acid added in step 6) is sulfuric acid, and the pH of the control solution is 3.

[0043] The number of extraction stages in step 6) is 7, O / A: 1:2.

[0044] The recovery rate of cobalt in this experiment was 90%, and the separation ratio of cobalt and manganese reached 8000:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com