MEMS deformable mirror driven by multiple layers of planar electromagnetic coils and making method thereof

A technology of multi-layer coils and electromagnetic coils, applied in optical components, optics, instruments, etc., can solve the problems of increasing production costs and high process requirements, and achieve the effects of reducing thermal resistance, process simplification, process difficulty and simplification of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

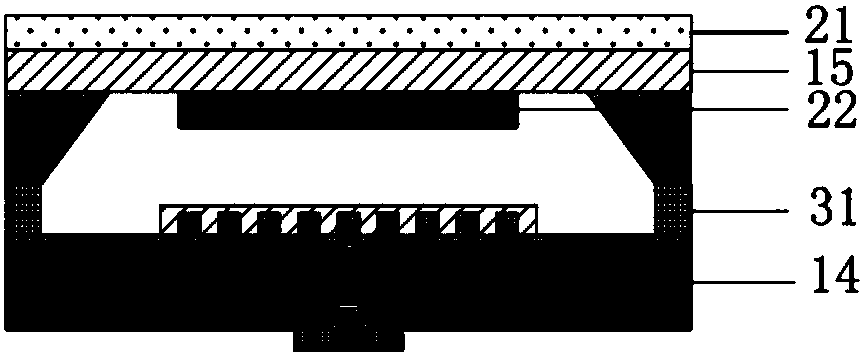

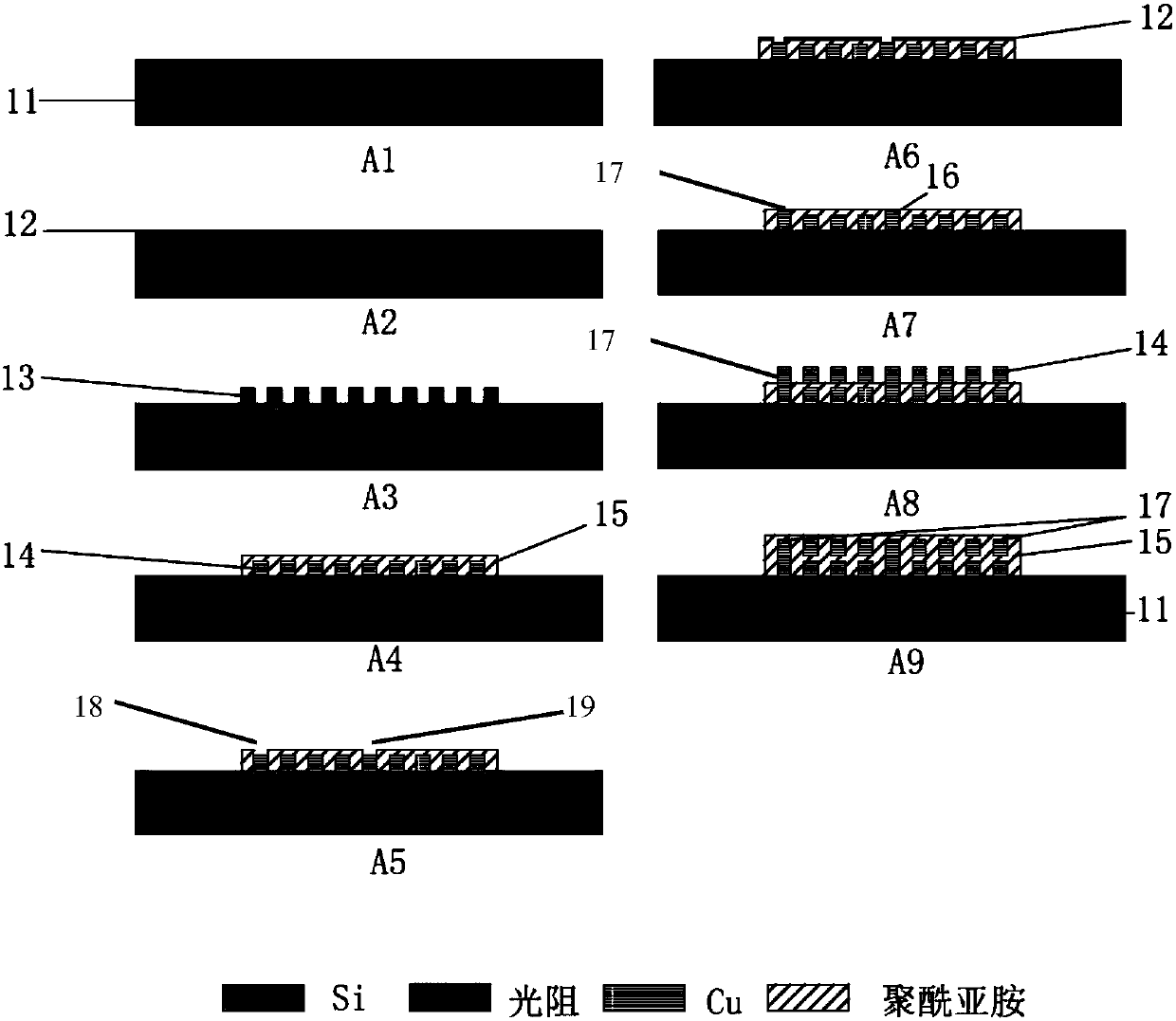

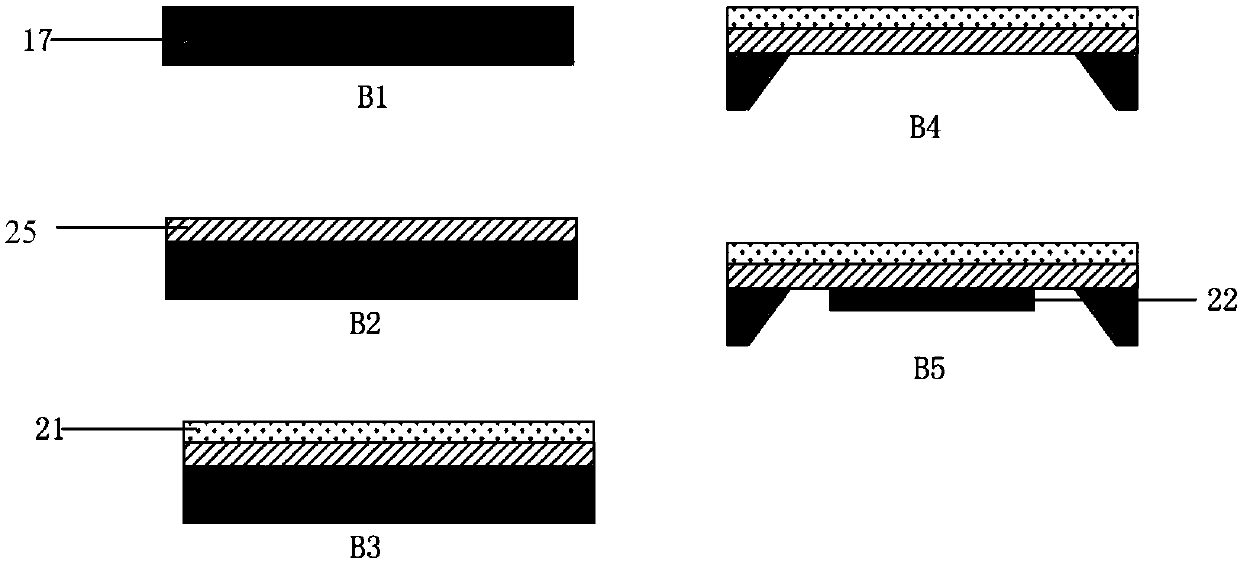

[0049]In the first exemplary embodiment of the present invention, a method for manufacturing a MEMS deformable mirror driven by a double-layer planar electromagnetic coil is provided.

[0050] Please refer to figure 2 , image 3 , Figure 4 with Figure 7 In this embodiment, a method for manufacturing a MEMS deformable mirror driven by a double-layer planar electromagnetic coil includes:

[0051] A Make a multilayer planar coil driver:

[0052] Step A1, preparing a single-sided polished Si wafer 11;

[0053] Step A2, sputtering Cu plating seed layer 12;

[0054] Step A3, using photolithography technology to prepare coil photoresist 13 on the Si surface;

[0055] Step A4, electroplating the Cu coil 14, removing the photoresist, removing the seed layer, and coating polyimide 15;

[0056] Step A5, photolithography, etching polyimide, windowing out the pad point 18 and center point 19 of the coil 14;

[0057] Step A6, sputtering Cu seed layer 12;

[0058] Step A7, perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com