Synthesis of expanded graphite-tin oxide composite material and application of expanded graphite-tin oxide composite material in lithium ion battery

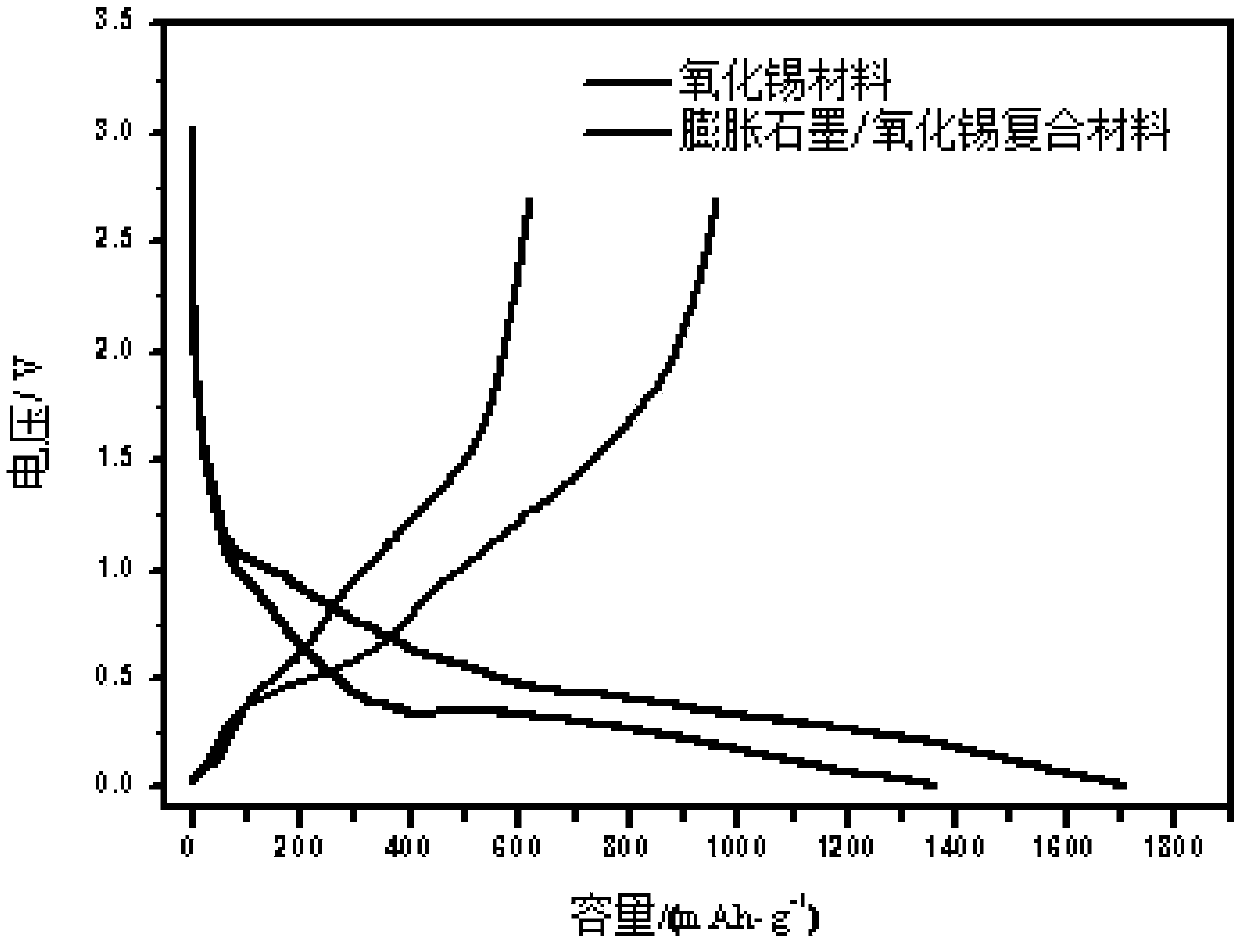

A lithium-ion battery and expanded graphite technology, which is applied in graphene, battery electrodes, secondary batteries, etc., can solve the problems of electrode deactivation, poor cycle performance, and large initial irreversible capacity, so as to improve specific capacity and cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Low temperature oxidation of graphite

[0030] Add 60ml of sulfuric acid with a concentration of 95% and 20ml of nitric acid with a concentration of 60% into the three-necked flask, add 5g of graphite under stirring, keep stirring at 0°C for 30min, then slowly add 10g of potassium permanganate into it, and keep it at 0°C Stir in an ice-water bath for one week. Then take it out, add distilled water, wash several times until the pH value of the filtrate reaches 6.0, and finally place the sample in a vacuum drying oven at 60°C to fully dry to obtain graphite oxide.

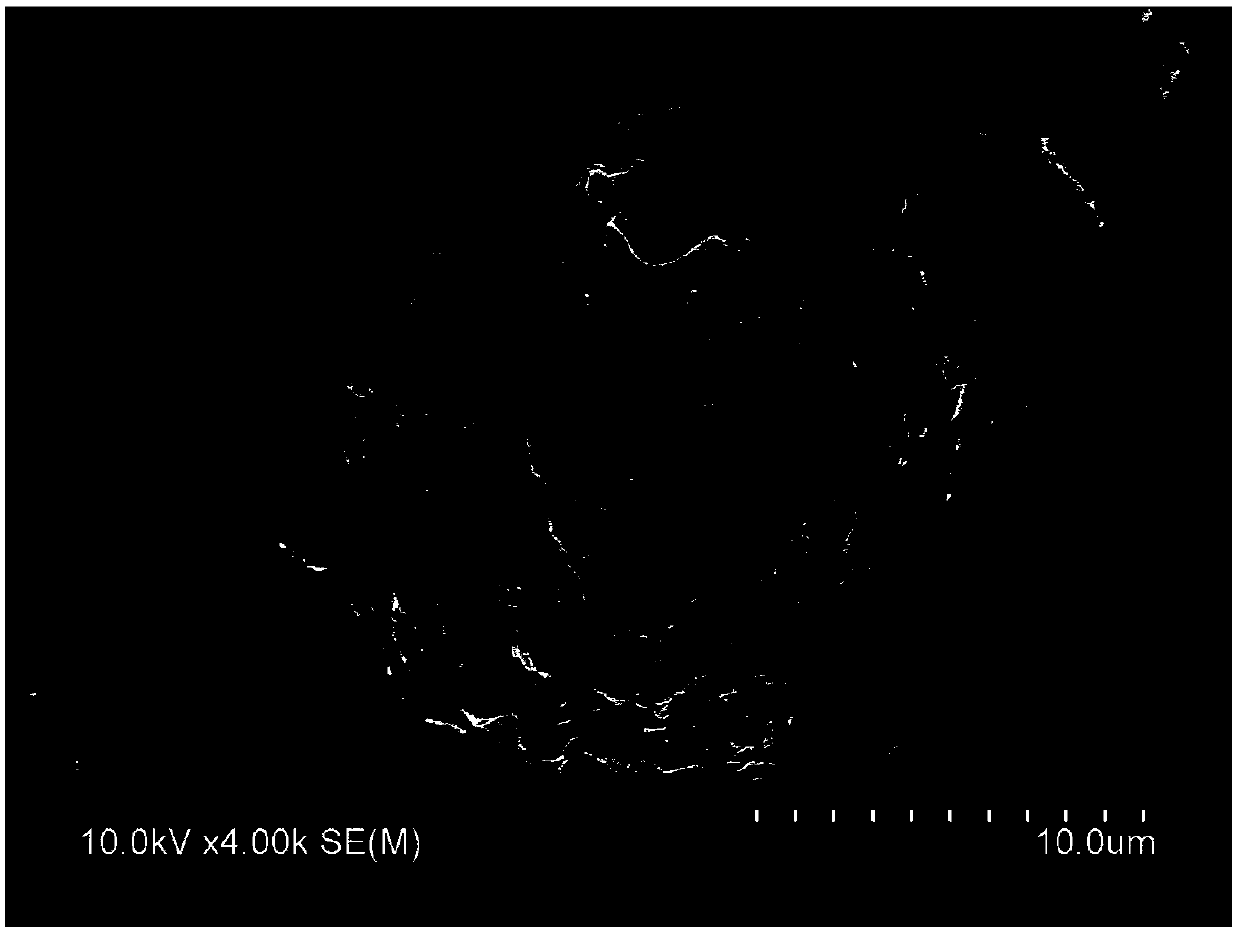

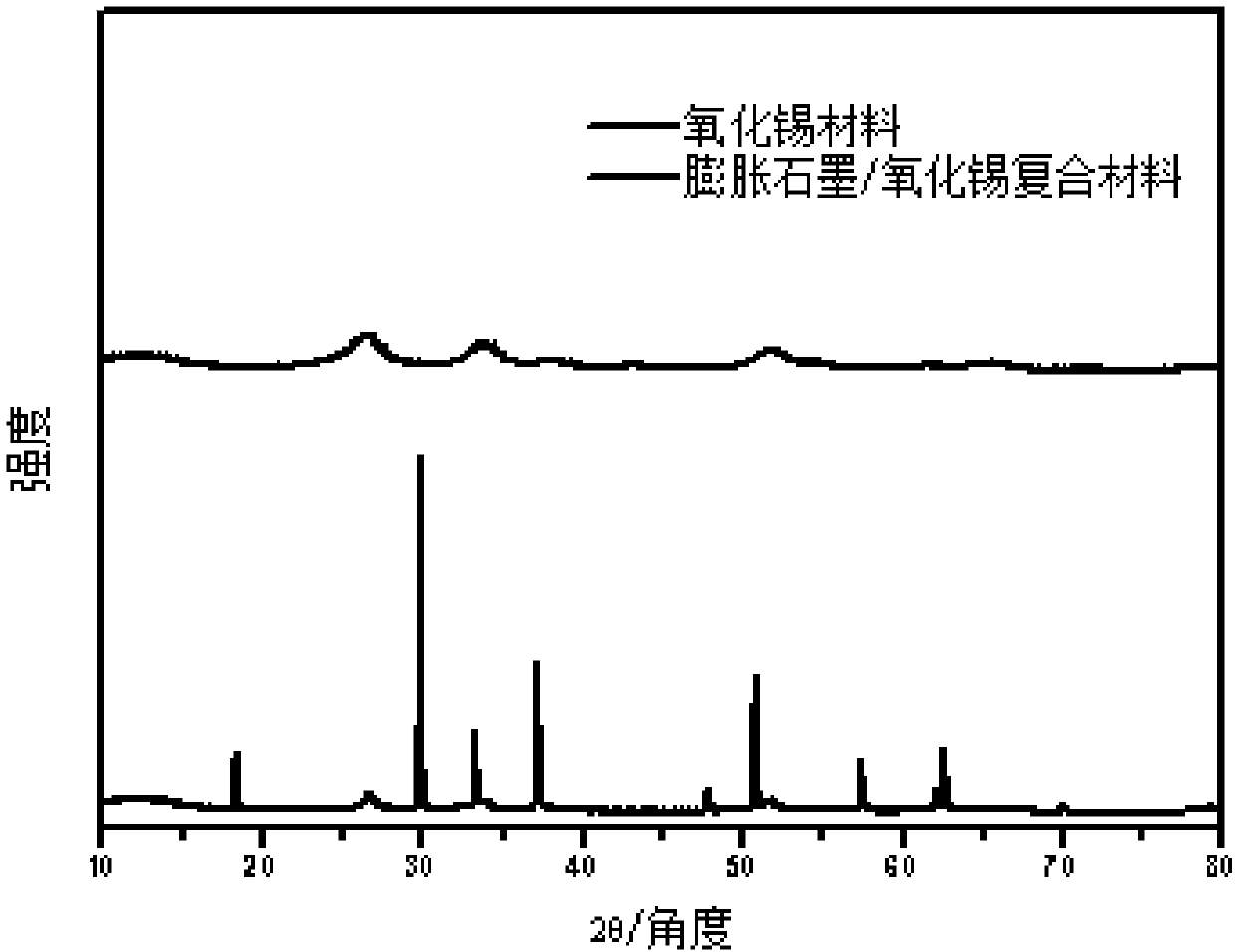

[0031] (2) Preparation of expanded graphite / tin oxide composites

[0032] The graphite oxide prepared in step (1) is mixed with SnCl 4 ·5H 2 Mixed by mass ratio of 1:1, after adding 50mL distilled water, then adding ammonia water (20%) to adjust pH-10, then putting the mixed solution into 100g potassium permanganate and adding it, and keeping it at 0 ° C, the hydrothermal temperature control At 180°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com