An electromagnetic wave shielding/absorbing composite patch and its preparation method

An electromagnetic wave and patch technology, applied in the field of electromagnetic wave shielding/absorbing composite patch and its preparation, can solve the problems such as the inability to fundamentally eliminate electromagnetic waves, the limitation of the use of shielding patch materials, and the short circuit of the shielding patch, so as to improve the shielding performance , Excellent thermal conductivity, the effect of avoiding short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

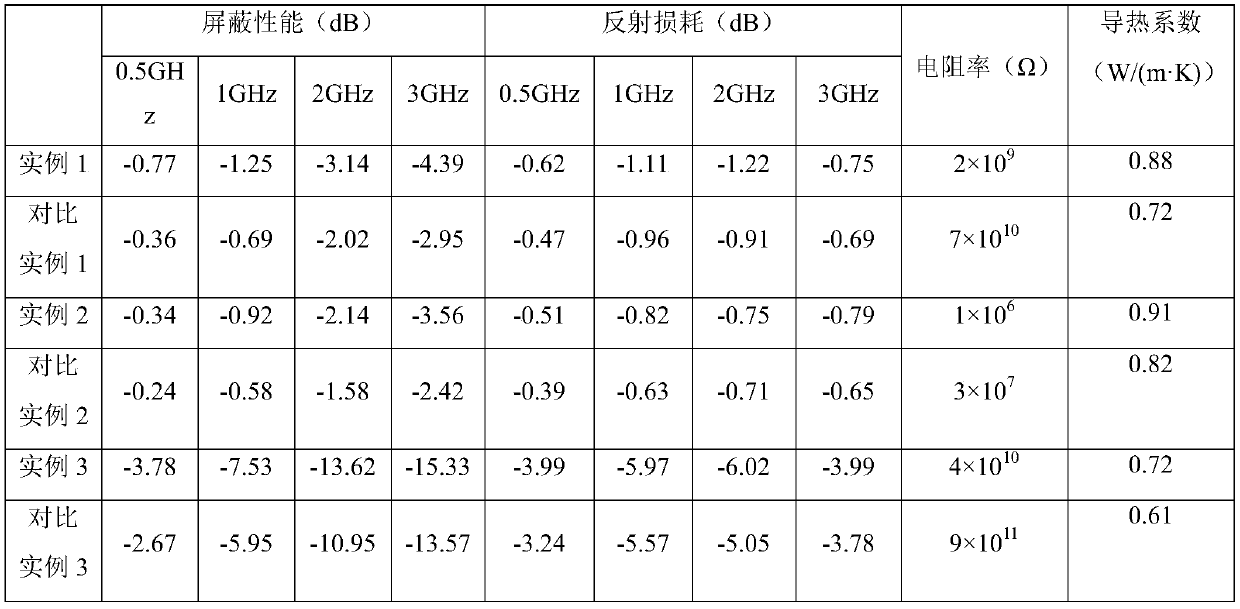

Examples

Embodiment 1

[0033] A method for preparing an electromagnetic wave shielding / absorbing composite patch, comprising the following steps:

[0034] 1) Preparation of wave-absorbing layer: by weight percentage, 10% of polymer binder, 89% of scaly magnetic powder, and 1% of auxiliary materials are mixed evenly to obtain a mixture;

[0035] 2) the mixture in step 1) is made into a sheet-shaped material through a calendering process;

[0036] 3) vulcanize the flake-shaped material prepared in step 2), and the obtained patch is the wave-absorbing layer;

[0037] 4) Preparation of the shielding layer: by weight percentage, 65% of the binder system, 33% of the conductive absorbent, and 2% of the auxiliary agent are mixed, and then a uniform shielding coating is obtained;

[0038] 5) Composite of the wave-absorbing layer and the shielding layer: the shielding coating is coated on the surface of the wave-absorbing layer by a spraying process, and finally the coating is dried and cured to obtain a com...

Embodiment 2

[0055] 1) Preparation of wave-absorbing layer: by weight percentage, polymer binder 9.2%, scaly magnetic powder 90%, and auxiliary materials 0.8%, were mixed evenly to obtain a mixture;

[0056] 2) The mixture in step 1) is made into a sheet-shaped material through a casting process;

[0057] 3) vulcanize the flake-shaped material prepared in step 2), and the obtained patch is the wave-absorbing layer;

[0058] 4) Preparation of the shielding layer: by weight percentage, 55% of the binder system, 42% of the conductive absorbent, and 3% of the auxiliary agent are mixed, and then a uniform shielding coating is obtained;

[0059] 5) Composite of the wave-absorbing layer and the shielding layer: the shielding coating is coated on the surface of the wave-absorbing layer by a spraying process, and finally the coating is dried and cured to obtain a composite patch;

[0060] 6) Preparation of protective layer: The surface of the shielding layer in the composite patch prepared in step...

Embodiment 3

[0076] 1) Preparation of wave-absorbing layer: by weight percentage, 19.5% of polymer binder, 80% of scaly magnetic powder, and 0.5% of auxiliary materials are mixed uniformly to obtain a mixture;

[0077] 2) the mixture in step 1) is made into a sheet-shaped material through a calendering process;

[0078] 3) vulcanize the flake-shaped material prepared in step 2), and the obtained patch is the wave-absorbing layer;

[0079] 4) Preparation of the shielding layer: by weight percentage, 75% of the binder system, 20% of the conductive absorbent, and 5% of the auxiliary agent are mixed, and then a uniform shielding coating is obtained;

[0080] 5) Composite of the wave-absorbing layer and the shielding layer: the shielding coating is coated on the surface of the wave-absorbing layer by a spraying process, and finally the coating is dried and cured to obtain a composite patch;

[0081] 6) Preparation of protective layer: The surface of the shielding layer in the composite patch p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com