Method for preparing para-xylene catalyst by amino-modified methanol

A technology of xylene catalyst and amino modification, which is applied in the direction of catalyst activation/preparation, catalyst, carbon compound catalyst, etc. It can solve the problems of uneven bed temperature, poor catalyst stability, easy deactivation, etc., and achieve improved surface properties and Effects of stability, increase in adsorption capacity, and increase in one-way yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

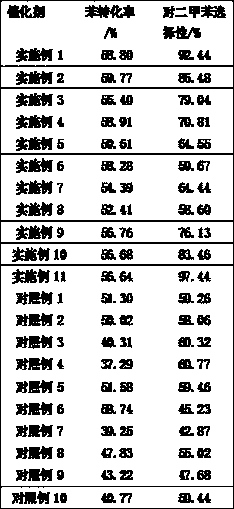

Examples

Embodiment 1

[0017] A preparation method of an amino-modified methanol-based p-xylene catalyst, comprising the following steps:

[0018] Step 1. Freeze-dry 100g of COF-1 nanomaterials and pulverize them, place them in a tube furnace, blow nitrogen gas for 10min, flow rate is 0.5L / min, and rapidly raise the temperature to 350°C and keep the constant temperature for 5h to obtain a thermally expandable porous material;

[0019] Step 2, put the above COF-1 nanomaterials in 1mol / L dilute hydrochloric acid, stir at constant temperature, and filter to obtain a solid; take 100g of the solid, add a mixed solution of 50ml concentrated sulfuric acid and 50ml concentrated nitric acid in a volume ratio, and then mechanically stir for 4 hours , suction filtration,

[0020] wash and dry;

[0021] Step 3. Add the above-mentioned dried product into 25ml of ammonia water, mechanically stir for 15 minutes, add 25g of sodium dithionite, stir at a constant speed for 24 hours, filter with suction, wash and dry...

Embodiment 2

[0029] Step 4, take 20g amino-modified COF-1 nanomaterials, add 160ml containing 15gFeSO 4 ·7H 2 O and 5g PEG-4000 alcohol-water mixed system, in which the volume ratio of water and absolute ethanol is 1:2, pass high-purity nitrogen gas, stir at a constant speed, and add 30ml of KBH with a concentration of 0.5mol / L dropwise at the same time 4 solution, then continuously stirred for 20 min, and vacuum freeze-dried to obtain nano-iron-loaded amino-modified COF-1 catalyst. All the other steps are the same as in Example 1.

Embodiment 3

[0031] Step 4, take 10g amino-modified COF-1 nanomaterials, add 160ml containing 15gFeSO 4 ·7H 2 O and 5g PEG-4000 alcohol-water mixed system, in which the volume ratio of water and absolute ethanol is 1:2, pass high-purity nitrogen gas, stir at a constant speed, and add 30ml of KBH with a concentration of 0.5mol / L dropwise at the same time 4 solution, then continuously stirred for 20 min, and vacuum freeze-dried to obtain nano-iron-loaded amino-modified COF-1 catalyst. All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com