Composite catalyst for performing catalytic combustion on acetic ether, preparation method thereof and application

A technology of ethyl acetate and catalytic combustion, which is applied in the direction of combustion method, physical/chemical process catalyst, combustion type, etc., can solve the problem of low activity at low temperature, and achieve the effects of low cost, high thermal stability, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

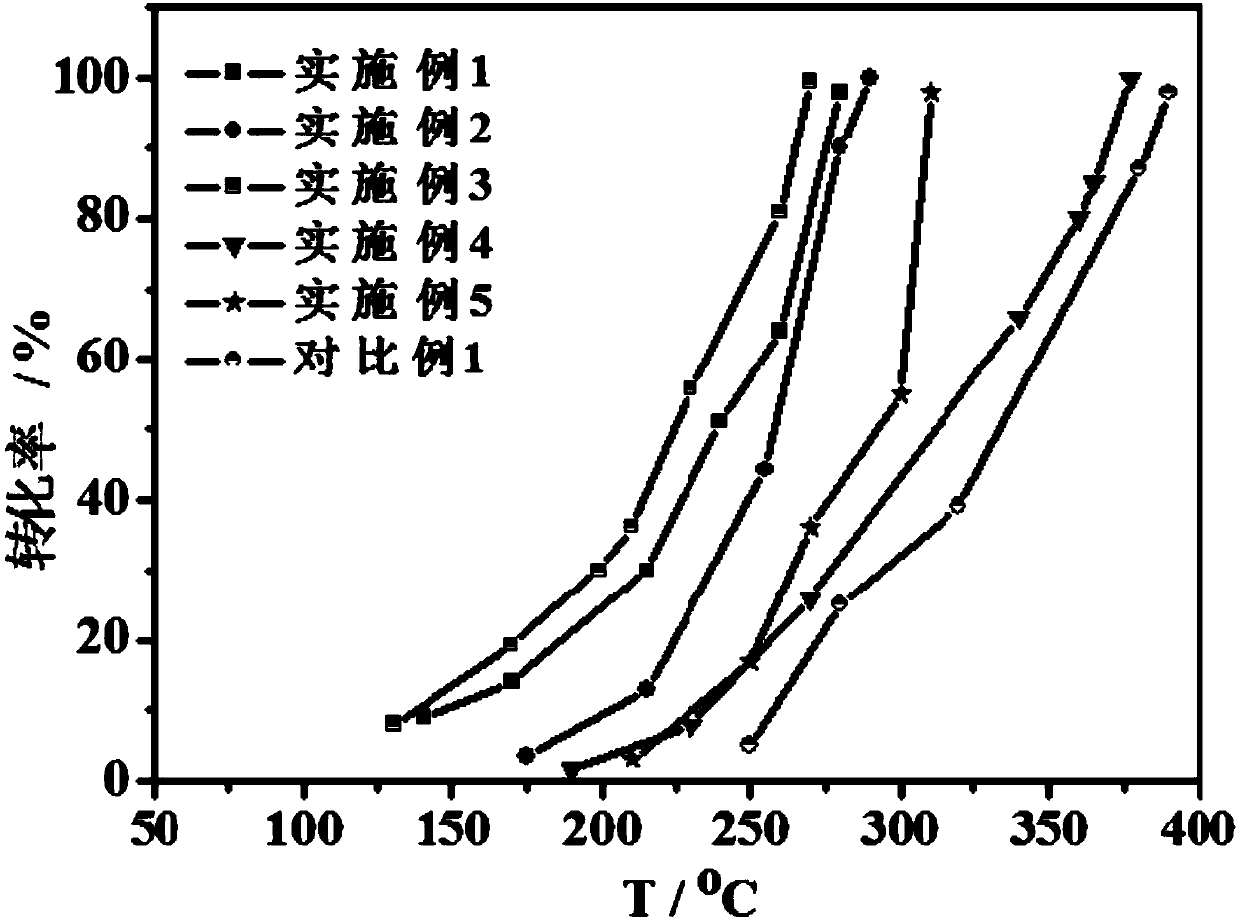

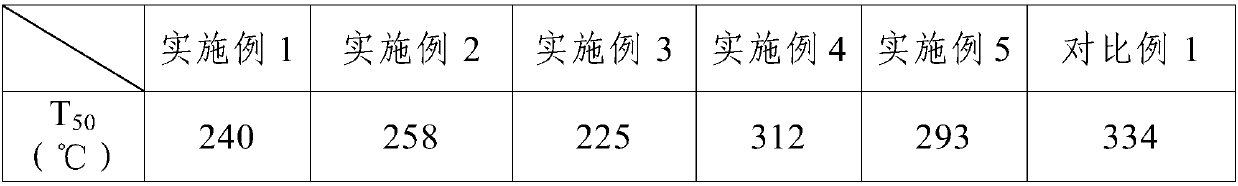

[0025] This embodiment is used for catalytic combustion to ethyl acetate with composite catalyst with Al 2 o 3 As the carrier, the noble metal Pd is used as the active component, and the mass of the metal Pd is the Al 2 o 3 0.2% by mass to load in Al 2 o 3 The composite non-noble metal oxide on the surface is used as an auxiliary agent, and the composite non-noble metal oxide is composed of CeO 2 and SnO 2 Composite, the structural formula is CeO 2 -SnO 2 , the CeO 2 The mass of the Al 2 o 3 5% by mass of the SnO 2 The mass of the Al 2 o 3 4% of mass;

[0026] The preparation method of described composite catalyst comprises the following steps:

[0027] Step 1. Take a 500mL clean beaker, add 300mL deionized water, and then weigh 0.63g Ce(NO 3 ) 3 ·6H 2 O and 0.46g SnCl 4 , after stirring evenly, add 10mL of nitric acid with a mass concentration of 68%, then place it in an ultrasonic oscillator for ultrasonic vibration for 0.5h, and then add 5g of Al to the be...

Embodiment 2

[0033] This embodiment is used for catalytic combustion to ethyl acetate with composite catalyst with Al 2 o 3 As the carrier, the noble metal Pd is used as the active component, and the mass of the metal Pd is the Al 2 o 3 0.2% by mass to load in Al 2 o3 The composite non-noble metal oxide on the surface is used as an auxiliary agent, and the composite non-noble metal oxide is composed of CeO 2 and SnO 2 Composite, the structural formula is CeO 2 -SnO 2 , the CeO 2 The mass of the Al 2 o 3 5% by mass of the SnO 2 The mass of the Al 2 o 3 8% of mass;

[0034] The preparation method of described composite catalyst comprises the following steps:

[0035] Step 1. Take a 500mL clean beaker, add 300mL deionized water, and then weigh 0.63g Ce(NO 3 ) 3 ·6H 2 O and 0.92 g SnCl 4 , after stirring evenly, add 10mL of nitric acid with a mass concentration of 68%, then place it in an ultrasonic oscillator for ultrasonic vibration for 0.5h, and then add 5g of Al to the bea...

Embodiment 3

[0041] This embodiment is used for catalytic combustion to ethyl acetate with composite catalyst with Al 2 o 3 As the carrier, the noble metal Pd is used as the active component, and the mass of the metal Pd is the Al 2 o 3 0.5% by mass to load in Al 2 o 3 The composite non-noble metal oxide on the surface is used as an auxiliary agent, and the composite non-noble metal oxide is composed of CeO 2 and SnO 2 Composite, the structural formula is CeO 2 -SnO 2 , the CeO 2 The mass of the Al 2 o 3 5% by mass of the SnO 2 The mass of the Al 2 o 3 12% of mass;

[0042] The preparation method of described composite catalyst comprises the following steps:

[0043] Step 1. Take a 500mL clean beaker, add 300mL deionized water, and then weigh 0.63g Ce(NO 3 ) 3 ·6H 2 O and 1.38 g SnCl 4 , after stirring evenly, add 10mL of nitric acid with a mass concentration of 68%, then place it in an ultrasonic oscillator for ultrasonic vibration for 0.5h, and then add 5g of Al to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com