Styrene-butadiene latex and its preparation method

A technology of styrene-butadiene latex and emulsifier, which is applied in the field of styrene-butadiene latex and its preparation, and can solve problems such as hot stickiness, cold brittleness, water resistance and unsatisfactory stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Embodiment 1: styrene-butadiene latex, the components included and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0096] S1, under vacuum conditions, the first solvent, divinylbenzene, anionic emulsifier, first emulsifier, hydroxyethyl cellulose, polysorbate-80, acrylic acid, N-hydroxyl Methacrylamide, acrylamide, pH regulator, and polyvinyl alcohol are mixed evenly to form an aqueous phase material;

[0097] S2, under vacuum conditions, the corresponding weight fractions of styrene, butadiene, organic solvent, and ethyl 3-mercaptobutyrate in the oil phase material are uniformly mixed to form the oil phase material;

[0098] S3, mixing the mbs seed latex, sodium dodecylbenzene sulfonate, and the second solvent of the corresponding weight fraction in the primer to form a primer;

[0099] S4, under vacuum conditions, get the third solvent in other materials, 260 parts of water phase materials obtained in step S1,...

Embodiment 2-6

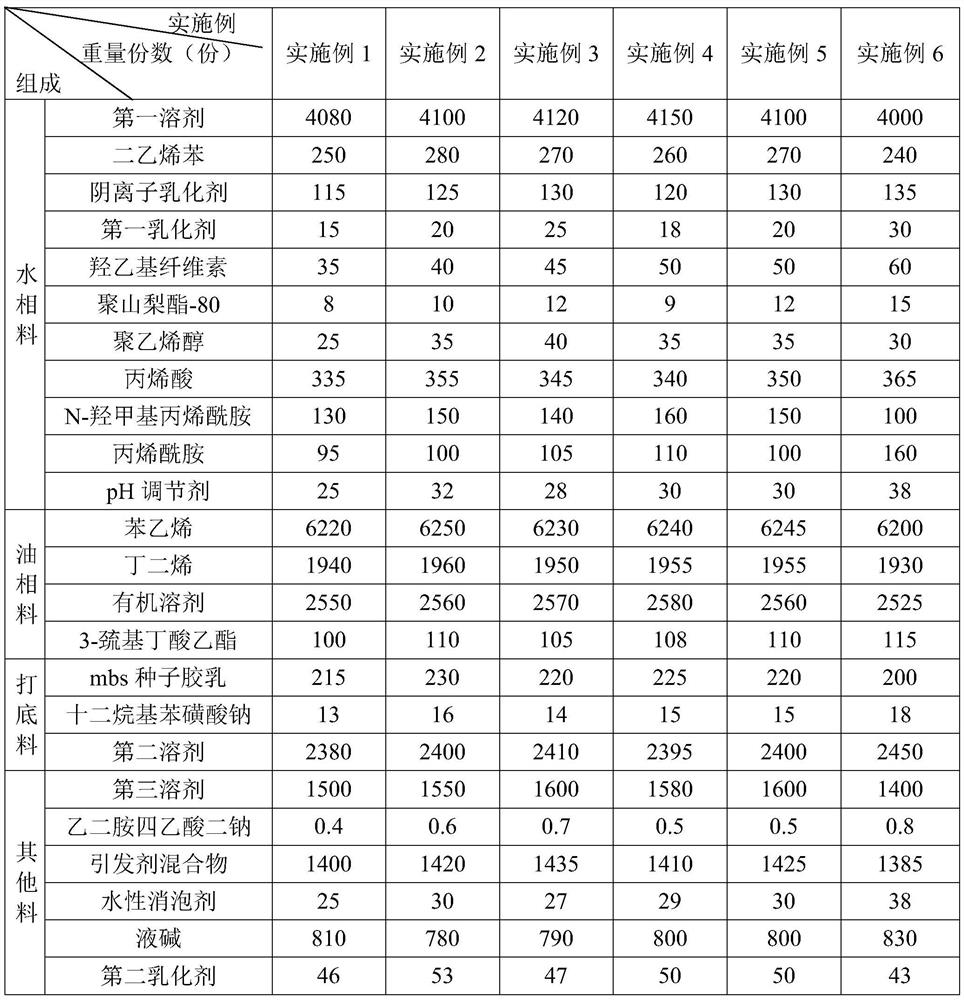

[0104] Examples 2-6: styrene-butadiene latex. The difference from Example 1 is that the components included therein and their corresponding parts by weight are shown in Table 1.

[0105] Table 1 Embodiment 1-6 components and their corresponding parts by weight

[0106]

Embodiment 7

[0107] Embodiment 7: styrene-butadiene latex, the difference from embodiment 1 is that polyvinyl alcohol is not included in the components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com