Treatment method for improving surface crosslinking of water-absorbent resin via vacuum negative-pressure

A water-absorbent resin and vacuum negative pressure technology, which is applied in the treatment field of improving the surface cross-linking of water-absorbent resin by vacuum negative pressure, can solve the problems of water-absorbent resin decline, inability to absorb organic solvents, hidden dangers of preparation process safety, etc. The effect of lowering the temperature and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

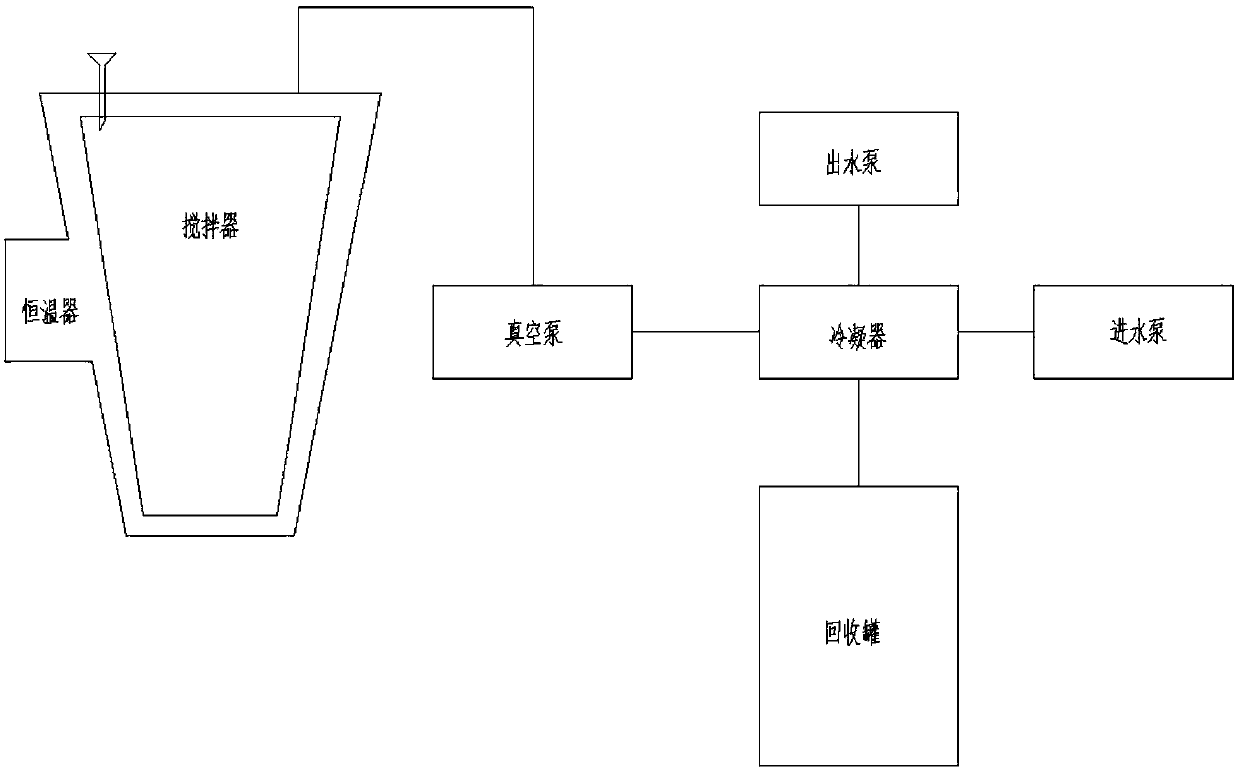

[0030] (1) 100 parts by mass of water-absorbent resin particles to be treated and 6 parts by mass of surface treatment liquid are placed in a stirrer;

[0031] The water-absorbing resin particles to be treated are 20-120 mesh sodium acrylate-acrylic acid copolymer particles, wherein the proportion of 20-80 mesh is 90%.

[0032] The surface treatment liquid is deionized water, methanol, aluminum sulfate, fatty alcohol polyoxyethylene ether, 1,2-propylene glycol, polyethylene glycol diglycidyl ether mixed according to the mass ratio of 6:3:1:0.4:0.5:0.1 solution.

[0033] (2) Set the stirrer speed to 20r / min, set the thermostat temperature to 150°C; set the vacuum degree of the vacuum pump to 0.04Mpa;

[0034] (3) Simultaneously turn on the switches of the thermostat, vacuum pump, agitator, condenser, water outlet pump and water inlet pump, and run the above equipment for 60 minutes;

[0035] (4) Use a recovery tank to collect the organic solvent components condensed by the co...

Embodiment 2

[0037] (1) 100 parts by mass of water-absorbing resin particles to be treated and 8 parts by mass of surface treatment liquid are placed in a stirrer;

[0038] The water-absorbing resin particles to be treated are 20-120 mesh sodium acrylate-acrylic acid copolymer particles, wherein the proportion of 20-80 mesh is 95%.

[0039] The surface treatment liquid is deionized water, methanol, aluminum sulfate, fatty alcohol polyoxyethylene ether, 1,2-propylene glycol, polyethylene glycol diglycidyl ether mixed according to the mass ratio of 6:3:1:0.4:0.5:0.1 solution.

[0040] (2) Set the stirrer speed to 30r / min, set the thermostat temperature to 160°C; set the vacuum degree of the vacuum pump to 0.05Mpa;

[0041] (3) Simultaneously turn on the switches of the thermostat, vacuum pump, agitator, condenser, water outlet pump and water inlet pump, and run the above equipment for 50 minutes;

[0042] (4) Use a recovery tank to collect the organic solvent components condensed by the co...

Embodiment 3

[0044] (1) 100 parts by mass of water-absorbing resin particles to be treated and 10 parts by mass of surface treatment liquid are placed in a stirrer;

[0045]The water-absorbing resin particles to be treated are 20-120 mesh sodium acrylate-acrylic acid copolymer particles, wherein the proportion of 20-80 mesh is 91%.

[0046] The surface treatment liquid is deionized water, ethanol, aluminum sulfate, fatty alcohol polyoxyethylene ether, 1,2-propylene glycol, polyethylene glycol diglycidyl ether mixed according to the mass ratio of 6:3:1:0.4:0.5:0.1 solution.

[0047] (2) Set the stirrer speed to 40r / min, set the thermostat temperature to 160°C; set the vacuum degree of the vacuum pump to 0.06Mpa;

[0048] (3) Simultaneously turn on the switches of the thermostat, vacuum pump, agitator, condenser, water outlet pump and water inlet pump, and run the above equipment for 60 minutes;

[0049] (4) Use a recovery tank to collect the organic solvent components condensed by the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com