A kind of montan wax resin multifunctional liquid mulching film and preparation method thereof

A technology of montan wax resin and liquid mulch, which is applied in the agricultural field, can solve the problems of high acidity of the solution, the use of modified liquid, and the limitation of application technology, etc., and achieve the effect of increasing film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

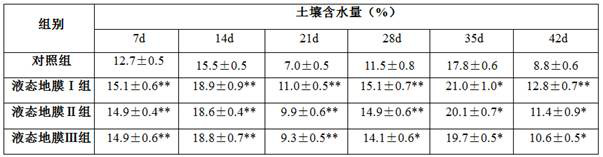

Image

Examples

Embodiment 1

[0020] The composition and parts by weight of the multifunctional liquid mulch film of Mengtan wax resin in this embodiment are: 100 kg of Mengtan wax resin, 100 kg of resin co-solvent, 22 kg of potassium permanganate, 10 kg of polyvinyl alcohol, and 2 kg of triethanolamine , Trimethylolpropane 2kg.

[0021] The preparation method of the resin co-solvent is as follows: according to the mass ratio of polysorbate: propylene glycol: polyethylene glycol = 1:2:3, the three are pre-mixed to obtain a mixture, and then it is formulated into a mass fraction of 30 % aqueous solution.

[0022] The production method of the liquid mulch film is as follows:

[0023] (1) Put the montan wax resin in the reaction kettle, add the resin co-solvent, and carry out mechanical stirring at 80°C, the stirring speed is 60r / min, and the stirring time is 20min.

[0024] (2) After step (1) is completed, add potassium permanganate into the reaction kettle, keep the temperature constant, change the stirri...

Embodiment 2

[0027] The composition and parts by weight of the multifunctional liquid mulch film of Mengtan wax resin in this embodiment are: 150 kg of Mengtan wax resin, 190 kg of resin co-solvent, 10 kg of potassium permanganate, 25 kg of polyvinyl alcohol, 4 kg of triethanolamine kg, trimethylolpropane 3.5 kg.

[0028] The preparation method of the resin co-solvent is as follows: according to the mass ratio of polysorbate: propylene glycol: polyethylene glycol = 1:3:2, the three are pre-mixed to obtain a mixture, and then it is formulated into a mass fraction of 25 % aqueous solution.

[0029] The production method of the liquid mulch film is as follows:

[0030] (1) Put the montan wax resin in the reaction kettle, add the resin co-solvent, and carry out mechanical stirring at 85°C, the stirring speed is 65r / min, and the stirring time is 25min.

[0031] (2) After step (1) is completed, add potassium permanganate into the reaction kettle, keep the temperature constant, change the stirr...

Embodiment 3

[0034] The composition and parts by weight of the multifunctional liquid mulch film of Mengtan wax resin in this embodiment are: 200 kg of Mengtan wax resin, 280 kg of resin cosolvent, 16 kg of potassium permanganate, 39 kg of polyvinyl alcohol, and 6 kg of triethanolamine kg, trimethylolpropane 5 kg.

[0035] The preparation method of the resin co-solvent is as follows: according to the mass ratio of polysorbate: propylene glycol: polyethylene glycol = 1:2:4, the three are pre-mixed to obtain a mixture, and then it is formulated into a mass fraction of 20 % aqueous solution.

[0036] The production method of the liquid mulch film is as follows:

[0037] (1) Put the montan wax resin in the reaction kettle, add the resin co-solvent, and carry out mechanical stirring at 90°C, the stirring speed is 70r / min, and the stirring time is 30min.

[0038] (2) After step (1) is completed, add potassium permanganate into the reaction kettle, keep the temperature constant, change the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com